Polymerization tank temperature distribution estimation apparatus and polymerization tank temperature distribution estimation program

A technology of temperature distribution and polymerization tank, applied in thermometers, thermometers that give differential values, weighing equipment for automatic feeding/discharging, etc., can solve problems such as failure to consider reaction, failure to polymerize tank temperature distribution, etc., to achieve The effect of reduced calculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

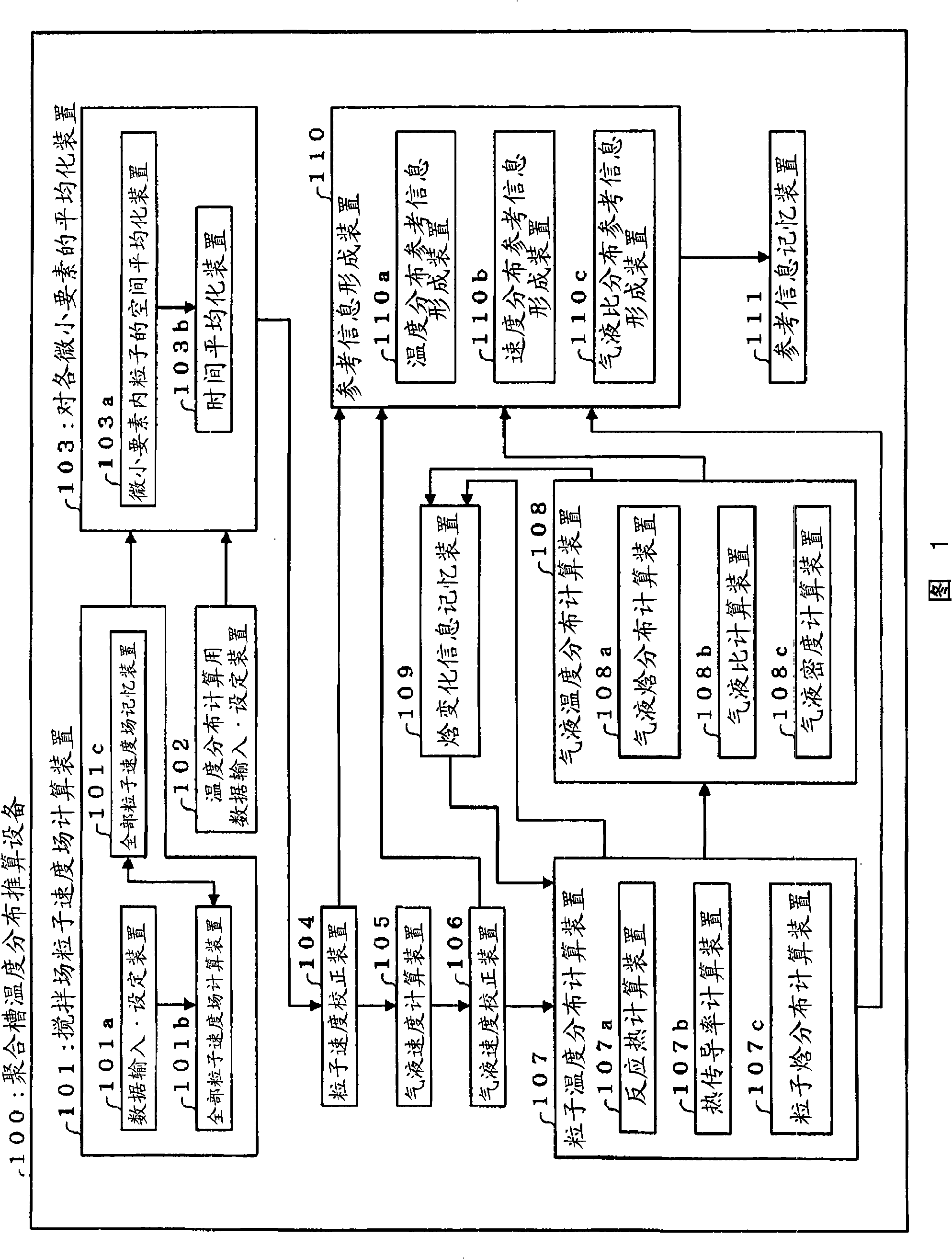

