Freestyle belt sheave

A pulley, free technology, applied in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problem of inconsistency in the effective length of torque transmission, slipping failure of one-way bearings and mandrels, and affecting the gear train shaft To avoid problems such as positioning accuracy, to avoid slipping failure, prevent displacement and fall off, and achieve the effect of small contact stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

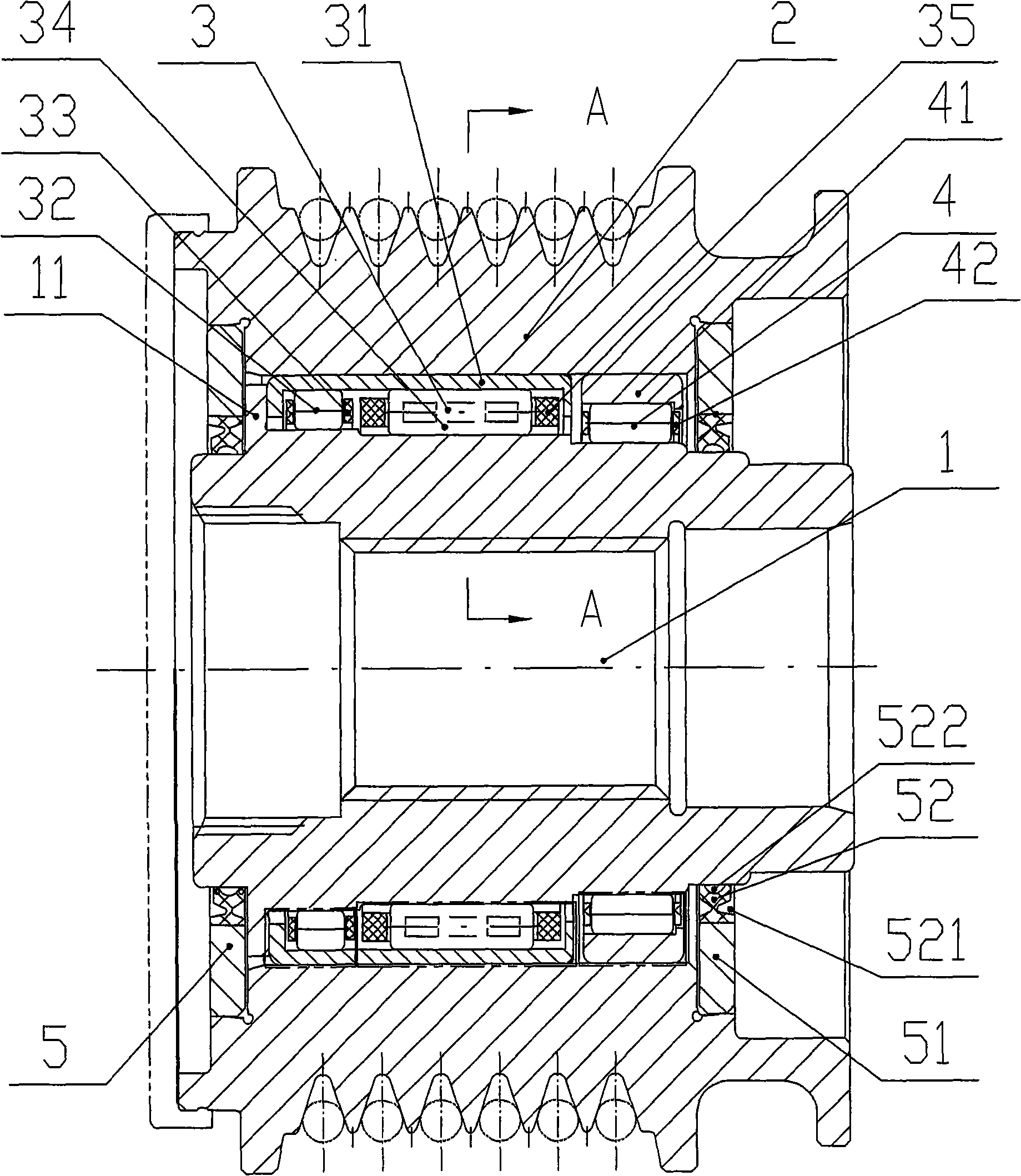

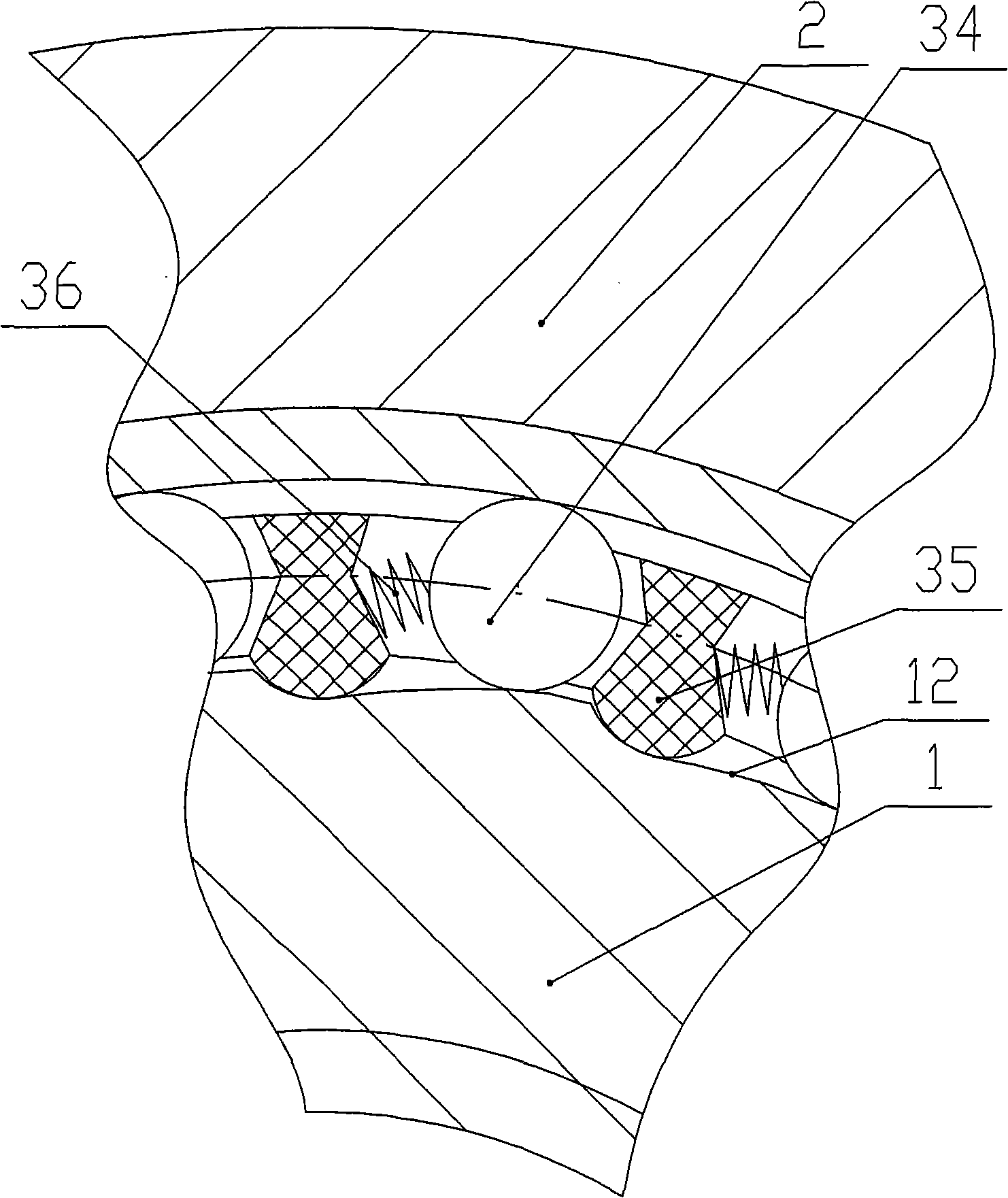

