Scale culture and promotion technique for trans TNF-alpha gene blue algae growth and gene expression by light reactor

A gene expression and photoreactor technology, which is applied in the field of photoreactor large-scale cultivation and promoting the growth and gene expression of TNF-α gene cyanobacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

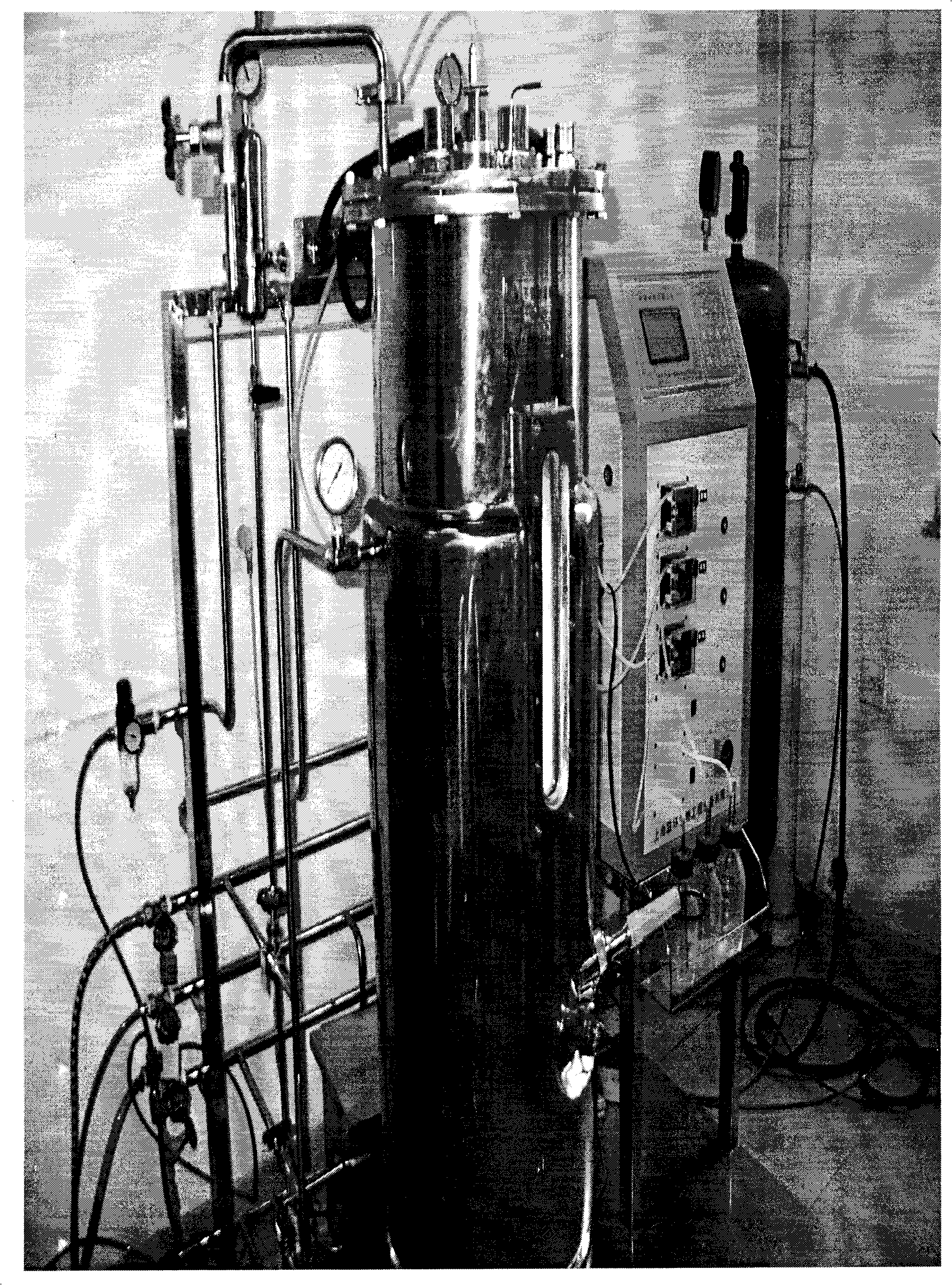

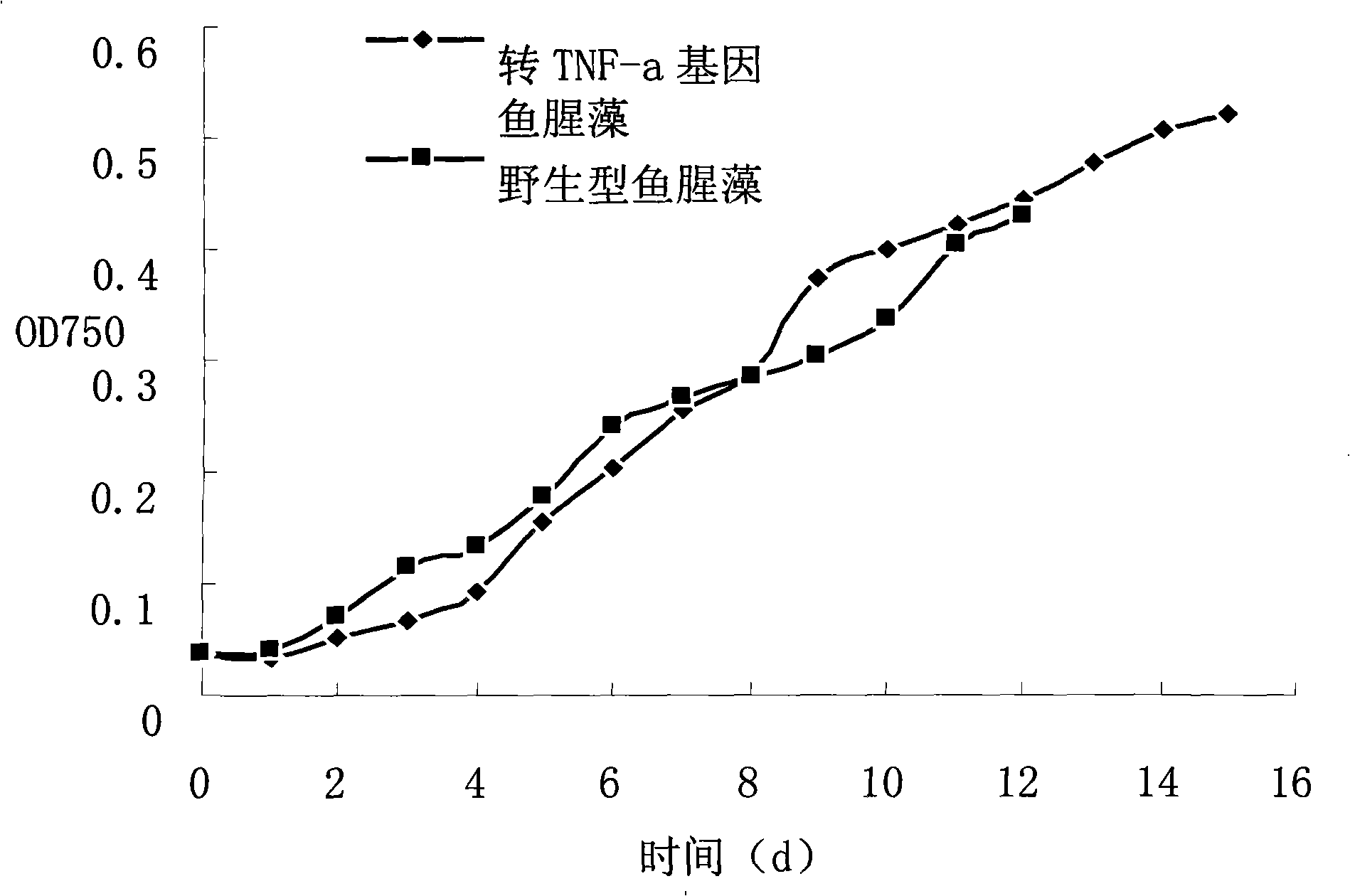

[0023] A closed 100L photoreactor was established to cultivate cyanobacteria. The main reactor is cylindrical, with a height of 110 cm, a diameter of 35 cm, and a usable volume of 70 L. There are three built-in lamp tubes, and each lamp tube has 6 built-in lamp tubes, and the power of each lamp tube is 18w. Illumination area 0.3617m 2 Unit illumination area 4.4589m -1 . The ventilation volume is 10L / min. The culture conditions are as follows: both the transgenic type 7120 and the wild type 7120 are cultured in BG-11 medium. BG-11 medium was sterilized at 121°C for 20 minutes. The initial pH value is 8.0, and the culture temperature is 25°C. The wild-type 7120 culture period was 12 days, and the transgenic type culture period was 15 days. Take samples every two days to measure OD 750 . Wild type 7120OD when harvesting algae 750 was 0.428; transgenic type 7120OD 750 is 0.524. See figure 2 . After 12 hours of precipitation, the supernatant was discarded, and the al...

