Carrier strip system and method for different diameter fasteners

A technology for bracket strips and fasteners, applied in the direction of threaded fasteners, connecting components, nails, etc., can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

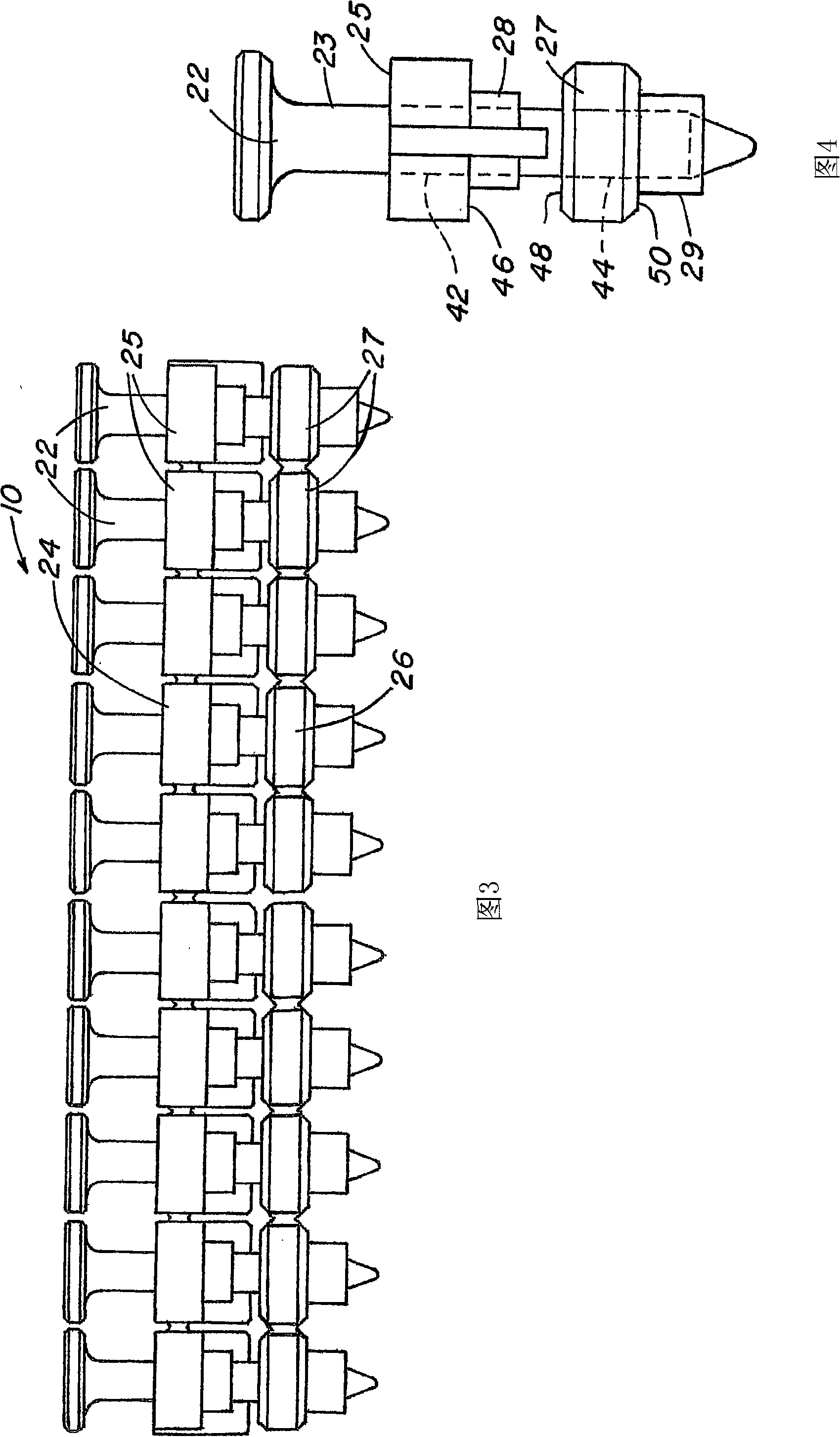

[0010] With regard to the aforementioned shortcomings in the prior art, the presently disclosed design allows fasteners of different diameters to run in the same tray of the installation tool. For this application to work, the outside diameter of the fastener carrier band must remain the same for different fastener diameters and still hold the fastener securely in place. Also, since the installation tool tray uses the diameter surface of the fastener as an additional guide surface, in the case of smaller diameter fasteners used in the same installation tool tray, when using the smaller diameter fastener , accommodation must be made for the outer diameter guide function of larger diameter fasteners.

