Turbocharger cleaning arrangement

A technology of turbo compressors and equipment, applied in mechanical equipment, gas turbine devices, machines/engines, etc., can solve problems such as economic losses in power production, and achieve the effect of easy equipment and economically feasible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

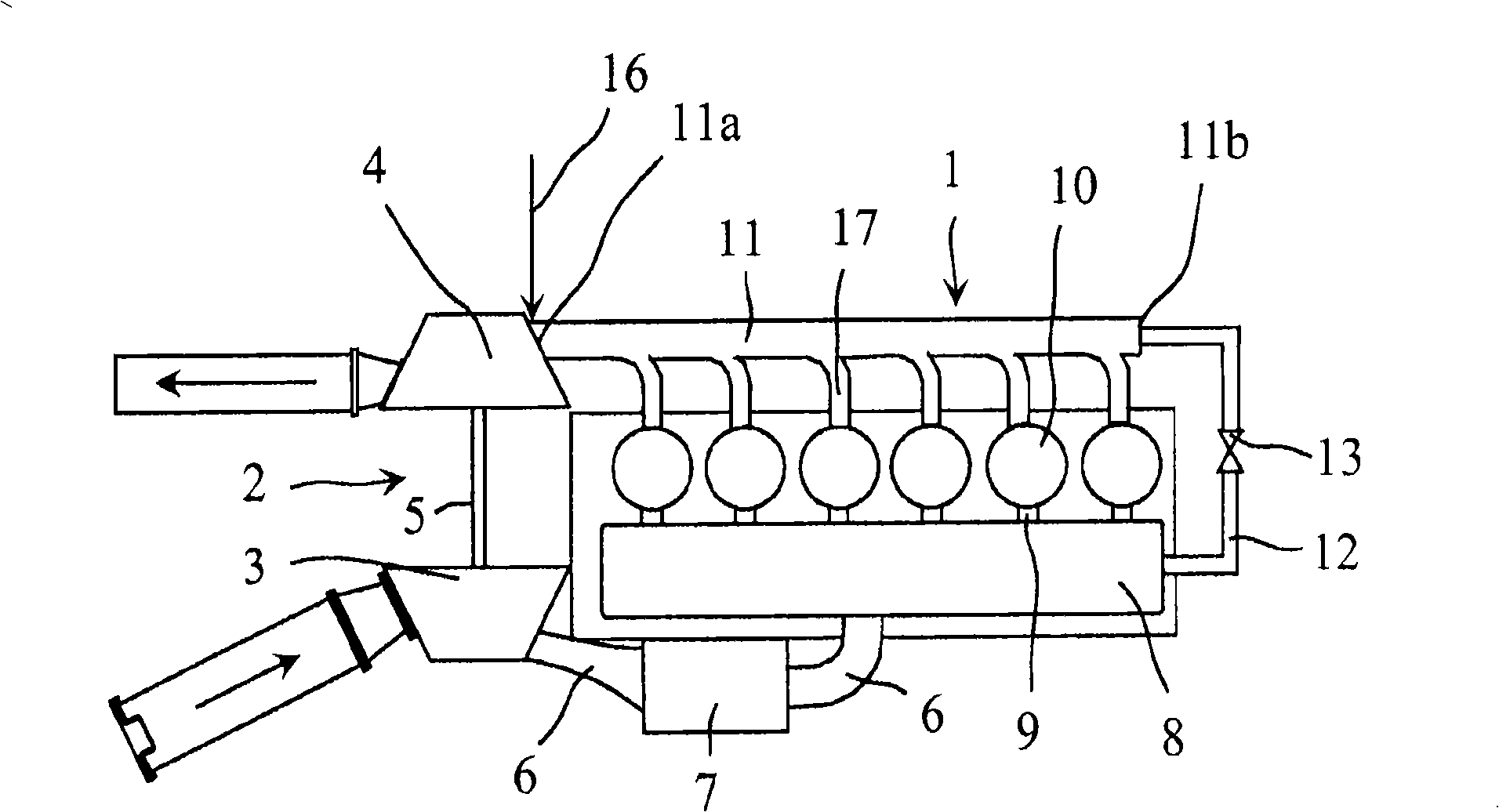

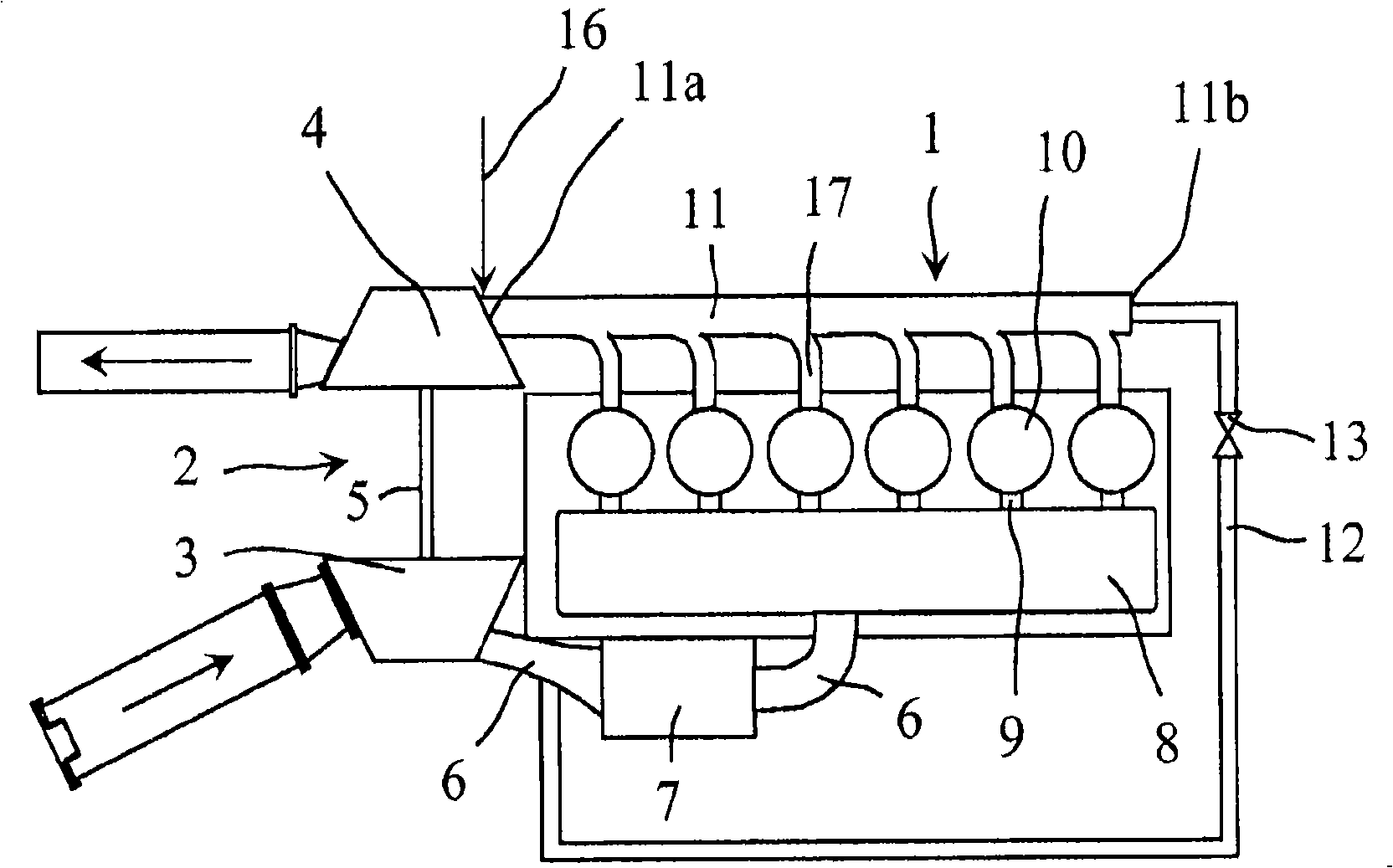

[0019] Figure 1 to Figure 3 A piston engine 1 provided with a turbo compressor 2 is shown. The turbo compressor 2 includes a compressor 3 and a turbine 4 interconnected by a drive shaft 5 . The drive shaft 5 is attached to the casing of the turbocompressor 2 by a bearing system. The task of the compressor 3 is to supply pressurized air to the engine 1 to provide combustion air for fuel. The compressor 3 comprises a rotatable rotor provided with blades to pressurize combustion air for delivery to the engine 1 . The flow space 6 is fitted on the high pressure side of the compressor 3 , ie between the compressor 3 and the combustion space of the engine cylinder 10 , to deliver pressurized combustion air to the cylinder 10 . The flow space 6 is provided with a heat exchanger 7 to cool or heat the combustion air. In addition, the flow space 6 comprises a charge air receiver 8 located behind the heat exchanger 7 in the flow direction of the combustion air. The flow space 6 als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com