Injection moulding method using cold-hot flow passage

A technology of cold runner and hot runner, applied in the field of injection molding, can solve the problems of material waste, waste section length, etc., and achieve the effect of ensuring economy, reducing injection pressure, and ensuring fillability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

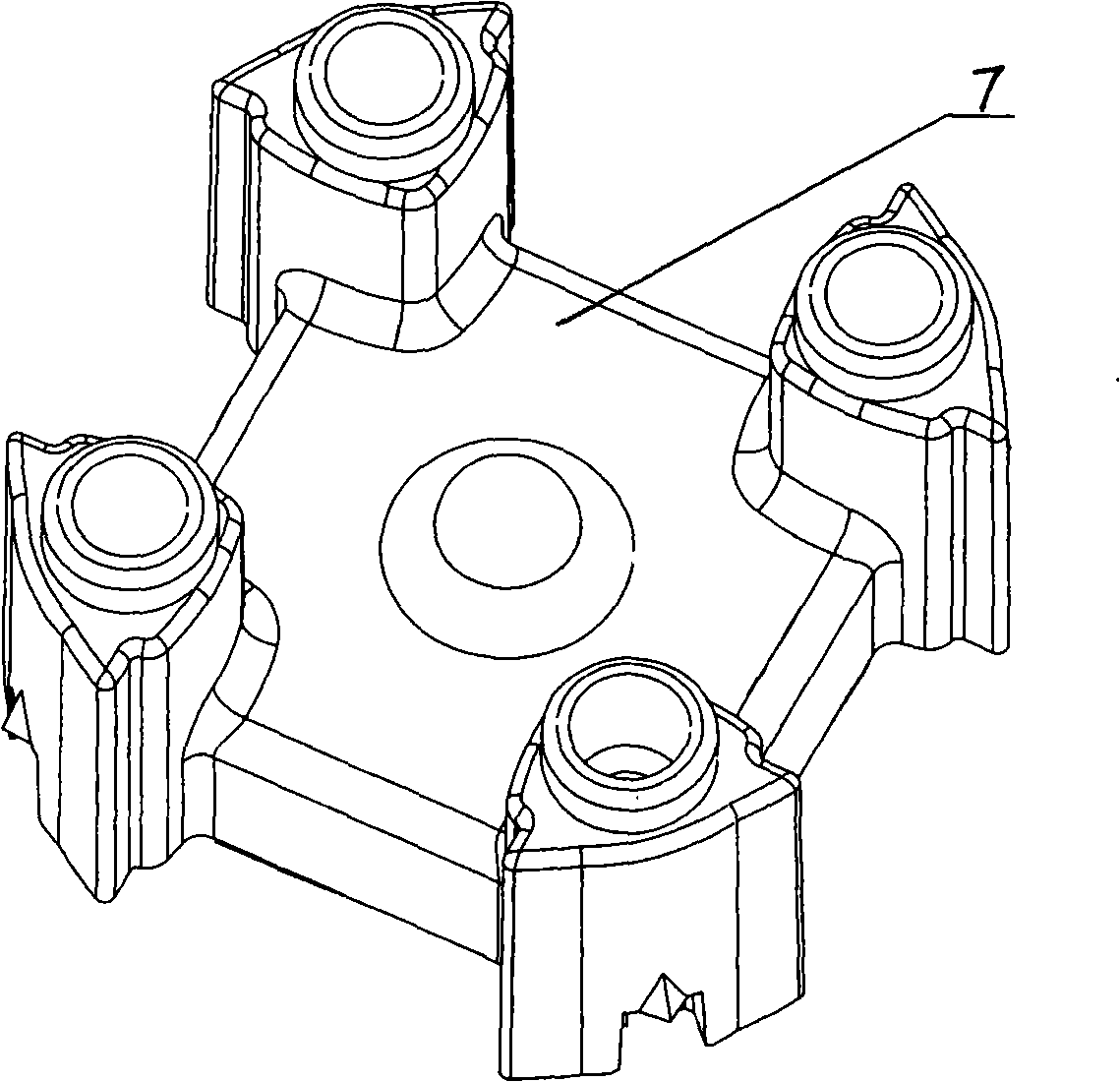

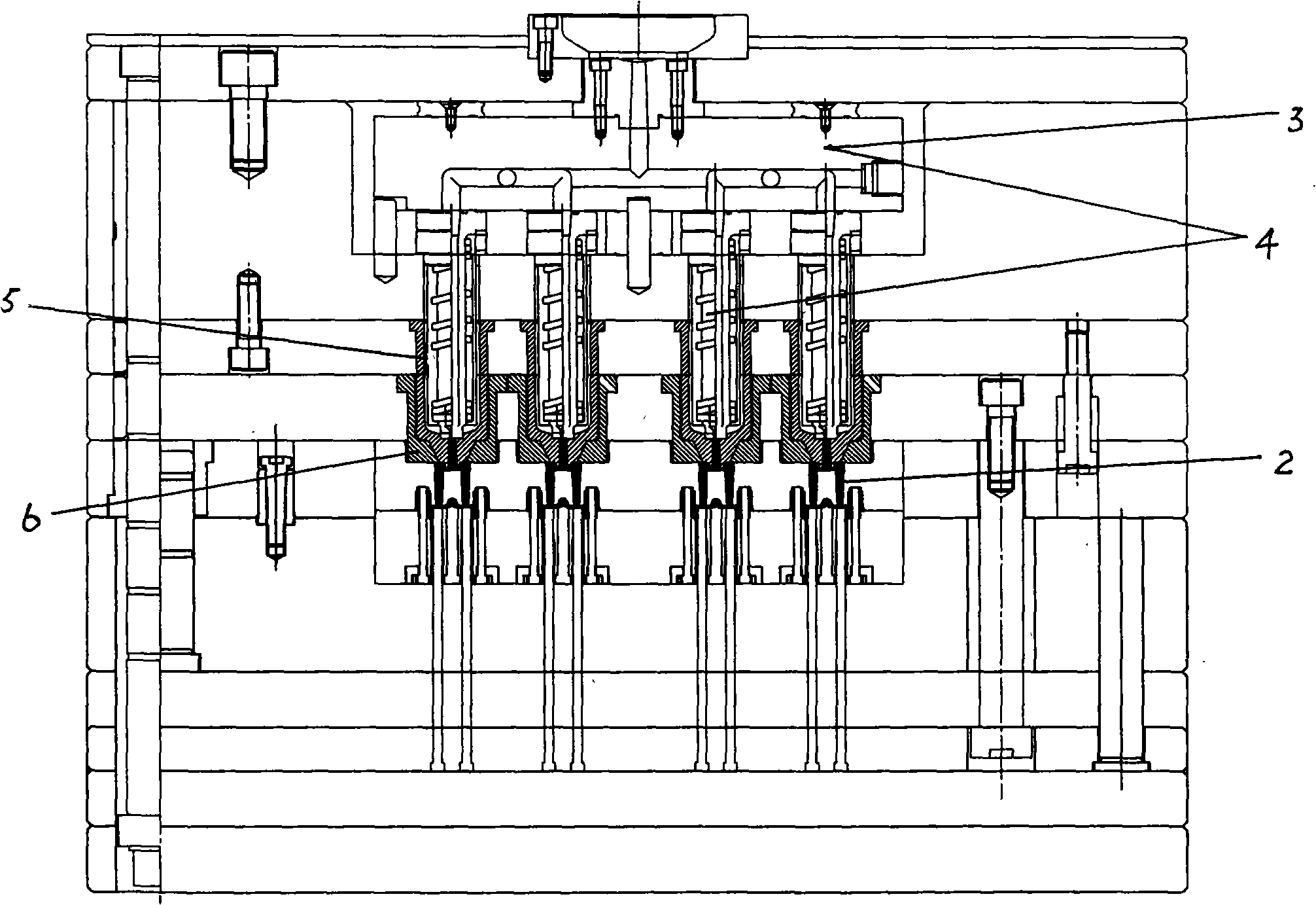

[0016] Such as image 3 Shown is a schematic diagram of the structure of the injection molding runner device of the present invention. The method for injection molding using hot and cold runners is characterized in that the method is:

