High altitude conformity type sphericity cavity turbine type wind power generator

A wind power generator and turbine type technology, which is applied in the field of high-altitude integrated spherical cavity turbine wind power generators, can solve the problems that the wind power generator is not high from the ground, difficult to install equipment, and cannot be used, and achieve the effect of saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

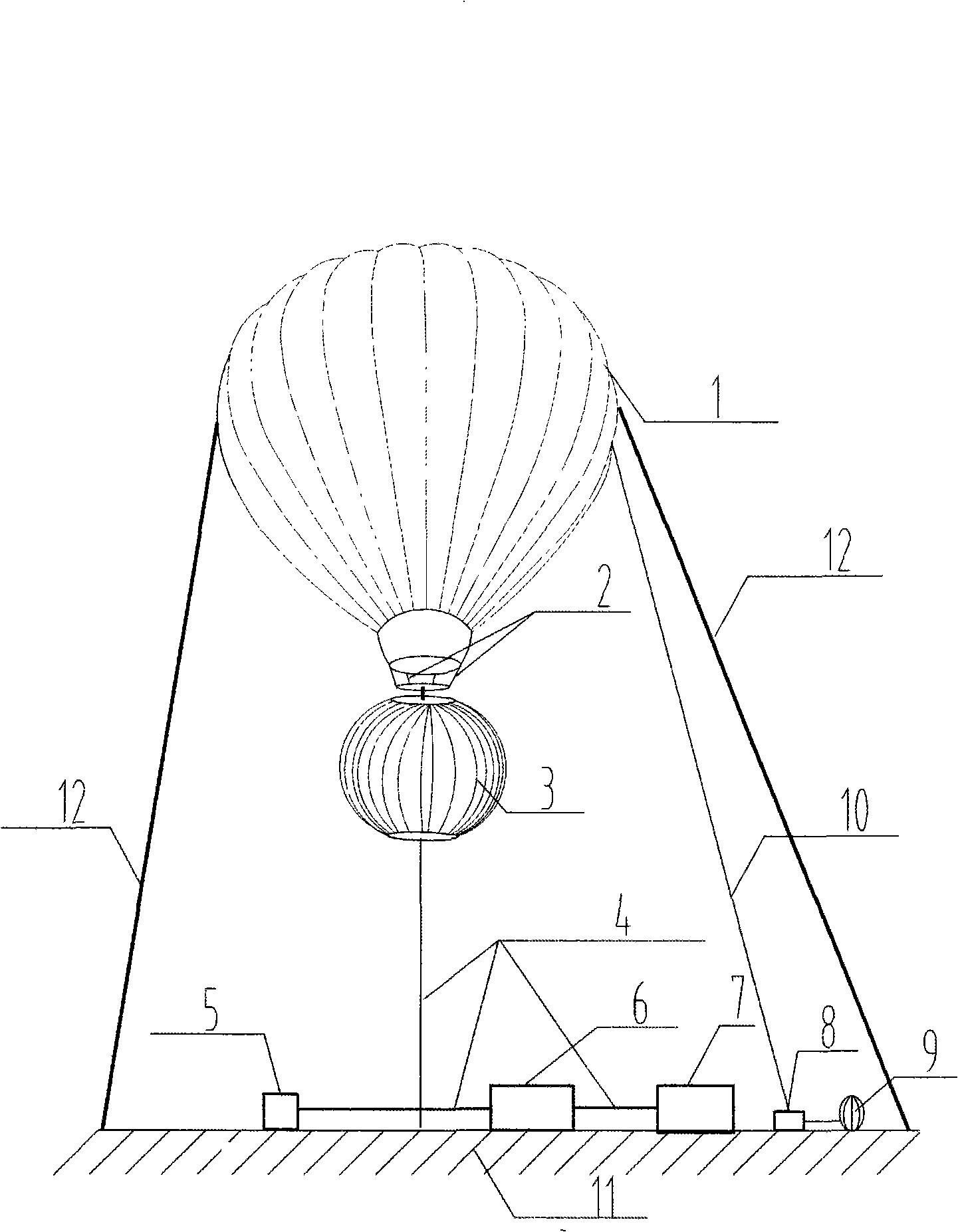

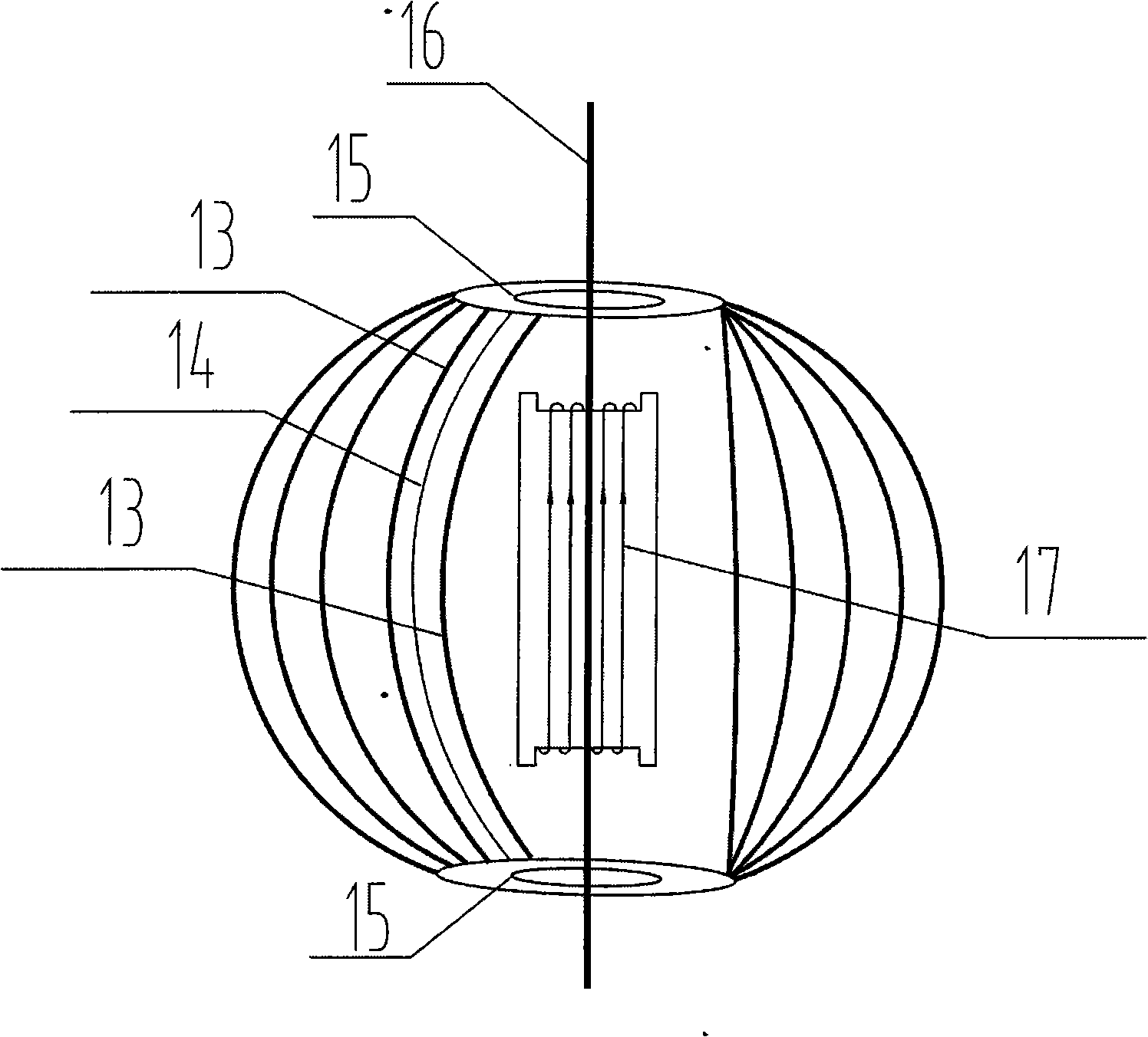

