Polarization type LED luminous tube

An LED light-emitting tube and polarizing technology, which is applied to the semiconductor devices of light-emitting elements, light sources, point light sources, etc., can solve the problems of uneven luminous intensity distribution curve, difficult control, high mold cost, etc. Energy saving effect, low cost, power reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

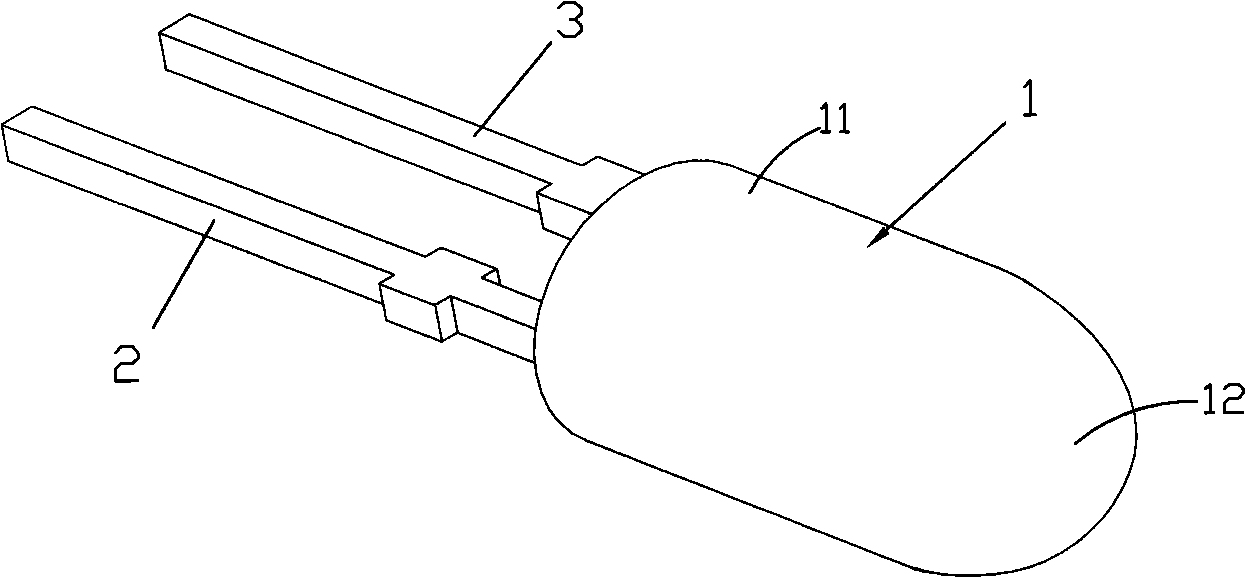

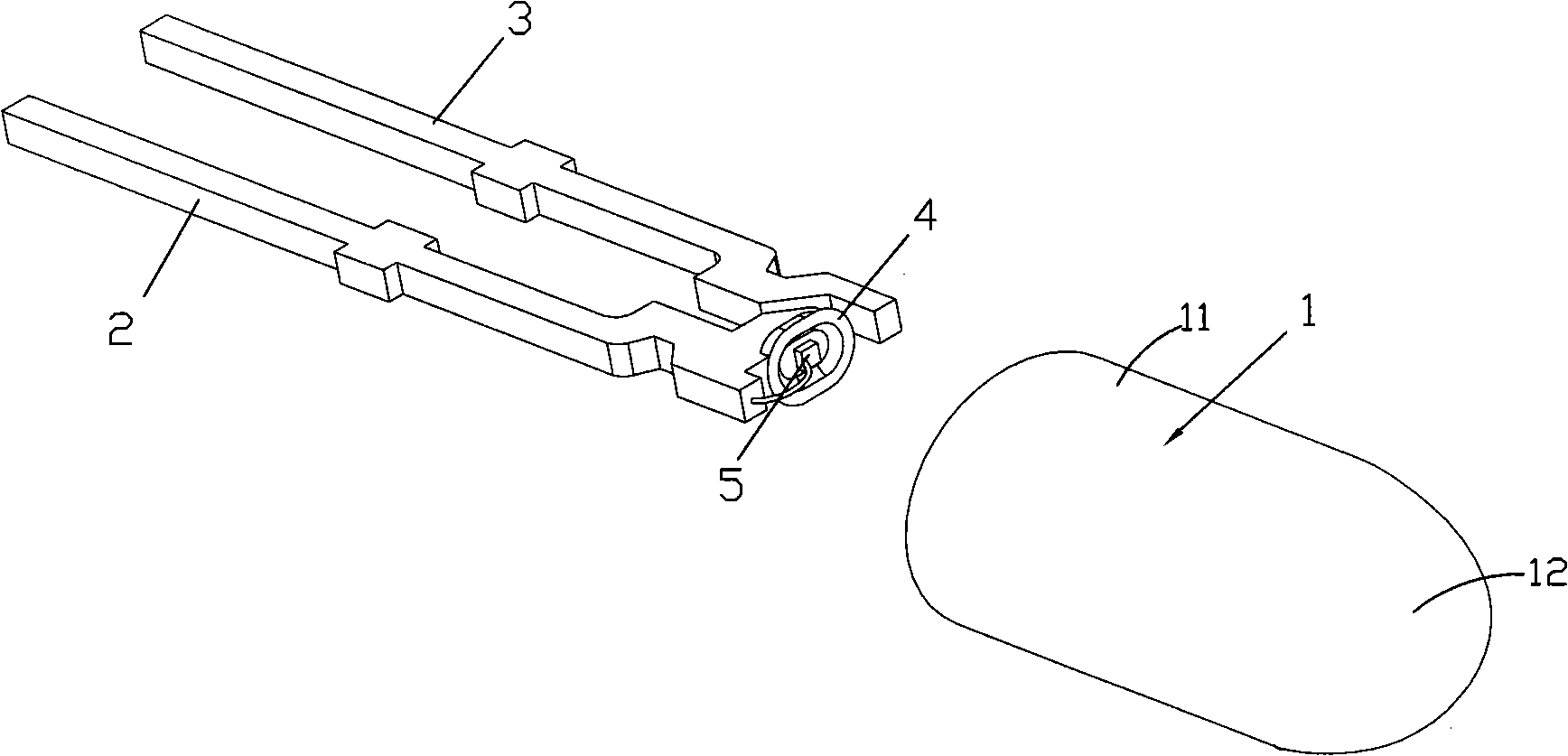

[0022] see figure 1 ~ Fig. 5, an embodiment of the polarized LED luminous tube of the present invention, the LED luminous tube includes two brackets 2, 3 connected by lead wires, a reflective cup 4 placed at the front ends of the brackets 2, 3 and a reflective cup 4 The chip 5 at the bottom, and the encapsulation lens 1 encapsulating the brackets 2, 3 and the reflective cup 4;

