Tester for tartness degree of tool cutting edge

A sharpness and tester technology, which is applied in the field of tool edge sharpness testers to achieve objective test results, accurate data and good reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

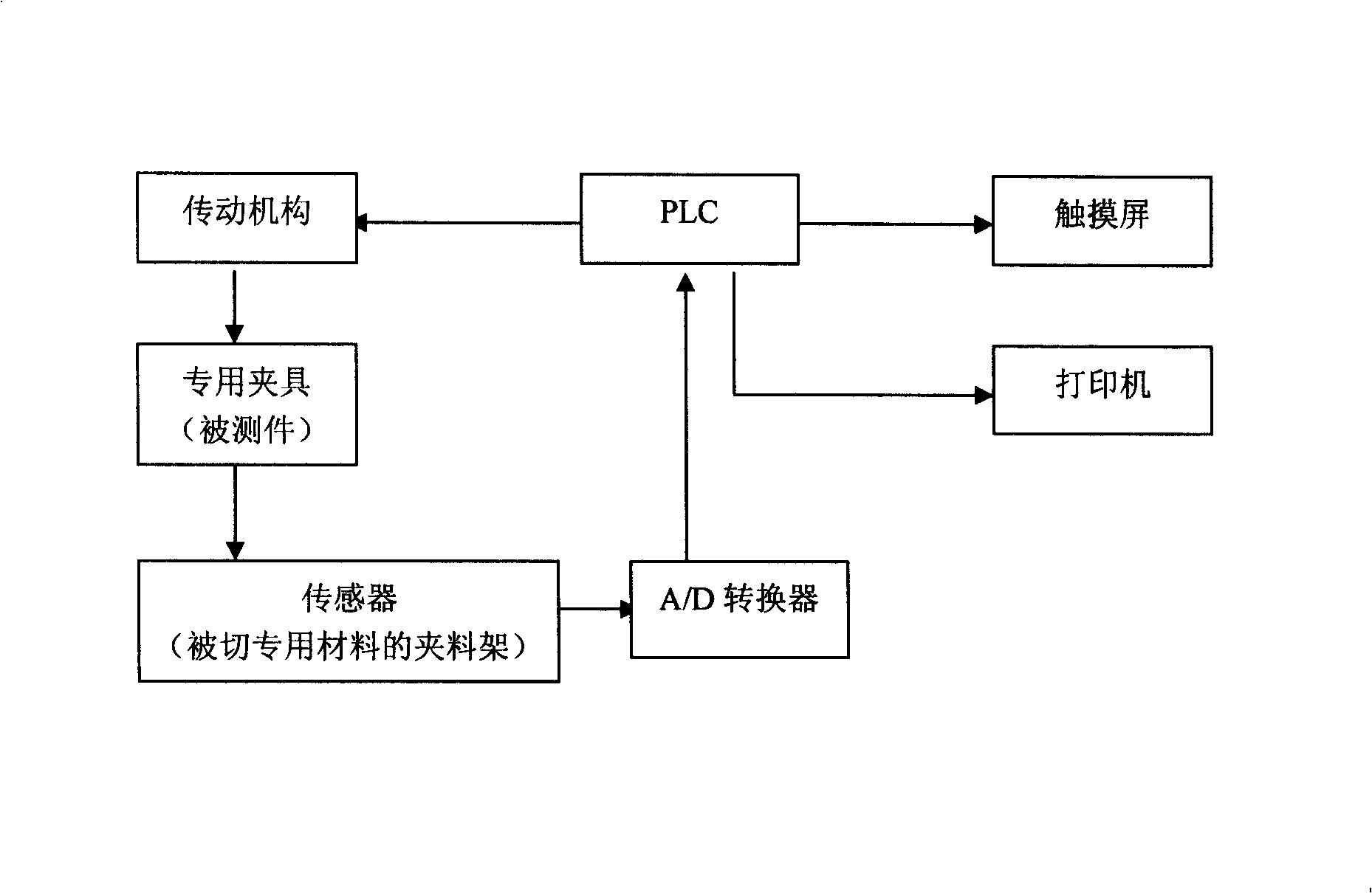

[0015] like figure 1 As shown, the invention discloses a tool edge sharpness tester. It includes PLC, input and output devices, transmission mechanism, special fixtures, special materials to be cut with sensors, and A / D converter, among which: the PLC is the core component, which is used to accept commands input from the input device to control the transmission The mechanism and the special fixture perform the shearing action, then accept the A / D converted signal from the sensor for processing, and output the test value through the output device.

[0016] The working principle of the device of the present invention is: the transmission mechanism is driven by a stepping motor controlled by PLC, so that the special fixture equipped with the tool to be tested moves up and down to complete the cutting process of the special material installed on the sensor. In the cutting of special materials, the sensor is subjected to the force of the cutting edge, and the sensor generates a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com