Hydrophobic self-cleaning sanitary ware glaze and preparation thereof

A self-cleaning technology for sanitary ware, which is applied in the glaze field of porcelain or stoneware sanitary ware, can solve the problems of poor wear resistance and shedding of the film layer, and achieve good hydrophobicity, reduce surface energy, and long-lasting self-cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

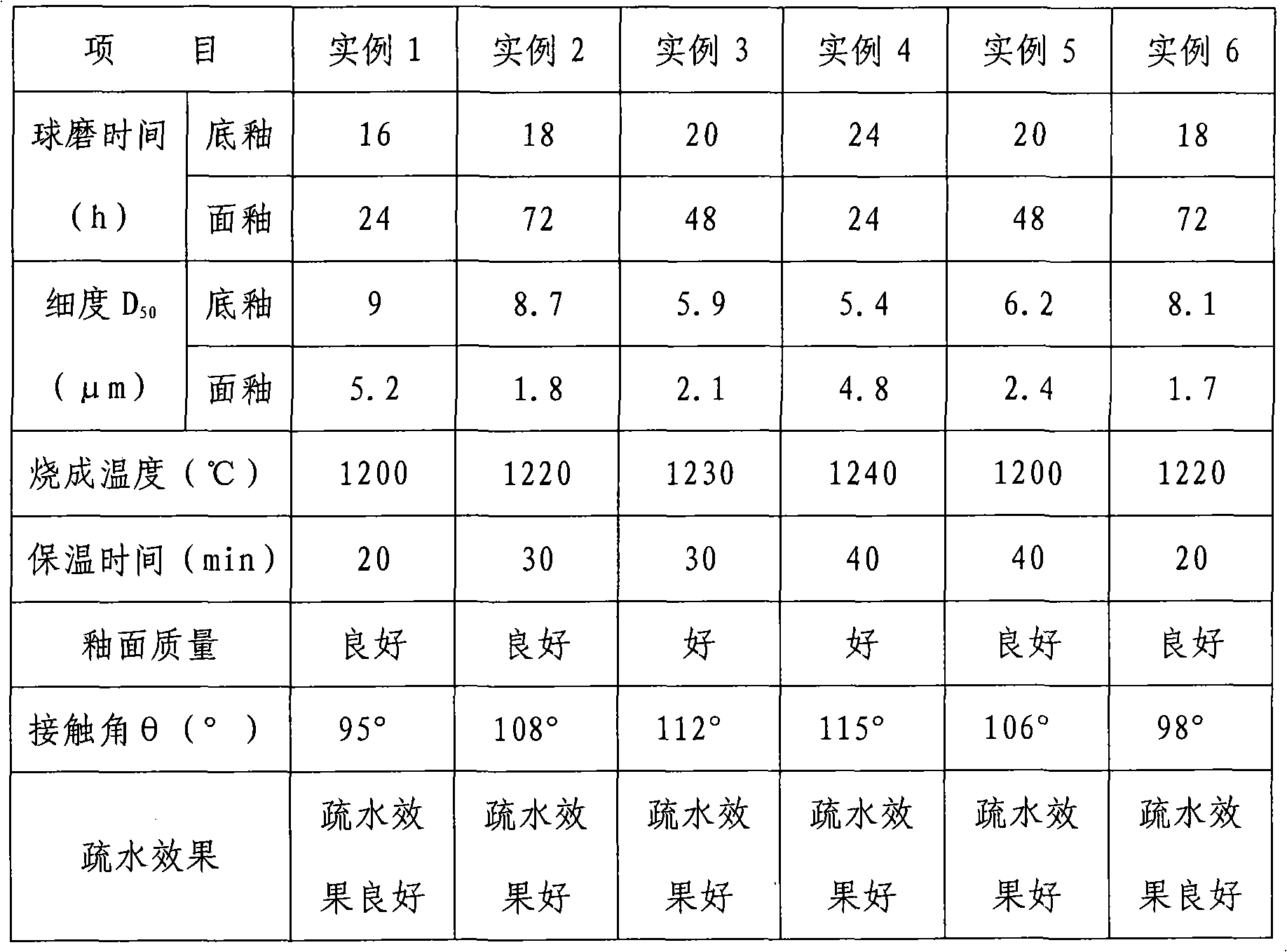

[0023] Prepare the raw materials according to the composition in Table 1-3, and process parameters in Table 4. After crushing, mixing ball milling, sieving, spraying the first layer of opaque glaze, drying, spraying the second layer of transparent glaze, drying, and firing to obtain the hydrophobic performance Self-cleaning sanitary ware glaze.

[0024] Table 1 The composition of opacified glaze material formula (mass fraction%)

[0025] raw material

Example 1

Example 2

Example 3

Example 4

Example 5

Example 6

40

32

34

36

32

40

16

22

20

18

18

16

Aluminum oxide

2

3

3

4

3

2

Suzhou soil

6

7

8

6

6

4

13

14

14

13

15

15

3

3

4

4

5

5

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com