Multifunctional suction disc equipment

A suction cup, multi-functional technology, applied in suction cups, connecting components, mechanical equipment, etc., can solve the problems of difficult to fix and hang heavy objects, difficult to handle, etc., and achieve the effects of low cost, high work efficiency and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

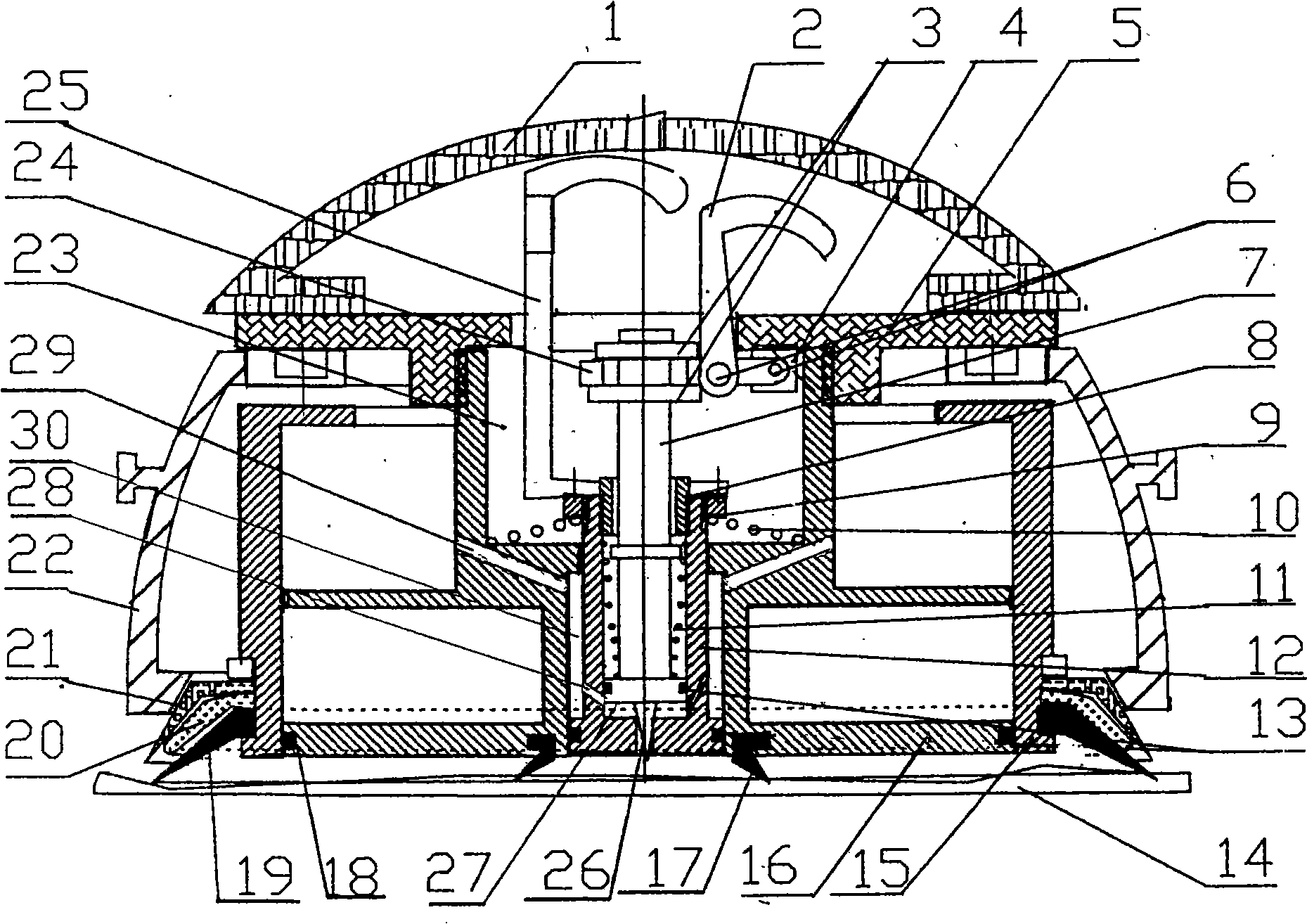

[0009] From figure 1It can be seen from the figure that: a multifunctional suction cup device is characterized in that a ⊥-shaped main piston 16 is installed in the inner cavity of the main piston cylinder 15 with a central through hole on the top, the lower part of the main piston 16 is a disc body and the upper part is a Cylinder, the upper end section of the cylinder of the main piston 16 stretches out the central through hole of the main piston cylinder 15, the upper end section of the cylinder of the main piston 16 has external threads, and the upper and lower sections are vertically set at the central part of the main piston 16. Little upper step hole 23 and lower step hole 30, offer through hole between upper and lower step hole 23,30, offer main annular groove on the disc body upper circumference of main piston 16, the disc body of main piston 16 is divided into The upper disk and the lower disk, the upper disk plays the role of limiting and guiding when the main pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com