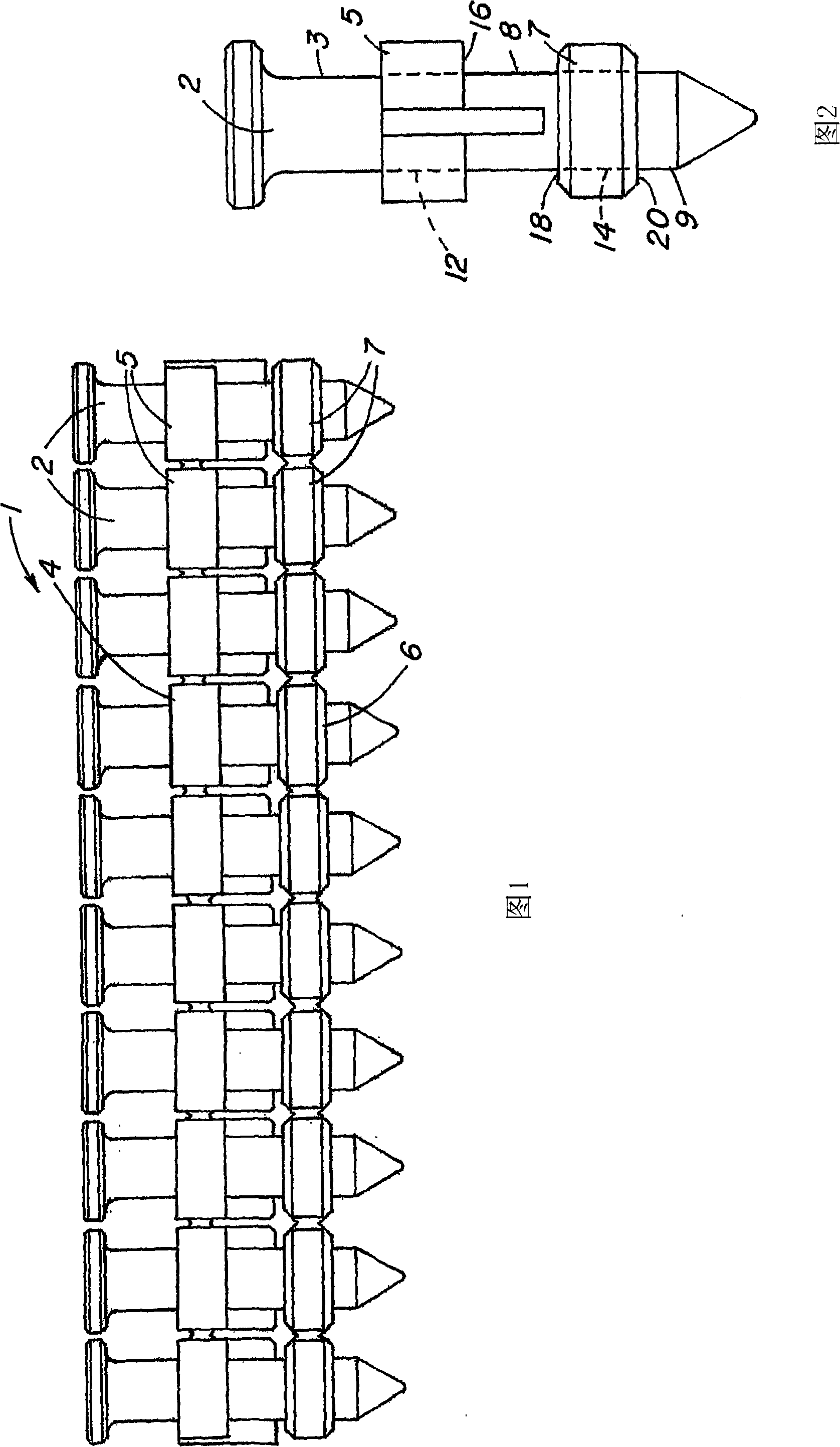

[0011] Referring to Fig. 1, the illustrated large-diameter bracket band assembly 1 includes: a large-diameter fastener 2, a large-diameter head-end connecting band 4 (break-free strip) composed of several head-end parts 5, and a number of tip parts 7 constitutes a large-diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com