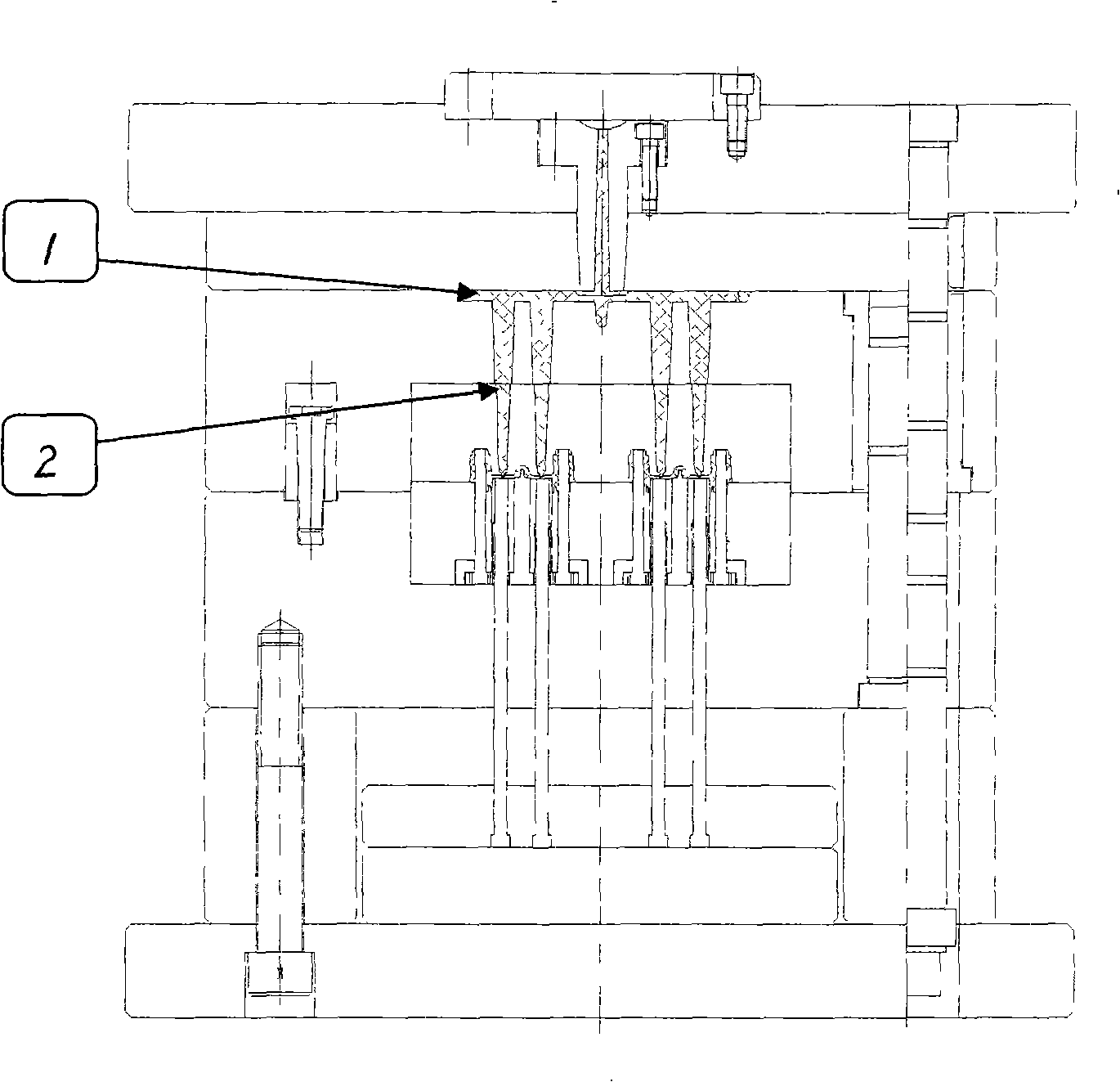

[0017] In the first step, transition runners 4 are added to the upper ends of the four cold runners 2 of the original injection mold, and runner transition sleeves 5 and degumming sleeves 6 are installed outside the transition runners 4, such as Figure 4 shown;

[0018] In the second step, connect the upper ends of all the transition runners 4 to a hot runner 3 .

[0019] In the present invention, most of the strokes of the main channel 2 and the sub-runner 4 are transferred by the hot runner, that is, the injection molding liquid in the molten state is used for injection molding. The injection molding liquid in the molten state can be heated by electric heating, and the heating temperature is 260°C- 300°C, keep the injection molding liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com