Multiple placing in turn interleaving flushing pressure variable adsorption technique

A pressure swing adsorption and smooth discharge technology, applied in the field of pressure swing adsorption, can solve the problems of increasing the investment area of the program-controlled valve and the smooth discharge tank equipment, the step time cannot be reduced, and the regeneration effect cannot be achieved, so as to avoid the overall operation. performance, improving low-pressure desorption efficiency, and increasing the effect of regeneration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 110-2-4

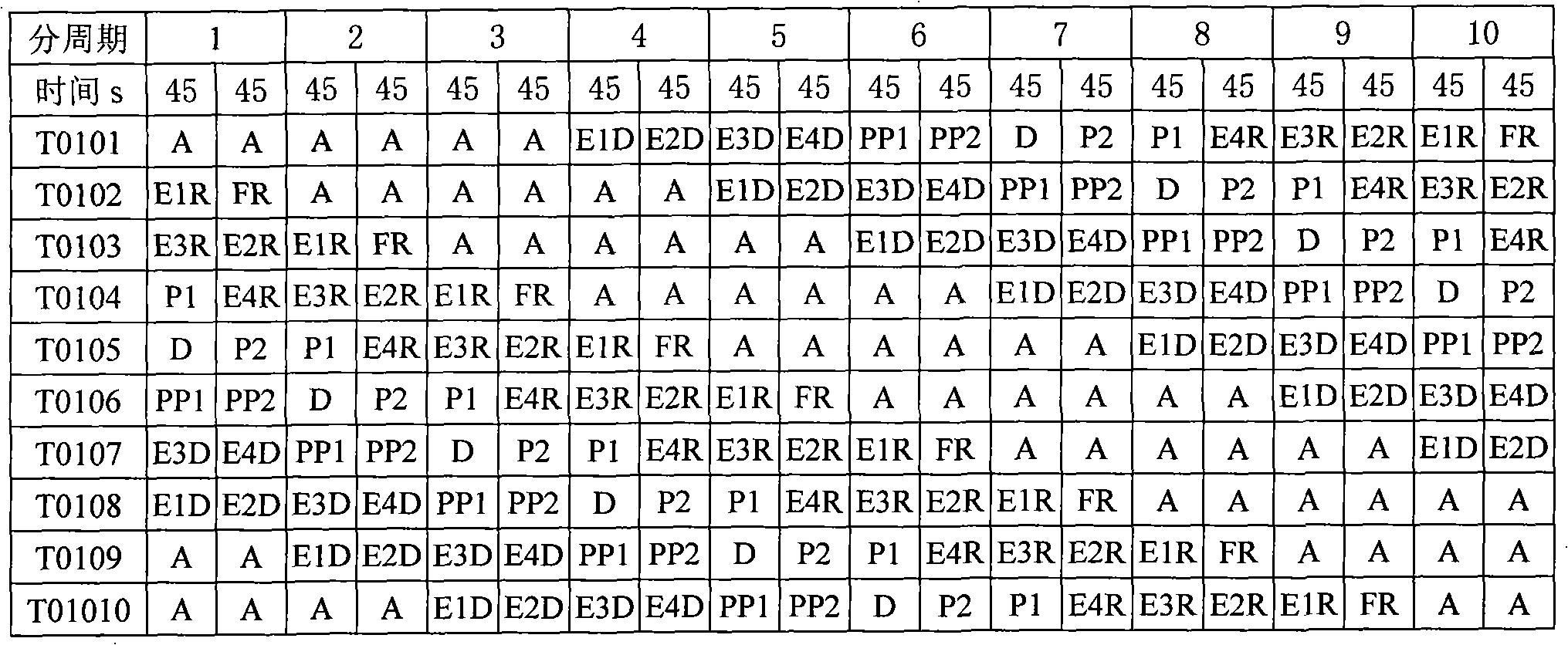

[0042] Embodiment 110-2-4 / P process

[0043] This embodiment is a 10-tower pressure swing adsorption method for separating and recovering hydrogen from the shift gas. The operating pressure is 2.4MPa, the temperature is 40°C, the hydrogen content in the raw material gas to be processed is 70%, and the product hydrogen requires H 2 ≥99.9%.

