Vehicle window glass lifting device and its mounting method

A car window glass and lifting device technology, which is applied in the installation of car window glass lifting devices and the field of car window glass lifting devices, can solve the problems that the limit function cannot be realized, the guide rail is difficult to arrange, and the glass is easy to shake, etc., to achieve compact structure, Space-saving and weight-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

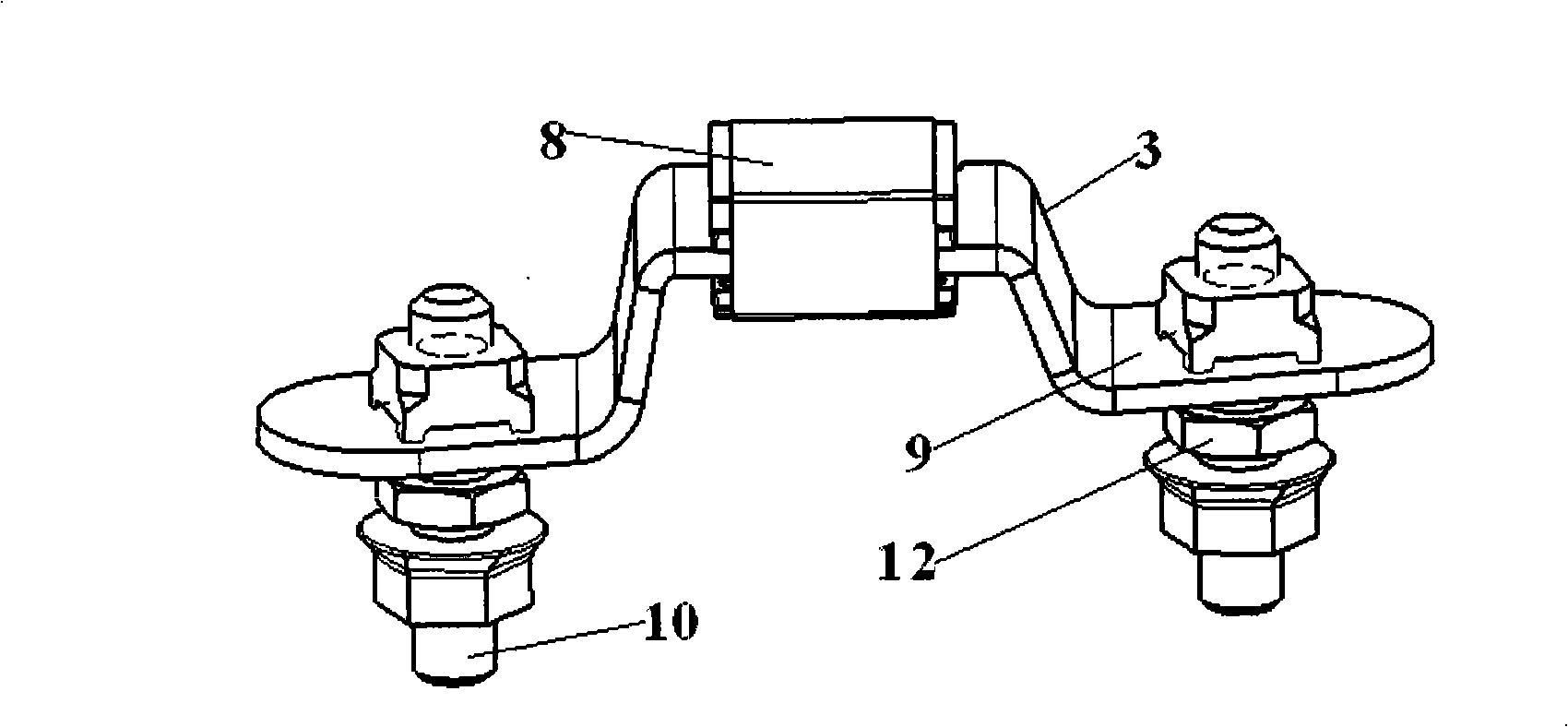

[0057] The purpose of this embodiment is to make the upward limit of the window glass more reliable and stable. Its structure is as follows:

[0058] Such as Figure 6 and Figure 7 As shown, the glass up limit block 1 and the glass up stop block 4 are arranged in pairs, and there are two pairs or more than two pairs.

[0059] Two or more pairs of glass ascending limit block 1 and glass ascending stopper 4 should be separated by a relatively large distance, so that the stability is better.

