Improved diesel engine piston

A diesel engine and piston technology, which is applied in the field of diesel engines, can solve the problems of pulling, burning, and knocking on the sliding surface, so as to avoid the effect of knocking the cylinder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

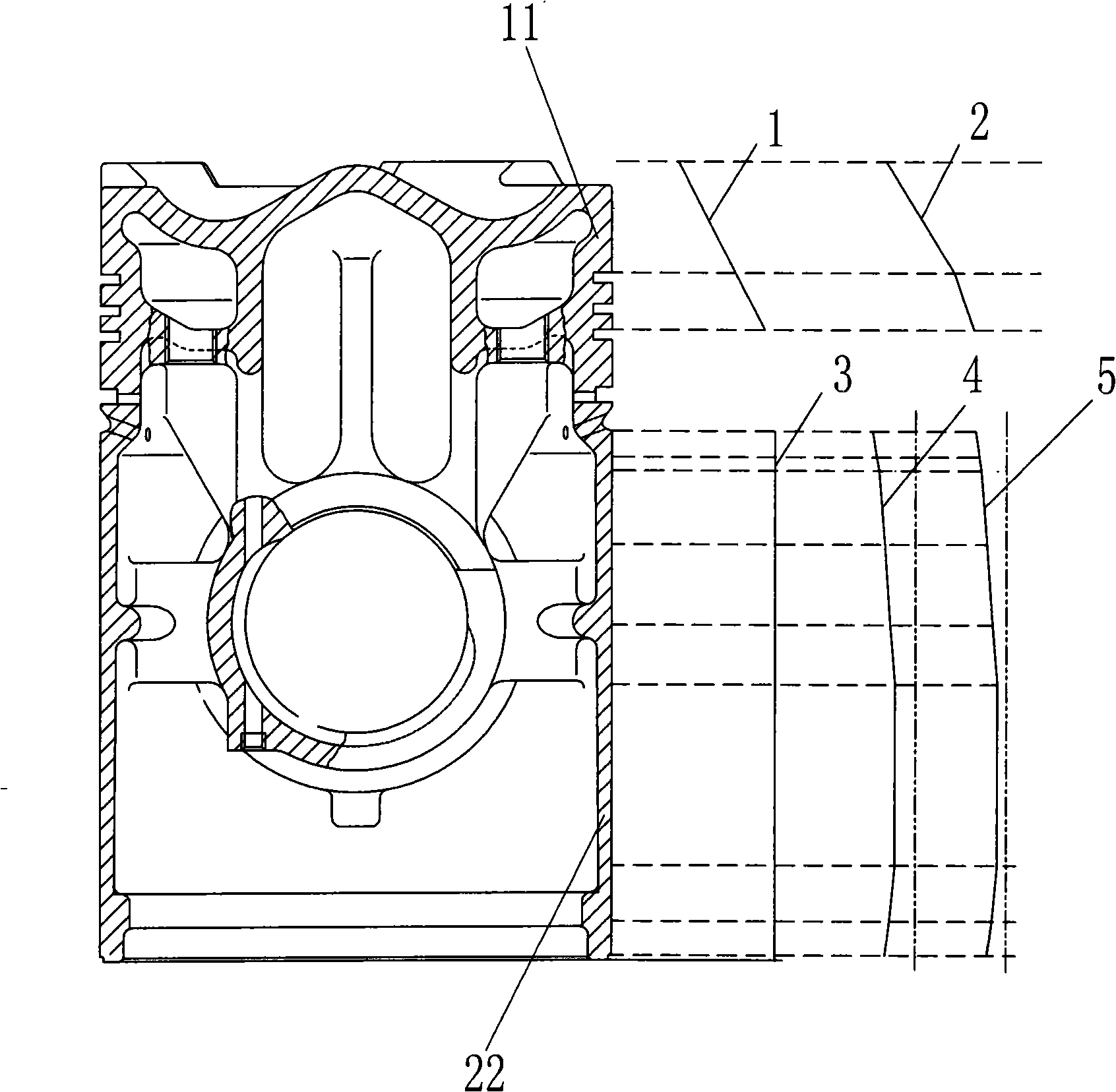

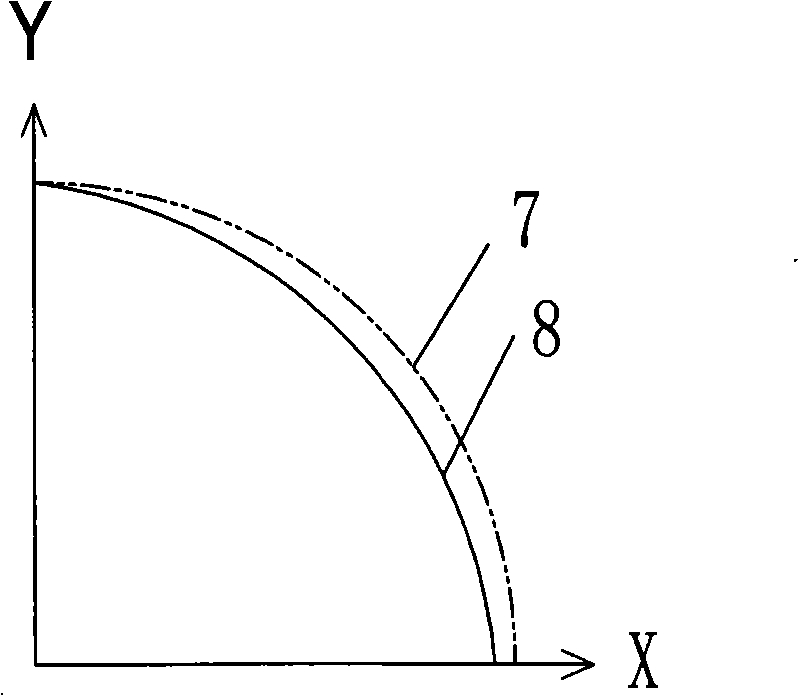

[0012] Example: such as figure 1 Shown, a kind of improved diesel engine piston comprises piston head 11 and piston skirt 22, and the cross-section of piston head 11 and piston skirt 22 is all approximately ellipse, and piston skirt 22 is processed as minor axis along The direction of the piston pin axis, the long axis is along the direction perpendicular to the piston pin axis, such as figure 2 As shown, the cross-sectional profile 8 of the piston skirt 22 is also approximately an elliptical profile; the longitudinal profile 2 of the piston head 11 is a stepped line, the longitudinal profile of the piston skirt 22 is also a stepped profile, and the longitudinal profile of the piston skirt 22 It includes the short-axis profile 4 of the piston skirt and the long-axis profile 5 of the piston skirt.

[0013] The longitudinal profile 2 of the piston head 11 is a two-stage stepped line, and the short-axis profile 4 of the piston skirt and the long-axis profile 5 of the piston ski...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com