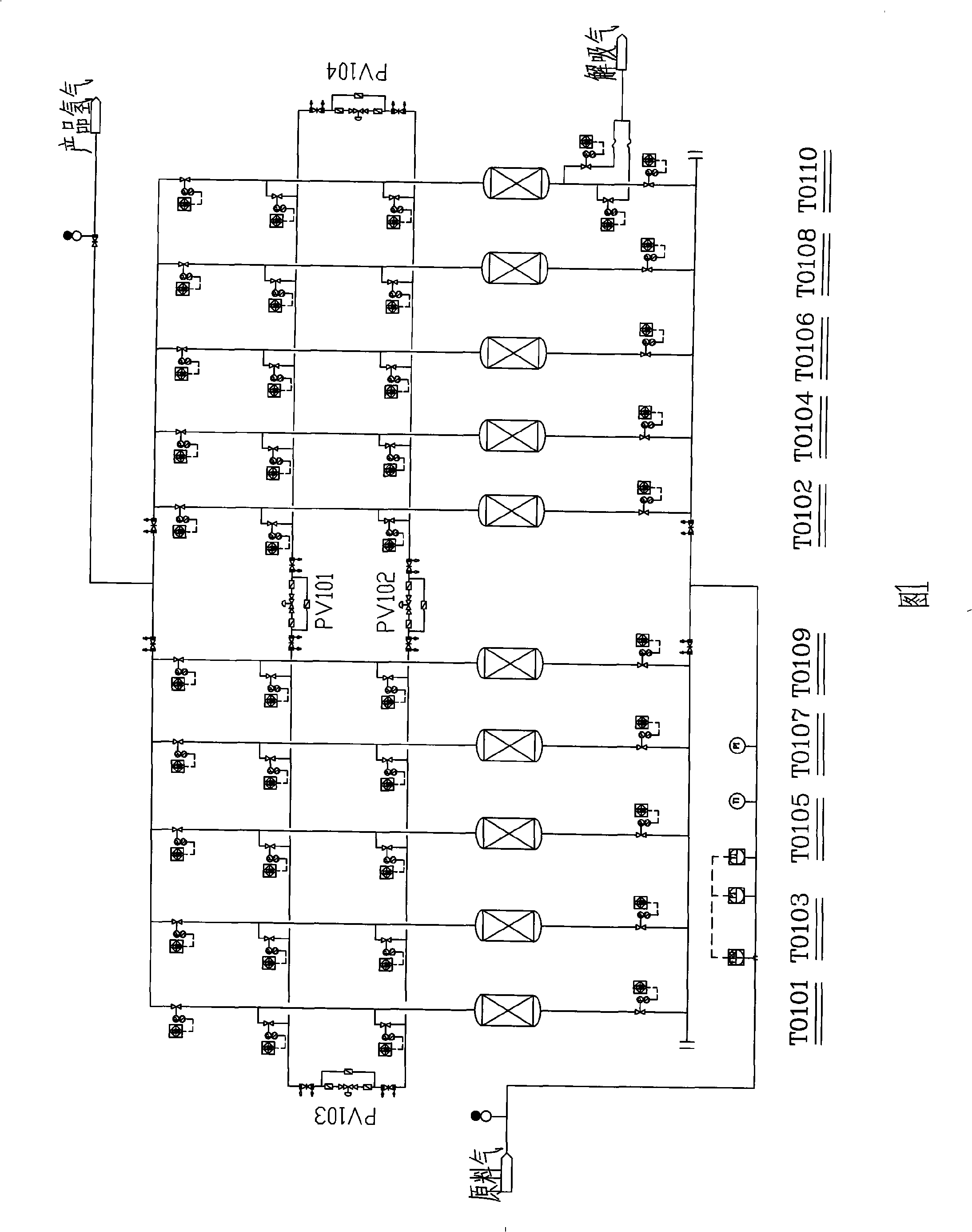

[0044] As shown in Figure 1, the pressure swing adsorption device of this embodiment is divided into two series, wherein T0101, T0103, T0105, T0107, T0109 adsorption towers form a single series, and T0102, T0104, T0106, T0108, T0110 form a double series; One regulating valve PV101 and PV102 are respectively set up for the single and double series, and two regulating valves PV103 and PV104 are set between the two rows of parallel flushing program-controlled valves; manual cut-off valves are set before and after the two rows of parallel flushing regulating valves of the single and double series; Two on / off two-position program-controlled val...

Embodiment 212-3-5

[0054] Embodiment 212-3-5 / P process

[0055] This embodiment is a 12-tower pressure swing adsorption method for separating and recovering hydrogen from neutral gas. The operating pressure is 2.7MPa, the temperature is 40°C, the hydrogen content in the raw material gas to be processed is 70%, and the product hydrogen requires H 2 ≥99.9%.

