Cellooligosaccharide-containing composition

一种纤维寡糖、组合物的技术,应用在耐热,油性也优异,能够解决影响肠内细菌等问题,达到提高屏障功能、提高脂质代谢性、促进恢复的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

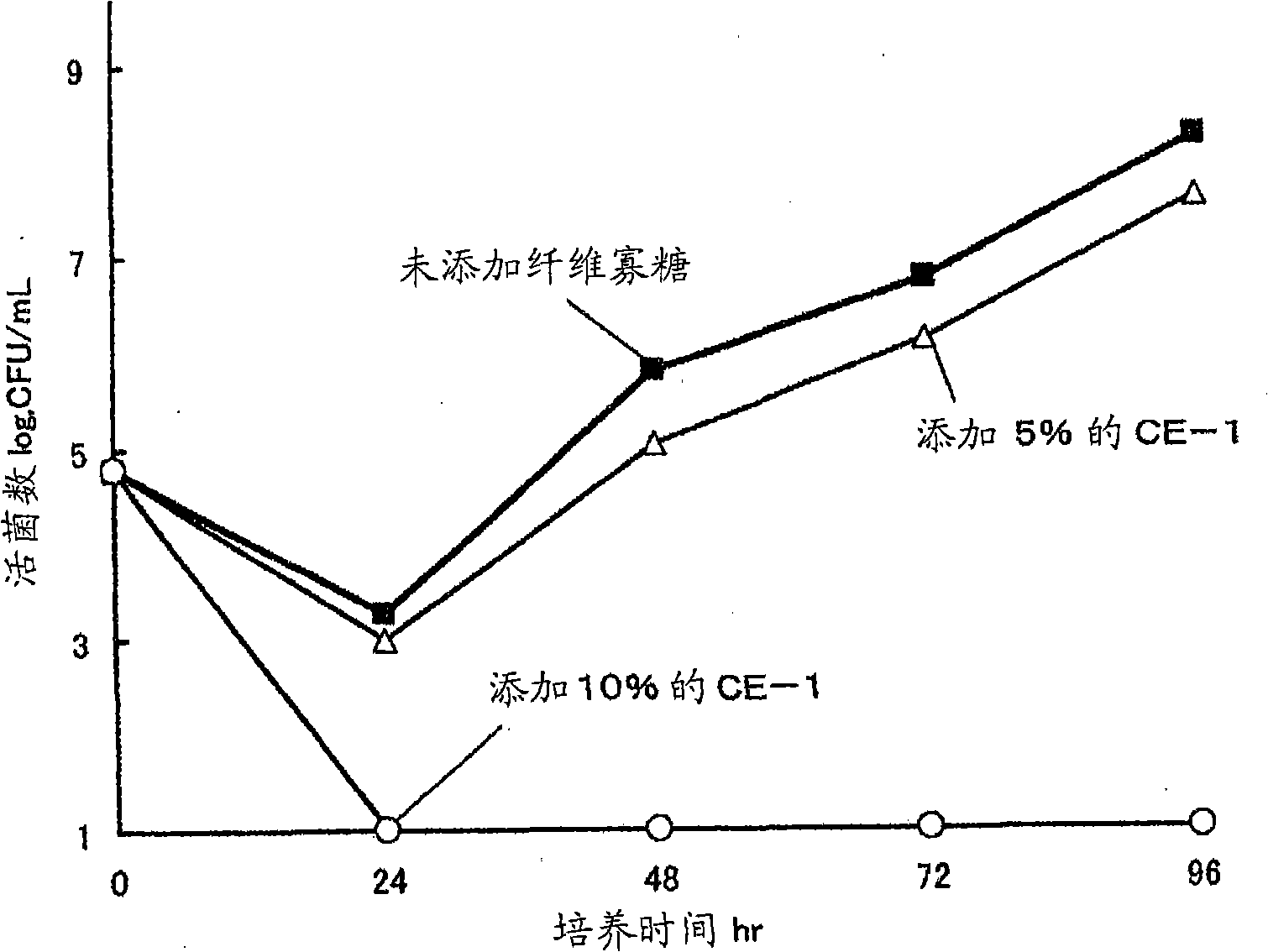

Image

Examples

manufacture example 1

[0250] Tricoderma reesei (Tricoderma reesei) NBRC31329 was inoculated in ordinary agar medium, and after culturing at 37°C for 7 days, spores of 1 inoculation loop were taken from the surface of the medium, and inoculated into the solution by suspending and dissolving in a total of 1 L of purified water. 1g polypeptone, 0.5g yeast extract, 2g potassium dihydrogen phosphate, 1.5g ammonium sulfate, 0.3g magnesium sulfate, 0.3g calcium chloride, 1mL trace elements (6mg boric acid, 26mg ammonium molybdate 4 hydrate, 100mg chloride Iron oxide hexahydrate, 40 mg of copper sulfate 5 hydrate, 8 mg of manganese sulfate 4 hydrate, 200 mg of zinc sulfate 7 hydrate dissolved in a total of 100 mL of purified water), 1 mL of ADEKANOL (a thickener) and In a culture medium obtained with 10 g of crystalline cellulose (manufactured by Asahi Kasei Chemical Co., Ltd., trade name PH-101), culture was carried out at 28° C. for 5 days with aeration and stirring. During the cultivation process, the p...

Embodiment 1

[0255] 100 mL of the cellooligosaccharide aqueous solution obtained in Production Example 1 was introduced into a 200 mL glass flask, and cooled from 70° C. to 25° C. at a rate of 10° C. per hour while stirring (the solubility parameter δ of the solvent was 22.2). Filter the cellooligosaccharide crystallized from the aqueous solution at 25°C under reduced pressure, dry it with a ventilated dryer at 40°C, pulverize it with a mortar, sieve it with a sieve with a mesh of 150 μm, and sieve the powder with a mesh Fine powder was removed through a 45 μm sieve to obtain cellooligosaccharide powder. 500 mg of the obtained cellooligosaccharide powder was introduced into a Φ1.1 mm steel cylindrical socket, and pressed at 150 MPa for 10 seconds using a Φ1.1 mm flat pestle to measure the hardness of the obtained molded body. (The average L / D is 1.7, the bulk density is 0.43g / mL, the cellobiose content is 99% by mass, the cellotriose-cellohexaose content is 0.1% by mass, the glucose conten...

Embodiment 2

[0257] Using commercially available cellobiose (manufactured by Aldrich, with a purity of 98% by mass), it was dissolved in 70°C water at a concentration of 30% by mass in a 200mL glass flask so that the total amount was 100mL, and the temperature was increased at 10°C per hour. After cooling from 70°C to 25°C, add an isopropanol / ethanol solution with a volume mixing ratio of 50 / 50 at a rate of 10 g per minute so that its concentration relative to water is 50% by mass, at a rate of 10°C per hour Cooling rate from 70°C to 25°C (solubility parameter δ of the solvent is 16.6). The cellooligosaccharide crystallized in the aqueous solution was filtered under reduced pressure, dried, pulverized, and sieved in the same manner as in Example 1 to obtain a cellooligosaccharide powder. About the obtained cellooligosaccharide, the molded body hardness was measured similarly to Example 1. (The average L / D is 2.3, the bulk density is 0.54g / mL, the cellobiose content is 99% by mass, the cel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com