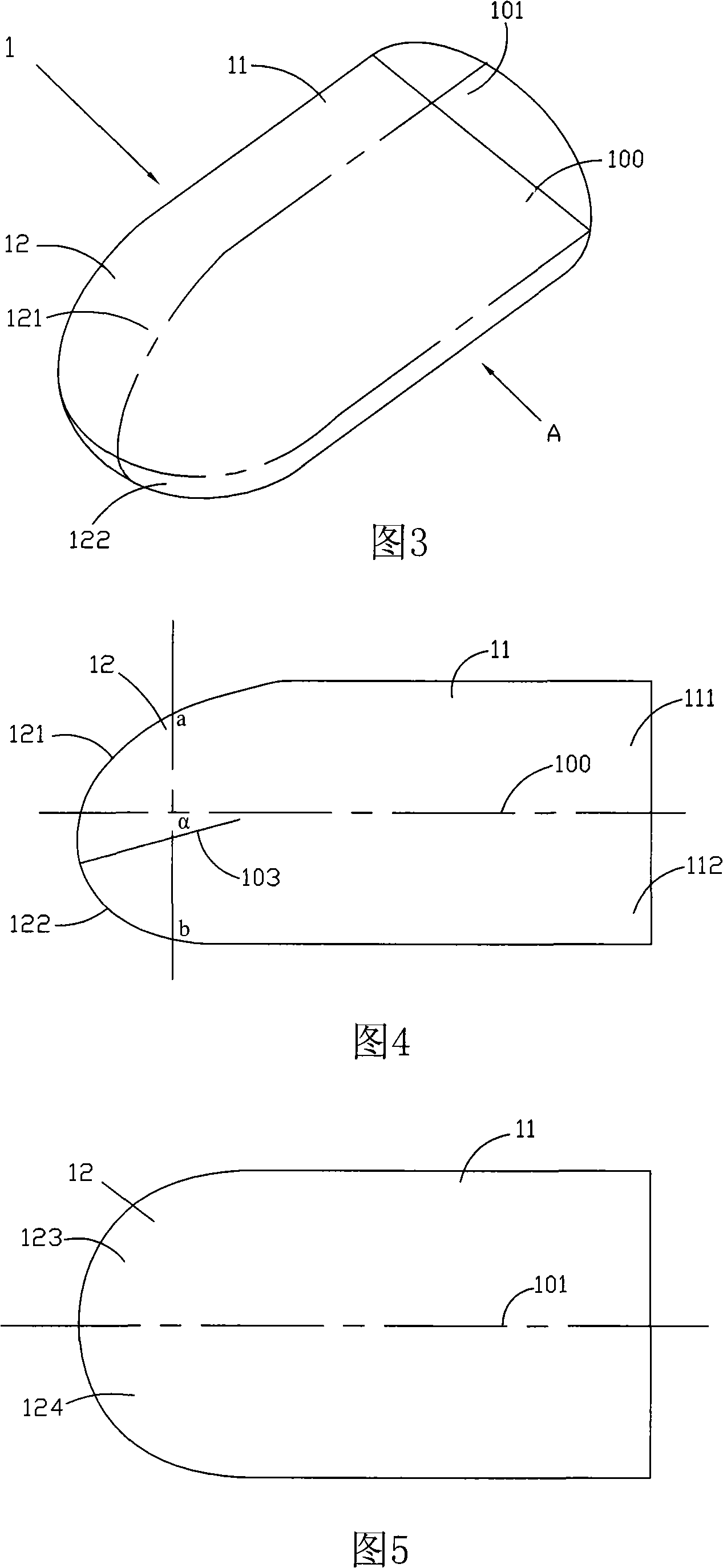

[0023] The encapsulation lens 1 includes a cylindrical portion 11 and a convex portion 12. The plane where the centerlines of the brackets 2 and 3 are located is a horizontal reference plane 100. The two curved surfaces 121, 122 are asymmetrical; the vertical plane 101 where the axial center line of the cylinder part 11 is located is the vertical reference plane 101, and the two left and right curved surfaces 123, 124 of the convex part 12 are symmetrical with the vertical reference plane 101 as the boundary. and, the curvature of a certain point a on the upper curved surface 121 of the convex portion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tilt angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com