Filtrating process of copper electrolysis supernatant

A technology of electrolyte and supernatant, applied in electrolysis process, photography process, electrolysis components, etc., can solve the problem of high content of suspended solids and achieve the effect of cathode copper quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

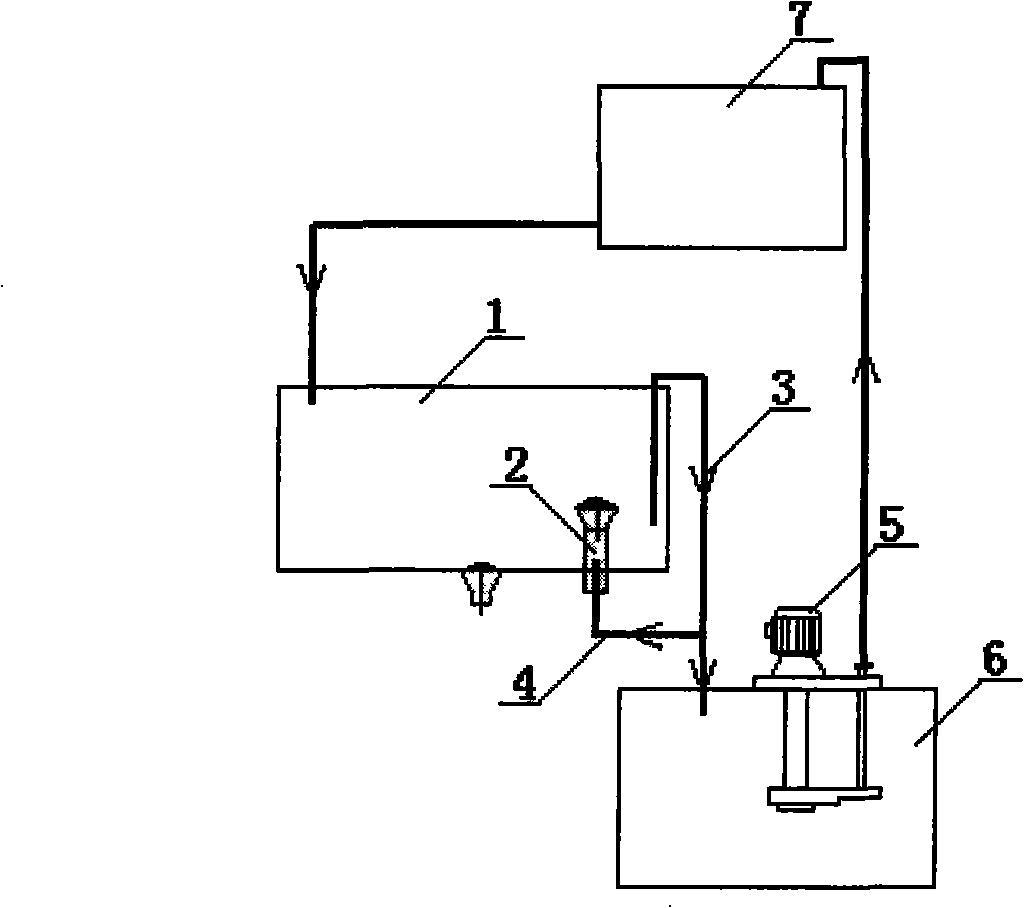

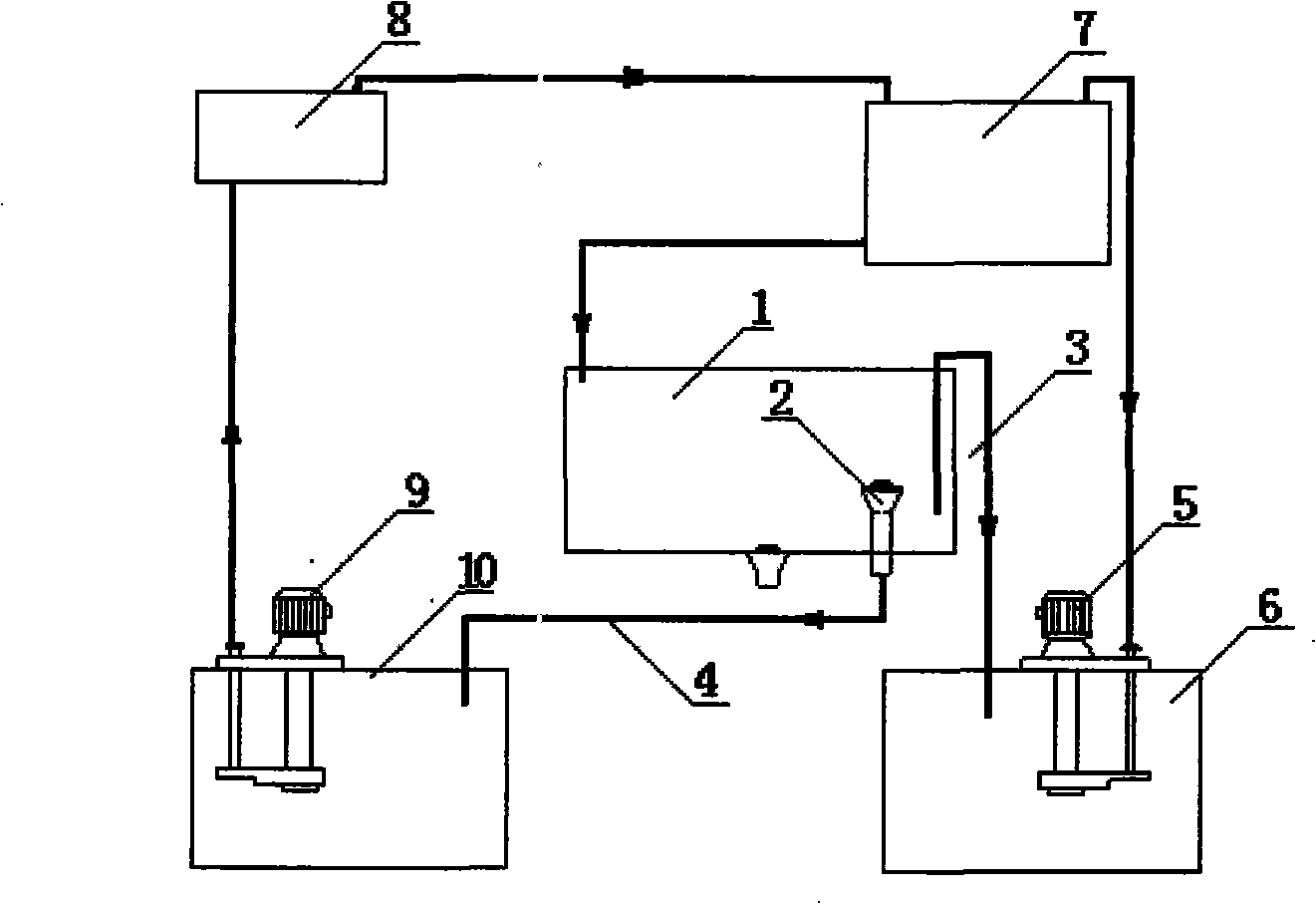

[0009] The electrolyte flows from the electrolytic tank 1 to the lower tank 6 through the circulation pipe 3, and then is sent to the upper tank 7 by the circulation pump 5, and then the electrolyte flows into the electrolytic tank 1 from the upper tank 7, thus forming a circulation system. When cleaning the tank, open the valve 2, and the turbid electrolyte in the electrolytic tank 1 will lead to the clear liquid storage tank 10 through the supernatant liquid pipe 4, so that the supernatant liquid in the electrolytic tank can be recovered separately to the storage tank 10, and the filter pump 9 Send to the filter press 8 to filter and then return to the high tank 7 of the electrolyte circulation system to enter the circulation system, realizing the new process of returning the supernatant to the system after filtering.

[0010] The supernatant in the electrolytic cell 1 is collected separately by using pipelines, and can be filtered through a filter press for 8 rows, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com