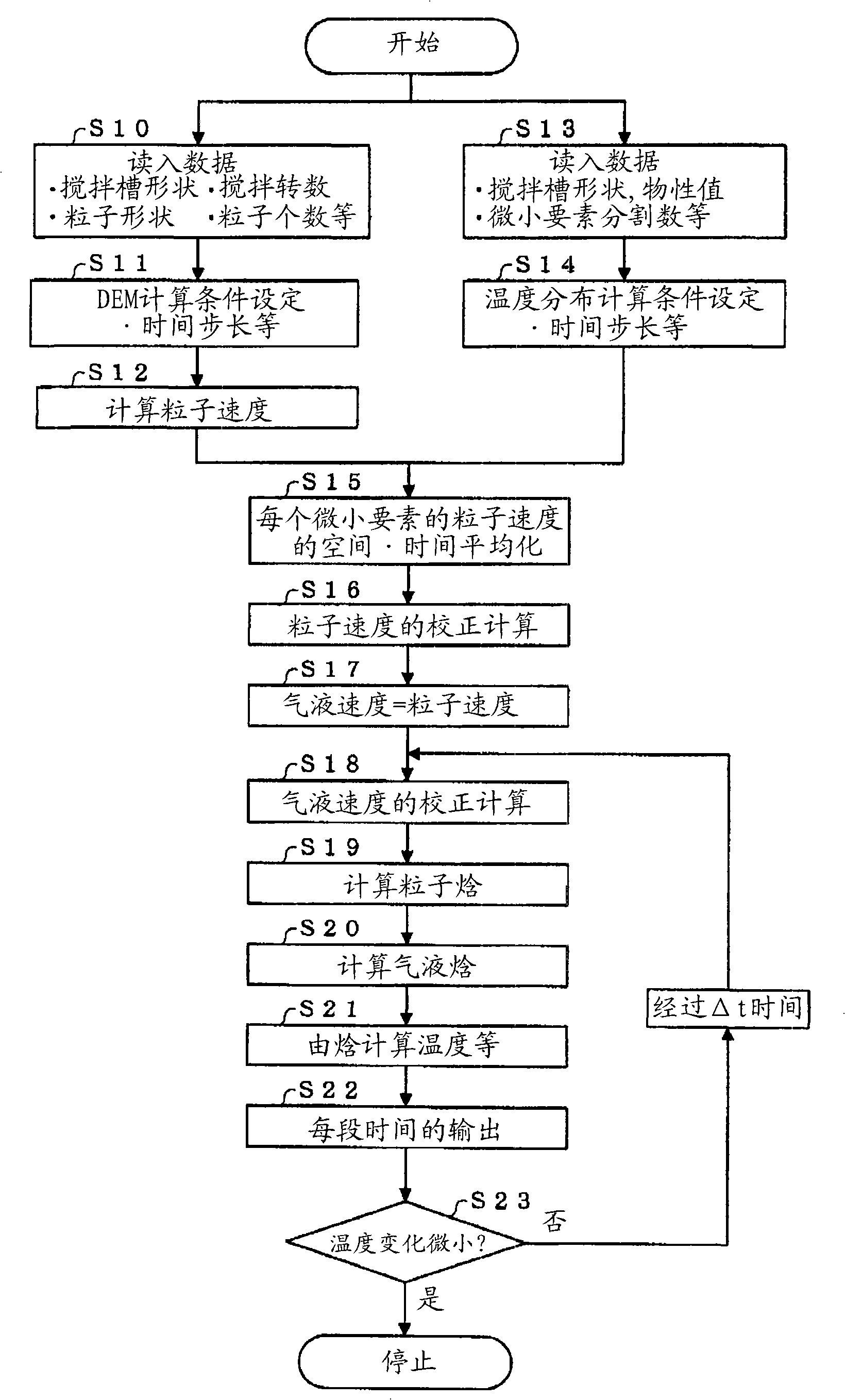

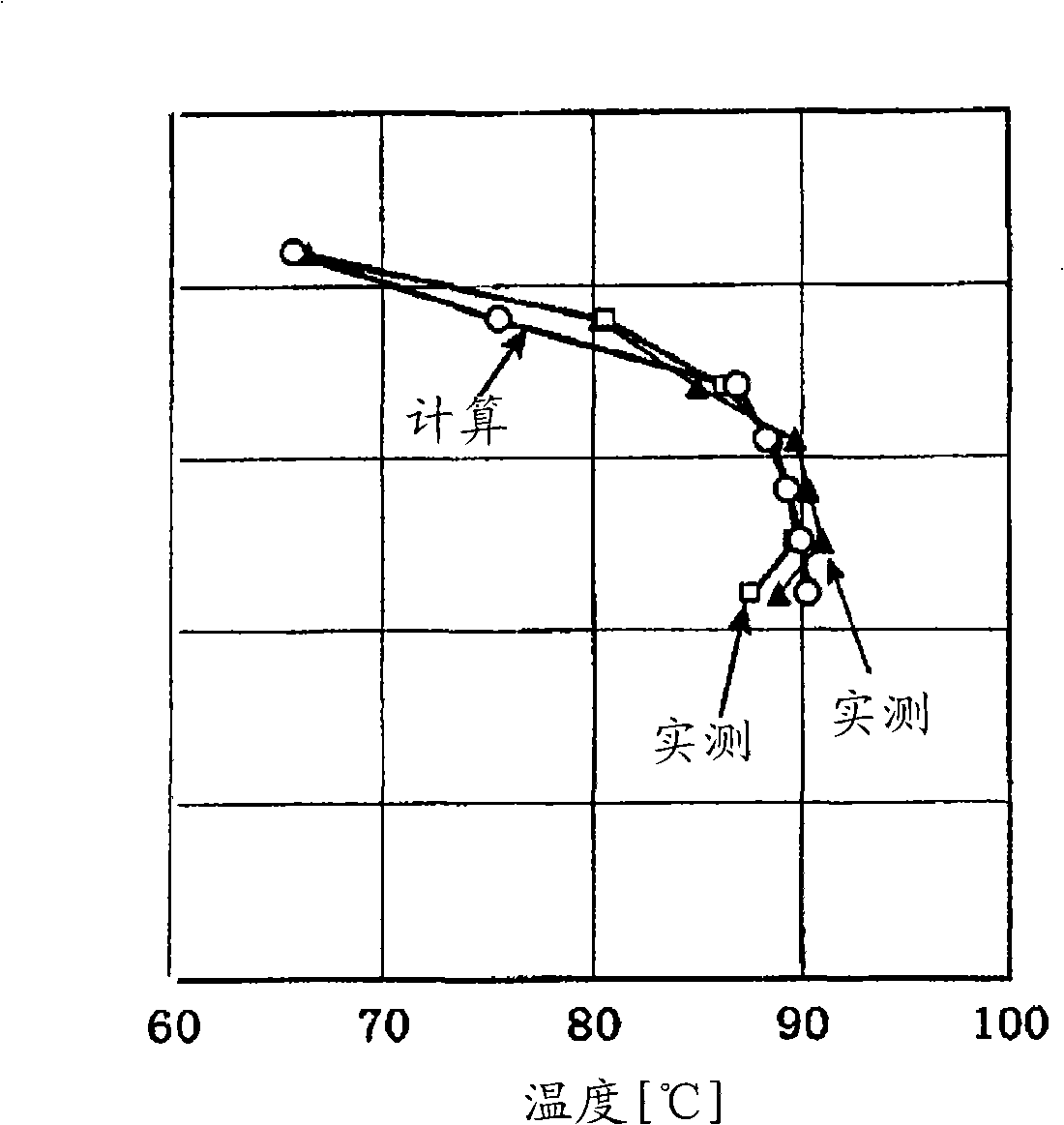

[0070] Hereinafter, preferred embodiments of the polymerization tank temperature distribution estimation device of the present invention will be described with reference to the drawings.

[0071] It should be noted that the polymerization tank temperature distribution estimation device of the present invention shown in the following embodiments is operated by a computer controlled by a program. The CPU of the computer sends instructions to each component of the computer based on the program, and performs predetermined processing necessary for the operation of the polymerization tank temperature distribution estimation device, such as particle velocity calculation processing, and spatial and temporal averaging of particle velocity for each minute element processing, particle velocity correction calculation processing, gas-liquid velocity correction calculation processing, particle enthalpy calculation processing, gas-liquid enthalpy calculation processing, temperature from entha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com