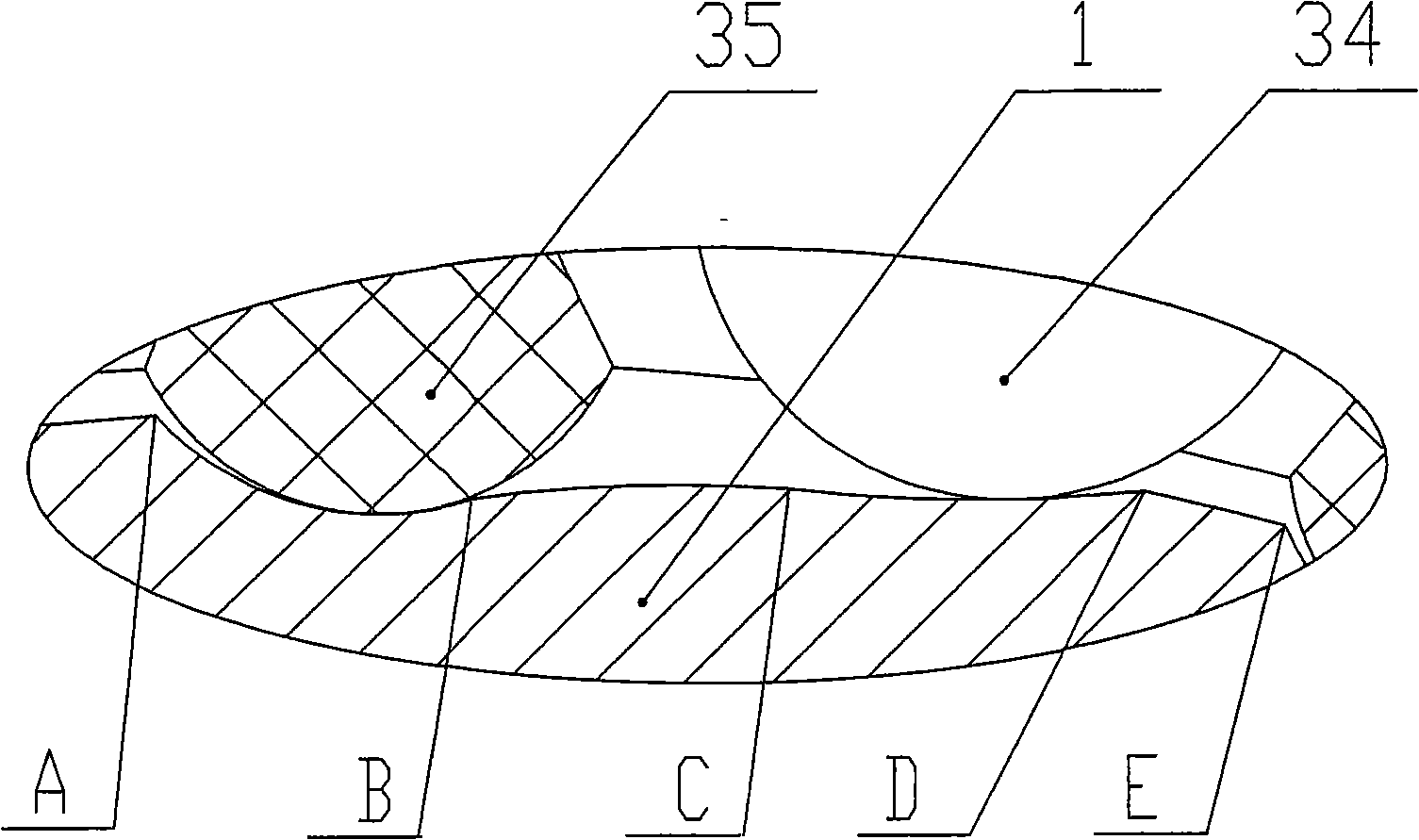

[0026] Such as figure 1 The shown free pulley of the present invention has an integral mandrel 1 fixedly sleeved at the end of the rotating shaft of the alternator, and a driven pulley is arranged concentrically with the integral mandrel 1 outside the circumference of the integral mandrel 1 2. A one-way bearing 3 and a support bearing 4 are arranged between the integral mandrel 1 and the driven pulley 2. The outer ring of the one-way bearing 3 is a double rib outer ring 31, and the outer ring of the support bearing 4 is a solid single Rib outer ring 41, double rib outer ring 31, and single rib outer ring 41 all have an interference fit with the inner hole of driven pulley 2, and the front part of the integral mandrel 1 has a protrusion for axial positioning of one-way bearing 3. The shoulder 11, the inner ring of the one-way bearing 3, the inner ring of the support bearing 4 and the integral mandrel 1 are integrally structured, and the integral mandrel 1 and the driven pulley ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com