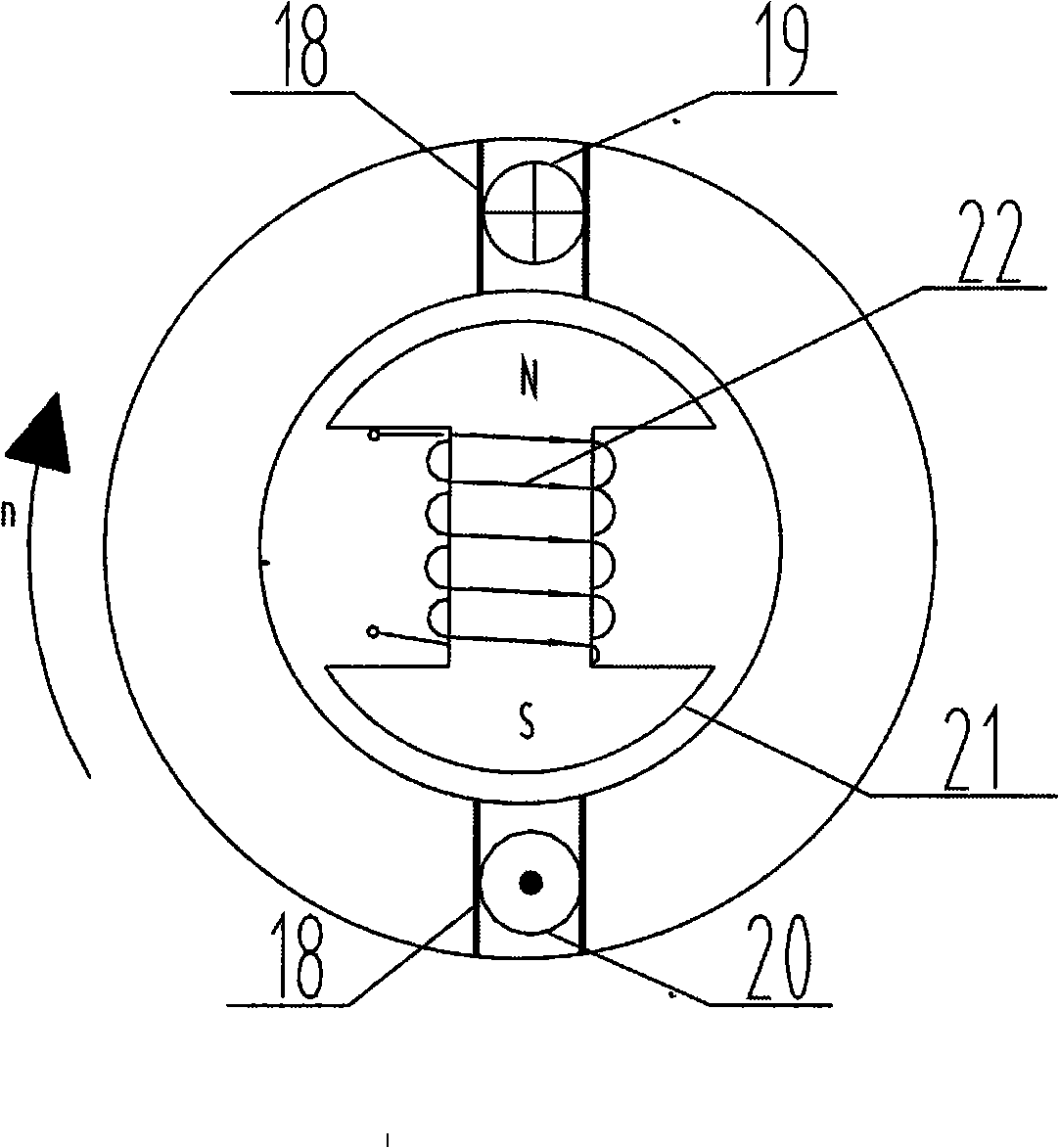

[0021] The invention provides a power generating device capable of fully utilizing high-altitude wind energy. refer to figure 1 , figure 2 , image 3 , which consists of a helium balloon 1, a load cable 2, an integrated spherical cavity turbine wind generator 3, a cable 4, a controller 5, a transformer 6, a storage battery 7, an air pump 8, a spare helium balloon 9, an air duct 10, the ground 11, fixed rope 12 and other parts. The load cable 2 is connected to the helium balloon 1 and the integrated spherical cavity turbine wind generator 3 .

[0022] The helium balloon 1 raises the integrated spherical cavity turbine wind power generator 3 to high altitude, and utilizes the strong wind force at high altitude and the advantages of low starting wind speed, high safe wind speed, and directional rotation of the spherical cavity turbine fan, and makes full use of the high altitude wind power generation.

[0023] The integrated spherical cavity turbine wind power generator 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com