High-strength prestressed concrete pipe pile construction method

A technology of concrete pipe piles and construction methods, which can be applied to sheet pile walls, foundation structure engineering, buildings, etc., and can solve the problems of pipe piles with high safety requirements for buckling resistance and pullout resistance, heavy bearing weight, and high-rise buildings. Construction safety, stability, reliability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

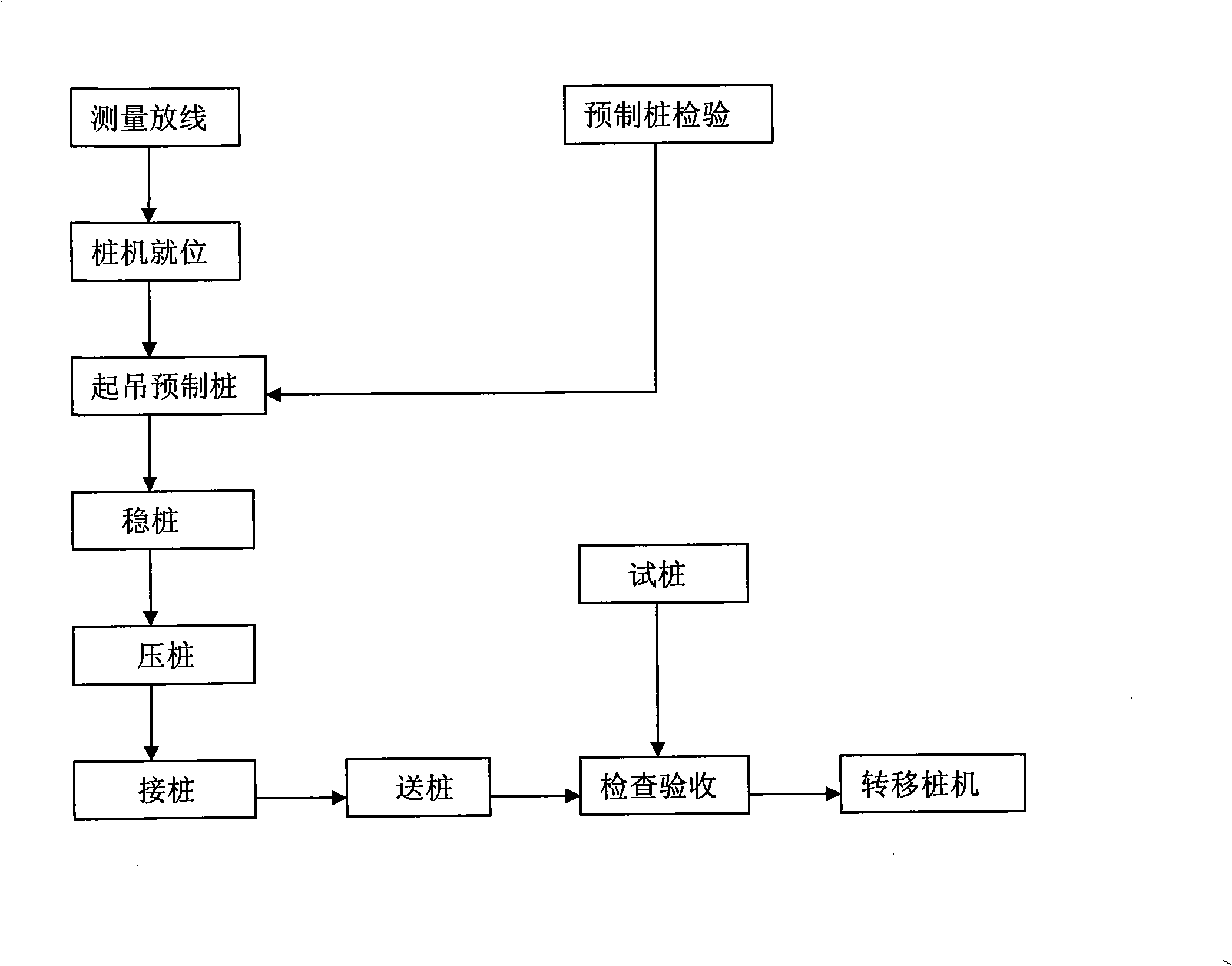

[0005] The specific implementation of the present invention will be described in detail below in conjunction with the construction flow chart.

[0006] Given by flow chart, the present invention is realized by the following steps:

[0007] 1. Surveying and setting out: Set up control pile pre-leveling points near the piling construction area, not less than 2. The position is based on the principle of not being affected by piling (outside 40m from the operation site), and the axis control should be set at a distance from the outer wall pile. 5-10m to control the axis and elevation of the pile;

[0008] 2. The pile driver is in place: move the static pile driver to the top of the pile according to the piling sequence, and align it with the pile location, adjust the static pile driver to a level and stable position, and ensure that no tilting and movement occur during construction;

[0009] 3. Lifting prefabricated piles: the concrete strength of precast concrete piles can only ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Severe | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com