Embodiment 2

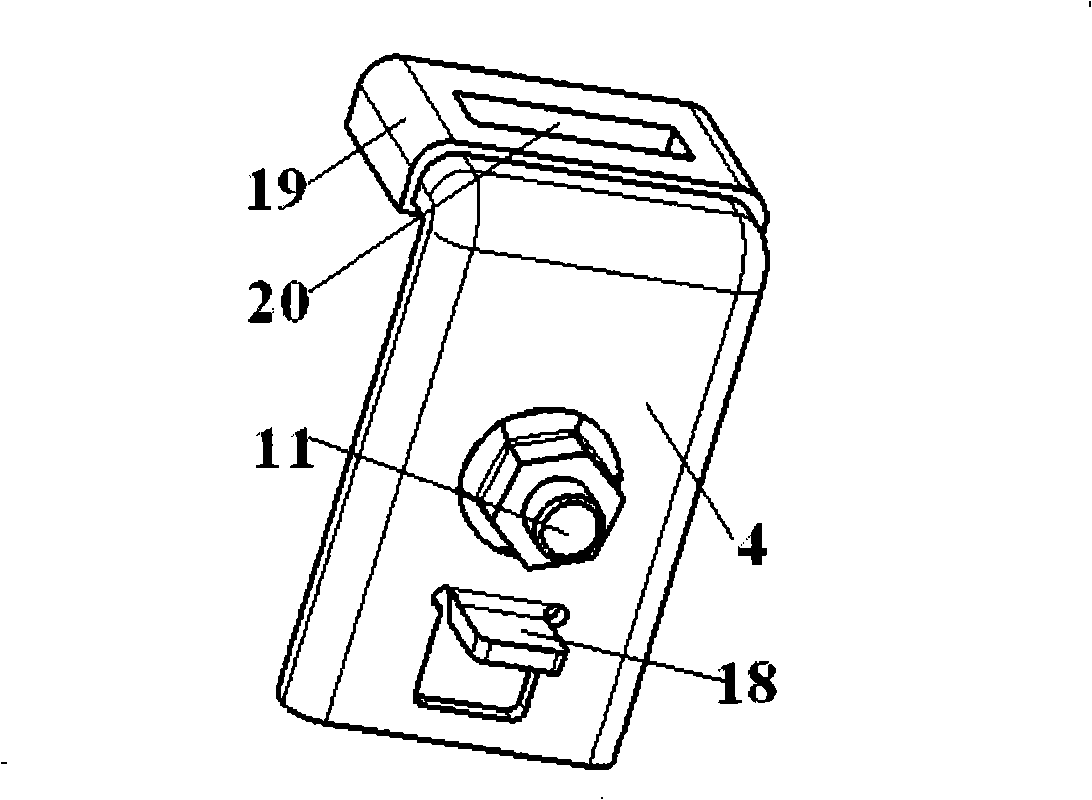

[0061] Similar to Embodiment 1, the purpose of this embodiment is to make the side positioning of the window glass more reliable and stable. Its structure is as follows:

[0062] Such as Figure 5 , Figure 6 and Figure 7 As shown, the glass lateral limit block bracket 3 is two or more than two pieces.

[0063] Two or more glass lateral limit block supports 3 should also be separated by a relatively large distance, so that the stability is better.

Embodiment 3

[0065] The purpose of this embodiment is to prevent the glass rising limit block 1 and the vehicle window glass 2 from falling off. Because the main connection direction of the two is on the plane of the glass, but the force is tangential to the plane, which may cause loosening of the connection. In order to prevent loosening, the following structure is proposed to ensure that the glass rising limit block 1 is in contact with the window Glass 2 will not detach.

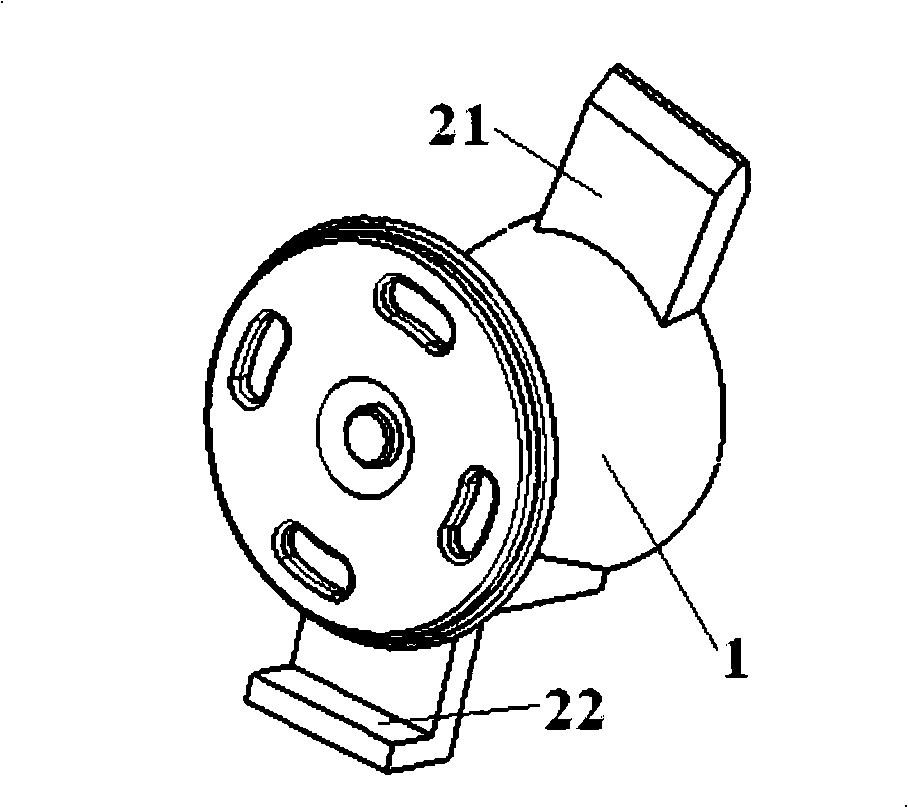

[0066] as shown in the picture figure 1 and Figure 10 As shown, the glass rising limit block 1 is provided with a glass bracket hook 22 bent towards the direction of the window glass 2 at its lower part, and is hooked to the lower edge of the window glass 2 . The force direction of the glass ascending limit block 1 is upward when the position is limited, so the glass bracket hook 22 just plays the role of blocking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com