Embodiment example 2

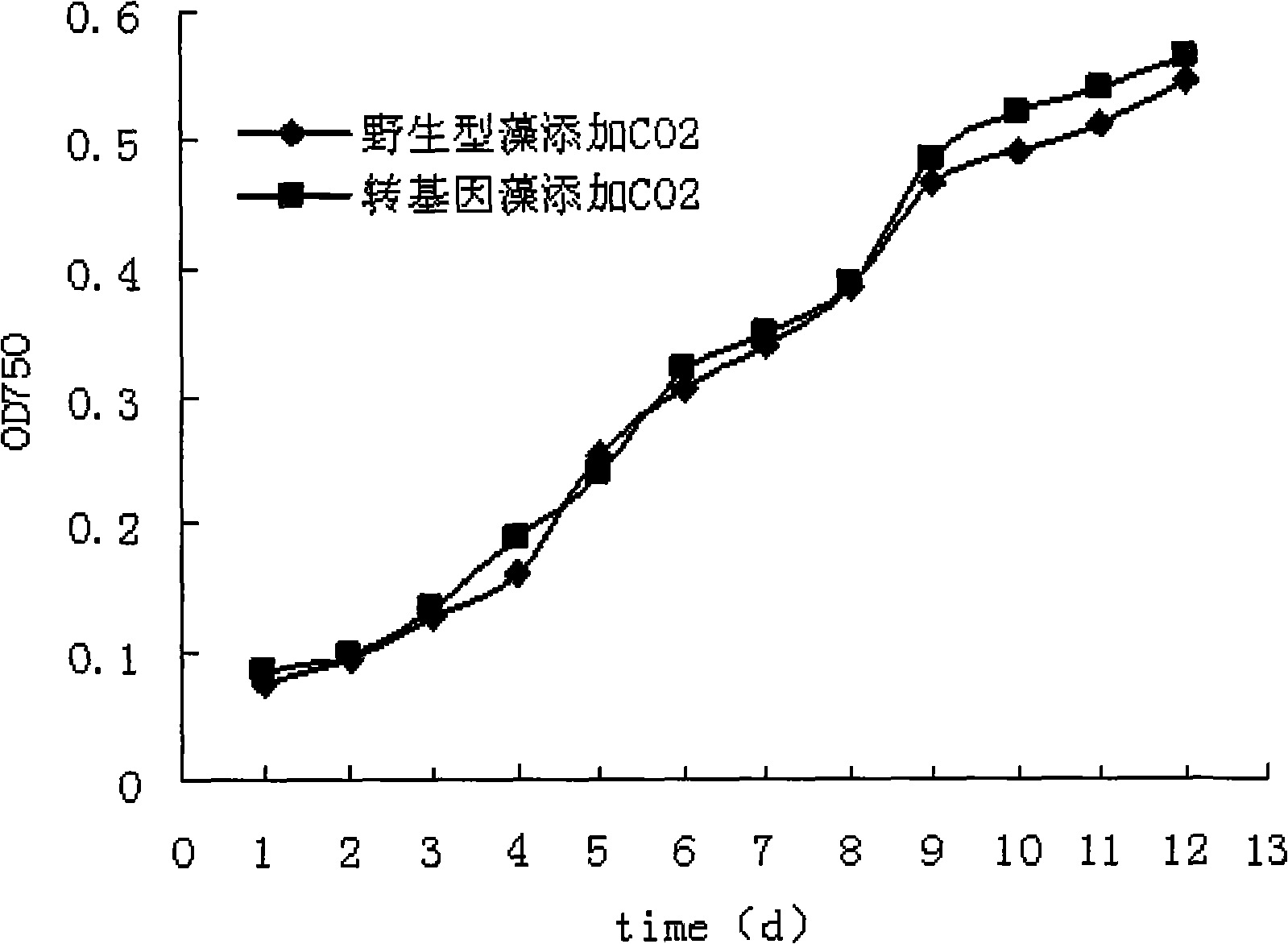

[0025] Improve the closed 100L photoreactor to cultivate cyanobacteria. The main reactor is cylindrical, with a height of 110 cm, a diameter of 35 cm, and a usable volume of 70 L. There are three built-in lamp tubes, and each lamp tube has 6 built-in lamp tubes, and the power of each lamp tube is 18w. Illumination area 0.3617m 2 Unit illumination area 4.4589m -1 . add CO 2 , CO 2 The amount added is controlled at 5% with a flow meter. The ventilation volume is 10L / min. Both the transgenic type 7120 and the wild type 7120 were cultured in BG-11 medium. BG-11 medium was sterilized at 121°C for 20 minutes. The initial pH value is 8.0, and the culture temperature is 28°C. The wild-type 7120 culture period is 12 days, and the transgenic type culture period is 12 days. Daily sampling for OD 750 . Wild type 7120 OD when harvesting algae 750 was 0.545; transgenic type 7120 OD 750 is 0.563. See image 3 . After 12 hours of precipitation, the supernatant was discarded, ...

Embodiment example 3

[0027] Then improve the closed 100L photoreactor to cultivate cyanobacteria. The main reactor is cylindrical, with a height of 110 cm, a diameter of 35 cm, and a usable volume of 70 L. There are three built-in lamp tubes, and each lamp tube has 6 built-in lamp tubes, and the power of each lamp tube is 18w. Illumination area 0.7571m 2 Unit illumination area 9.335m -1 . Both the transgenic type 7120 and the wild type 7120 were cultured in BG-11 medium. BG-11 medium was sterilized at 121°C for 20 minutes. After sterilization, a glucose solution sterilized at 115° C. for 20 minutes was added to the reactor to make the glucose concentration in the reactor 50 mmol / L. The ventilation volume is 10L / min. The initial pH value is 8.0, and the culture temperature is 28°C. The wild-type 7120 culture period was 8 days, and the transgenic type culture period was 8 days. Daily sampling for OD 750 . Wild type 7120 OD when harvesting algae 750 was 0.549; transgenic type 7120 OD 750 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com