A camera marking method based on double 1-dimension drone

A camera coordinate system and camera technology, applied in the field of computer vision, can solve the problems of low calibration accuracy, cumbersome operation, and need for auxiliary equipment, etc., and achieve the effects of improving calibration accuracy, expanding calibration range, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

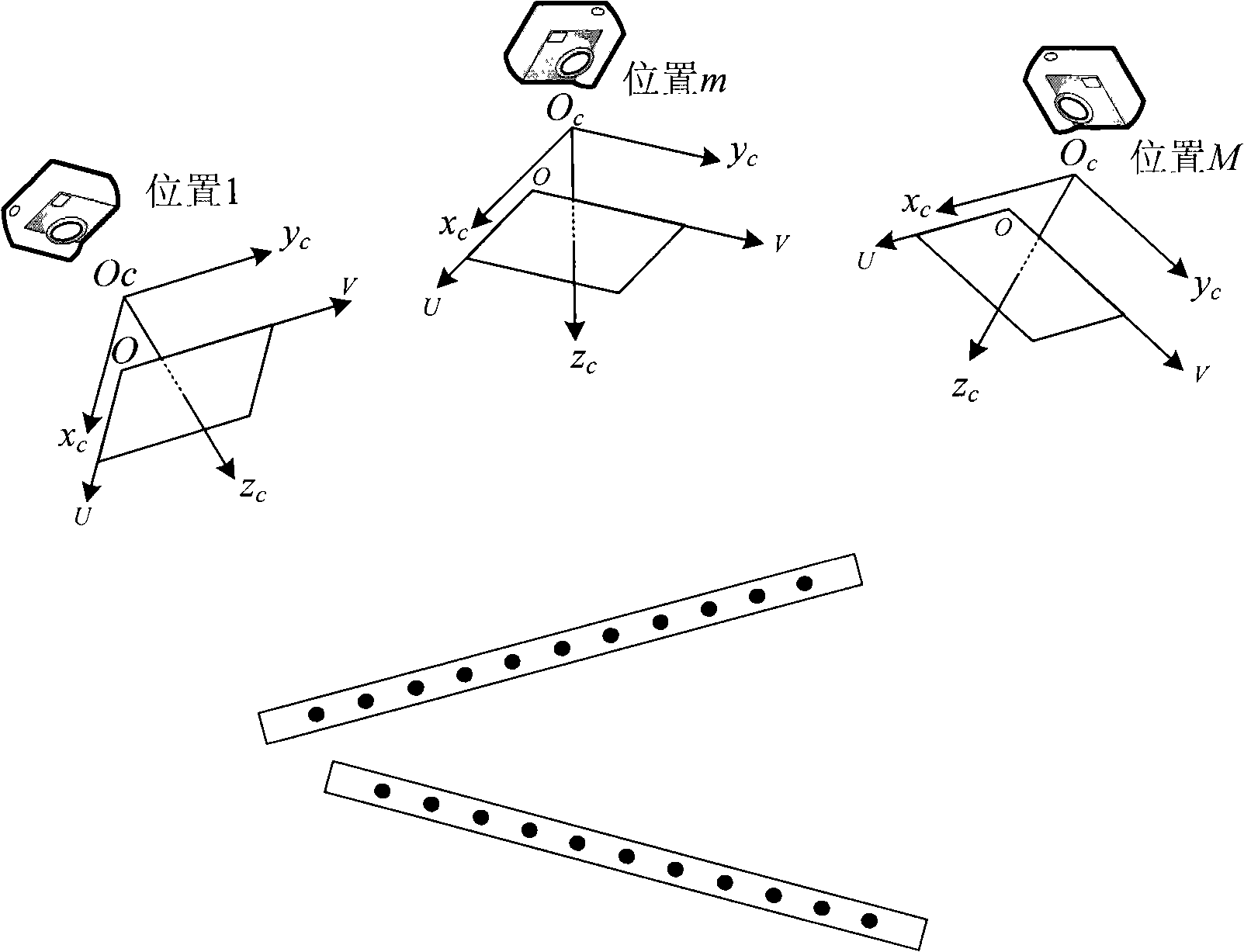

[0028] The basic idea of the present invention is: take two one-dimensional targets as calibration objects, place two one-dimensional targets arbitrarily in the field of view of the camera, take target images from different angles, and only need to extract three or three More than one feature point is used to calibrate the internal and external parameters of the camera.

