Directly-down back light module unit, LCD device and light tube assembling method

A technology of a liquid crystal display device and a backlight module, which is applied to lighting devices, lighting auxiliary devices, components of lighting devices, etc., and can solve problems such as the unfavorable application of large-sized backlight modules, and the falling off of hooks 250 on the left and right sides. , to achieve the effect of improving production yield and product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The structure of the direct type backlight module and the installation process of the light tube will be taken as an example below to illustrate the relevant technical points of the present invention.

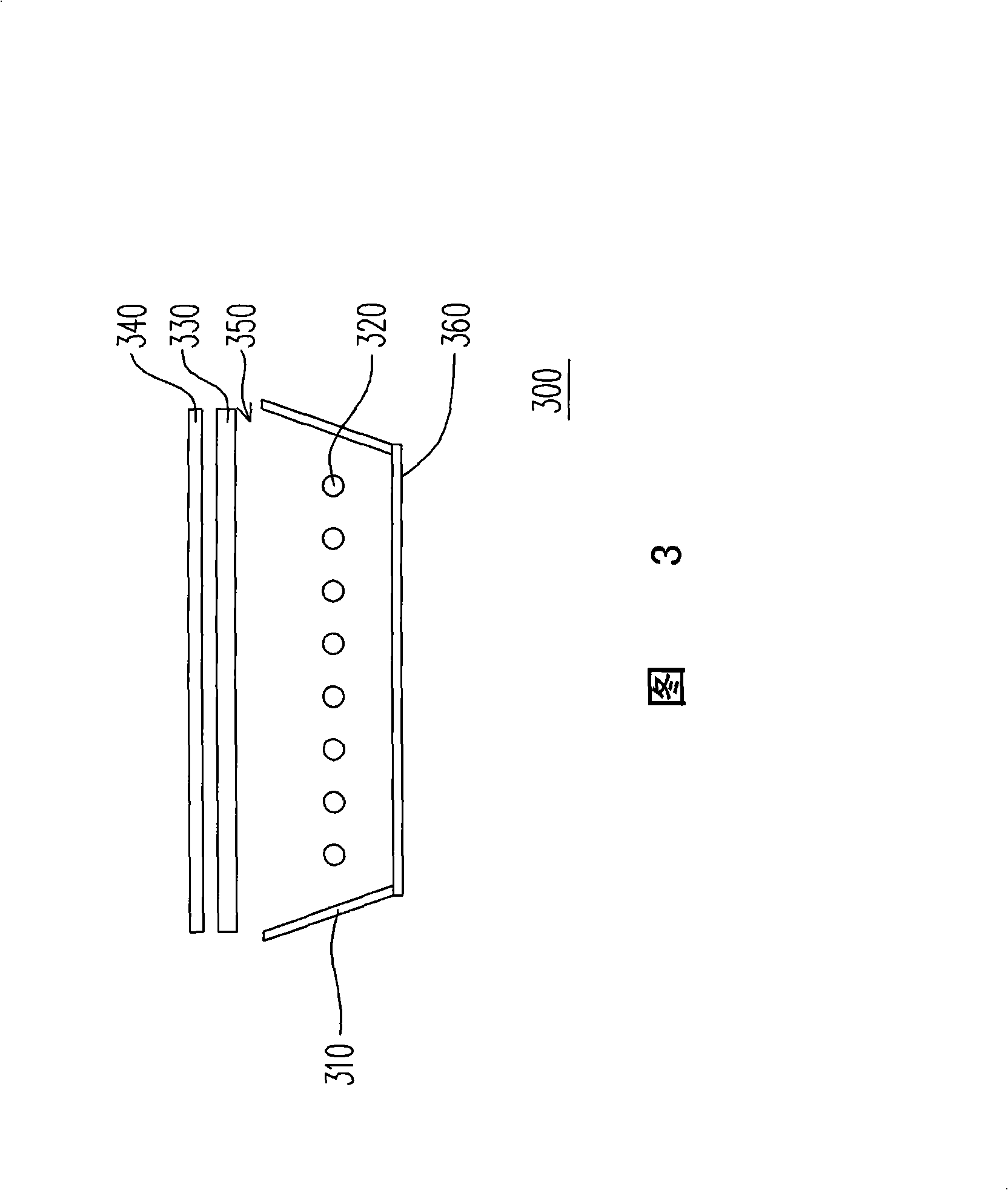

[0065] FIG. 3 is a schematic cross-sectional view of a direct type backlight module of the present invention. Referring to FIG. 3 , the direct-lit backlight module 300 of this embodiment includes a light box 310 and a plurality of light tubes 320 and other components. The light box 310 has an opening 350 and a bottom plate 360 opposite to each other, and the light tube 320 is disposed in the light box 310 . The opening 350 of the light box 310 can optionally be equipped with a diffuser 330 , which functions to improve the distribution of the surface light source provided by the light tube 320 , so that the light output is more uniform. In addition, an optical film 340 may also be disposed on the diffusion plate 330 . Generally speaking, the optical film 340 may includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com