Method and apparatus for assembling die on electronic substrate

A substrate and die technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of reducing the degree of plastic deformation strain, reducing the life cycle of the die package, etc., to achieve the effect of reducing the life cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Referring now to the drawings, and in particular to Figures 1-18b, there are shown exemplary embodiments of methods and structures in accordance with the present invention.

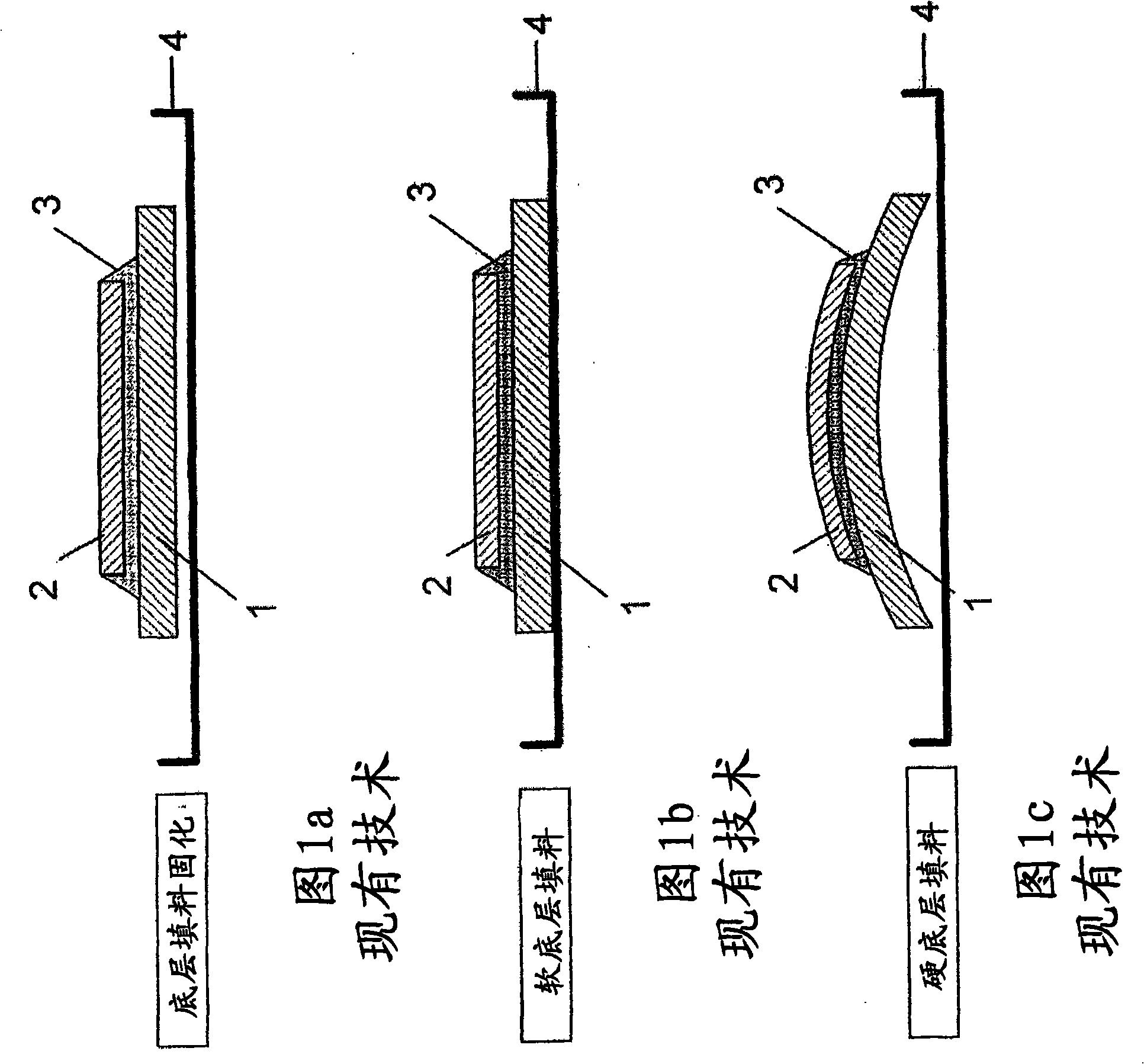

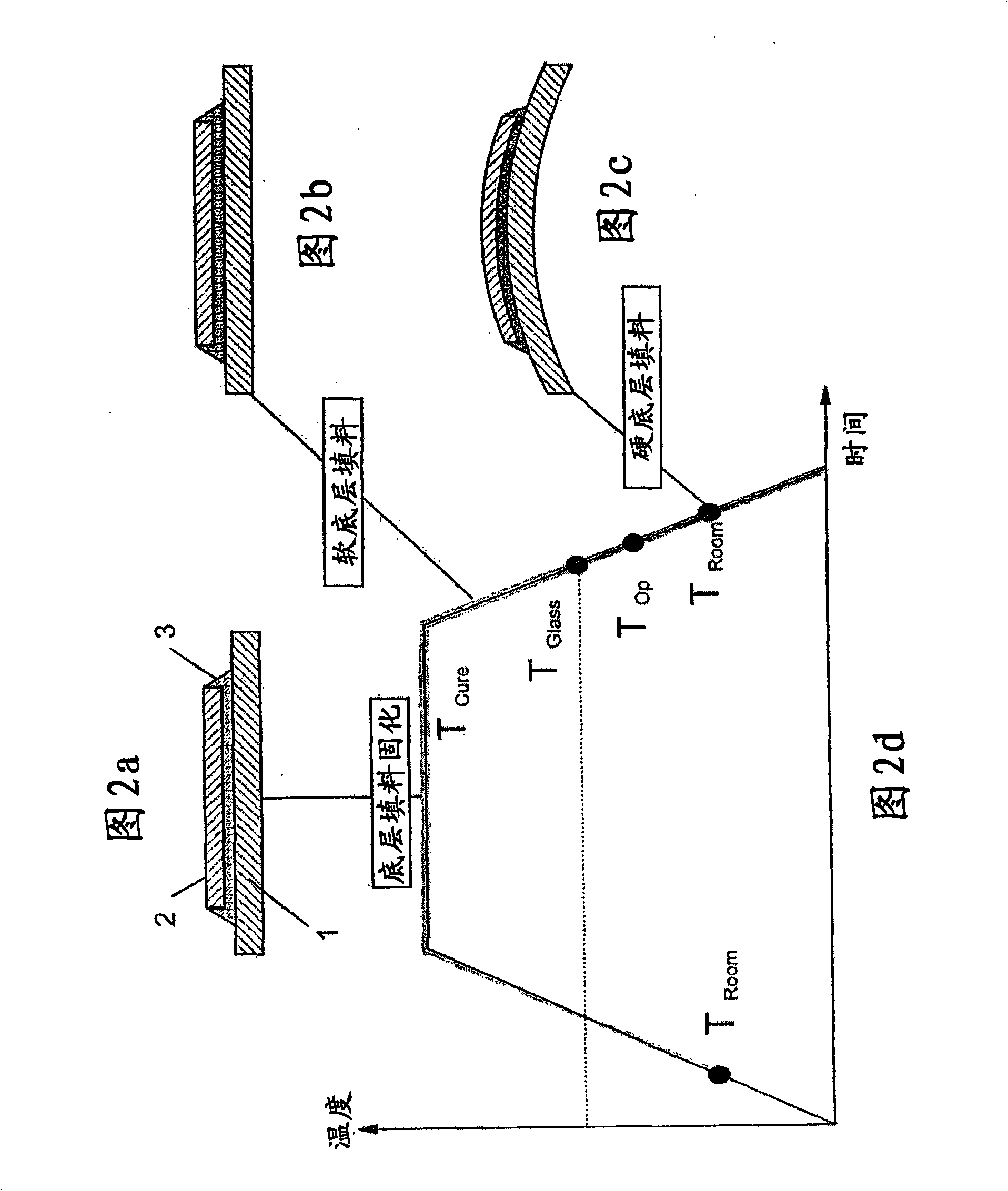

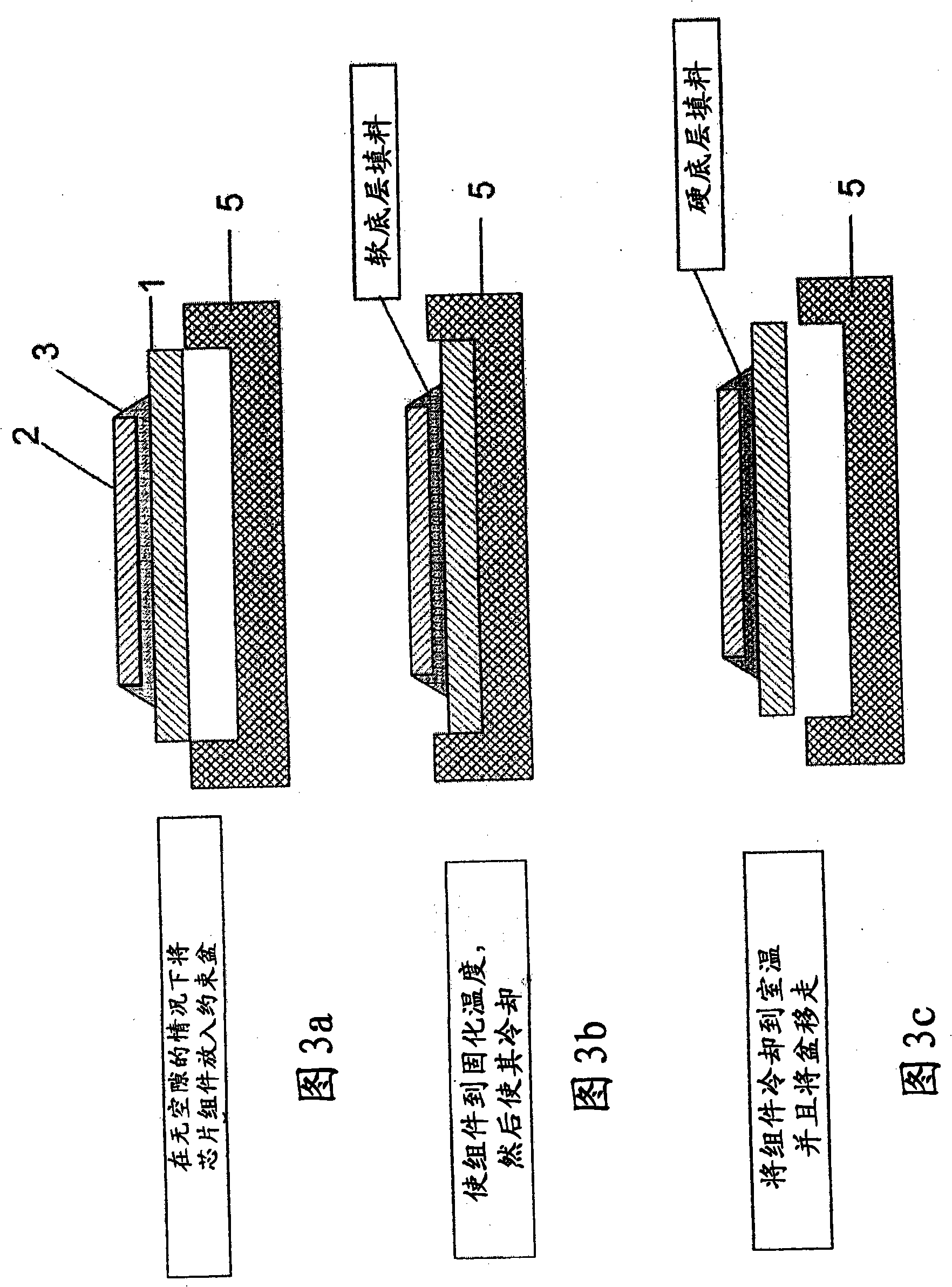

[0040] Figures 1a-1c illustrate the three stages of a die 2 / substrate 1 / underfill 3 assembly during a curing cycle. The substrate 1 and die (chip) 2 that have been bonded by the reflow process are injected with an underfill 3 and placed in a tray 4 .

[0041] Figure 1 a shows the underfill 3 being soft at the start of the curing process, during which the underfill 3 hardens thermally as it cures. Underfill 3 at its glass transition temperature (T glass ) above are generally soft. As the glass transition temperature is crossed, as shown in Figure 1b, at the glass transition temperature (T glass ), the hardened underfill 3 essentially locks the substrate 1 and the silicon (die 2) in their freely expanded state.

[0042] As the package is cooled, the substrate 1 (eg, with a 5×CTE) is more than fiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com