[0029] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

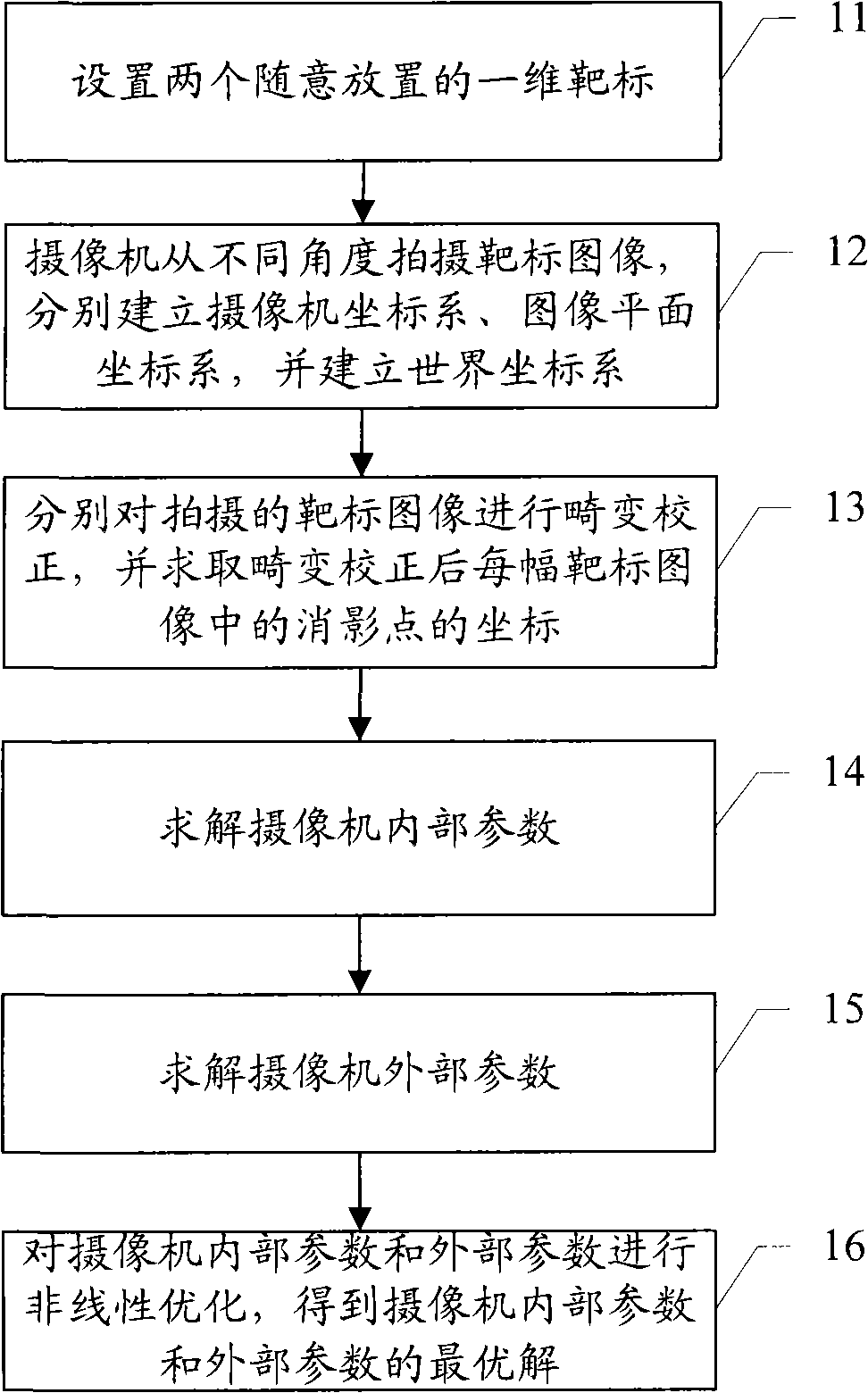

[0030] figure 1 It is a flow chart of the camera calibration method based on the double one-dimensional target of the present invention, such as figure 1 As shown, the camera calibration method based on the double one-dimensional target of the present invention comprises the following steps:

[0031] Step 11: Set up two randomly placed one-dimensional targets.

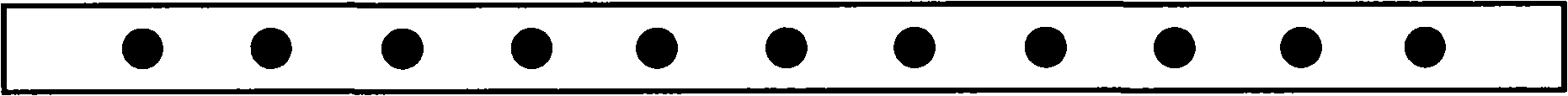

[0032] Here, the one-dimensional target is a linear target whose marker points are collinear, figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com