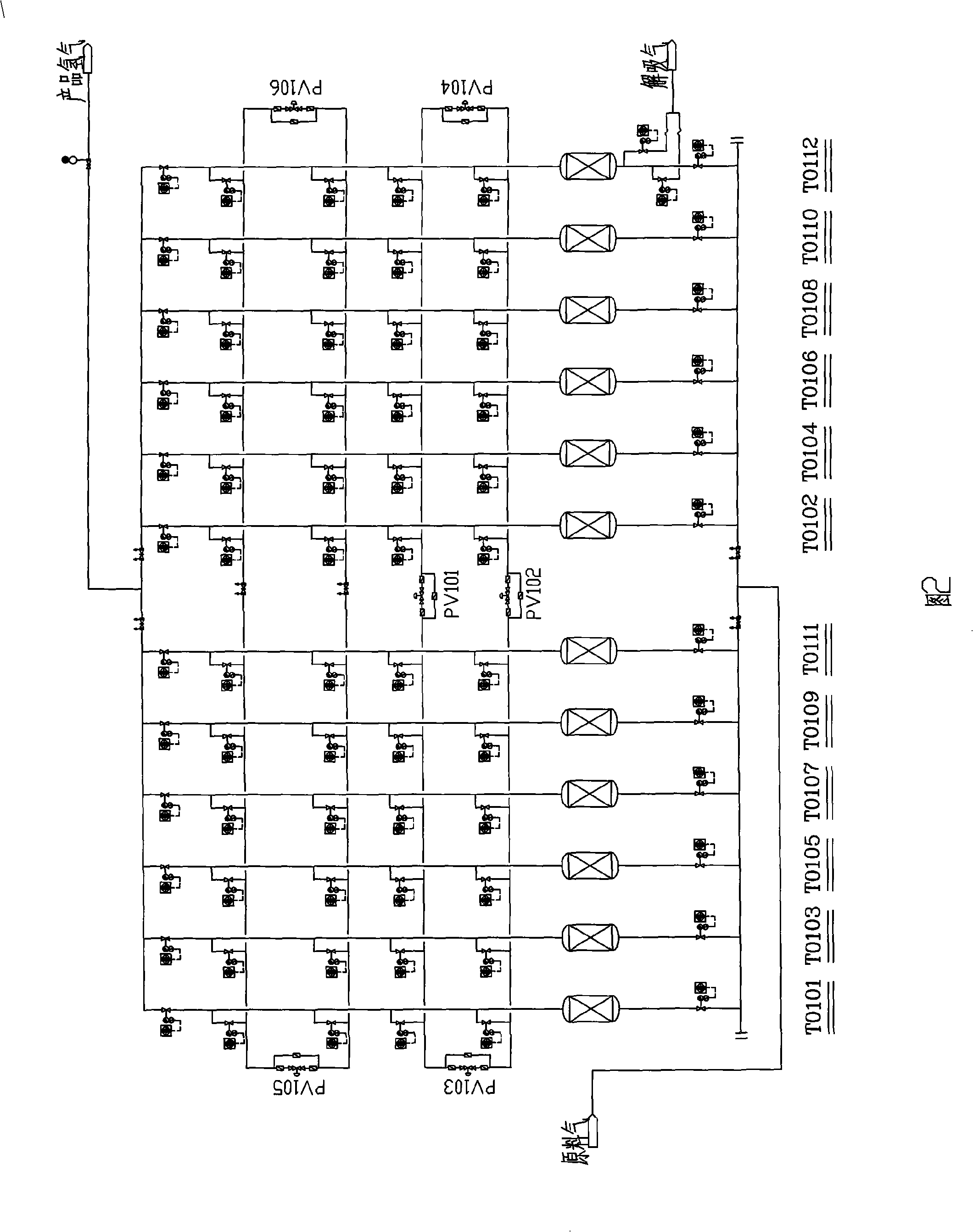

[0056] The pressure swing adsorption device of this embodiment is divided into two series, wherein T0101, T0103, T0105, T0107, T0109, T0111 adsorption towers form a single series, and T0102, T0104, T0106, T0108, T0110, T0112 adsorption towers form a double series; For the single and double series, one control valve PV101 and PV102 are respectively set up, and two control valves PV103 and PV104 are set between the two rows of flushing program-controlled valves; two on / off two-position valves are installed on the outlet pipeline at the top of each adsorption tower. The program-controlled valve is used as the discharge outlet valve and the flus...

Embodiment 312-2-5

[0061] Embodiment 312-2-5 / P process

[0062] This embodiment is a 12-tower pressure swing adsorption method for separating and recovering hydrogen from neutral gas. The operating pressure is 2.7MPa, the temperature is 40°C, the hydrogen content in the raw material gas to be processed is 70%, and the product hydrogen requires H 2 ≥99.9%.

[0063] The pressure swing adsorption device of this embodiment is divided into two series, wherein T0101, T0103, T0105, T0107, T0109, T0111 adsorption towers form a single series, and T0102, T0104, T0106, T0108, T0110, T0112 adsorption towers form a double series; For the single and double series, one control valve PV101 and PV102 are respectively set up, and two control valves PV103 and PV104 are set between the two rows of flushing program-controlled valves; two on / off two-position valves are installed on the outlet pipeline at the top of each adsorption tower. The program-controlled valve is used as the discharge outlet valve and the flus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com