Semiconductor refrigeration heat converter

A heat exchanger and semiconductor technology, applied in semiconductor devices, semiconductor/solid-state device parts, refrigerators, etc., can solve the problem of large thickness of semiconductor sheets and heat exchangers, low heat dissipation efficiency of semiconductor sheets, and increased width of water dispensers. problems, to achieve the effect of improving flexibility and compactness, strong sealing and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

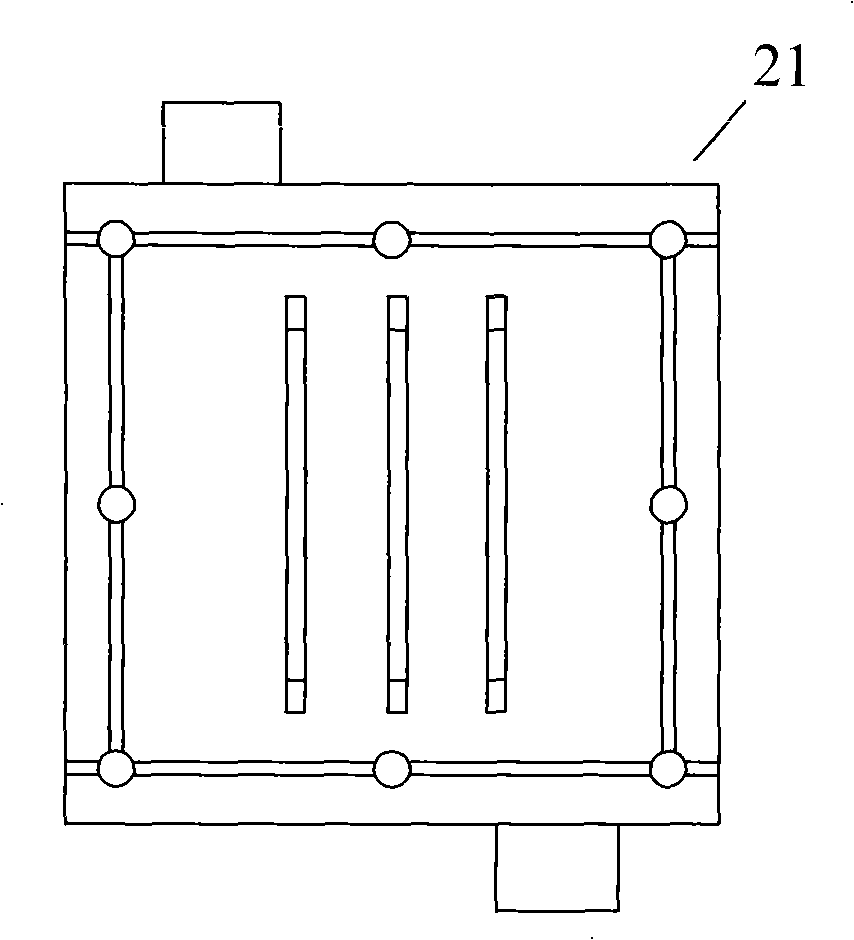

[0021] Such as figure 1 As shown, the semiconductor refrigeration heat exchanger of the present invention includes a semiconductor refrigeration sheet 1 and a heat exchange body 2, and a fluid circulation channel is arranged on the heat exchange body 2, wherein the semiconductor refrigeration sheet 1 is embedded in the heat exchange body 2, and the fluid circulation channel and the heat exchange body 2 The end faces on both sides of the semiconductor refrigeration sheet 1 form independent cold and warm circulation passages 31, 32. A liquid pump 6 is arranged at the intersection of the two passages. The cold flow heat exchange passage 31 is wound around the middle of the medium storage container 4 (such as a water dispenser cooler). On the outer wall, the warm flow heat exchange channel 32 detours through the condenser 5, and a cooling fan is installed on the condenser 5.

[0022] When the present invention is applied to the field of water dispenser, the semiconductor refrigera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com