Double-head herringbone thread sewing machine and method for making same

A sewing machine and sewing machine head technology, applied in the field of sewing, can solve the problems of lack of competitiveness and low production efficiency, and achieve the effect of solving high labor costs, improving production efficiency and improving competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

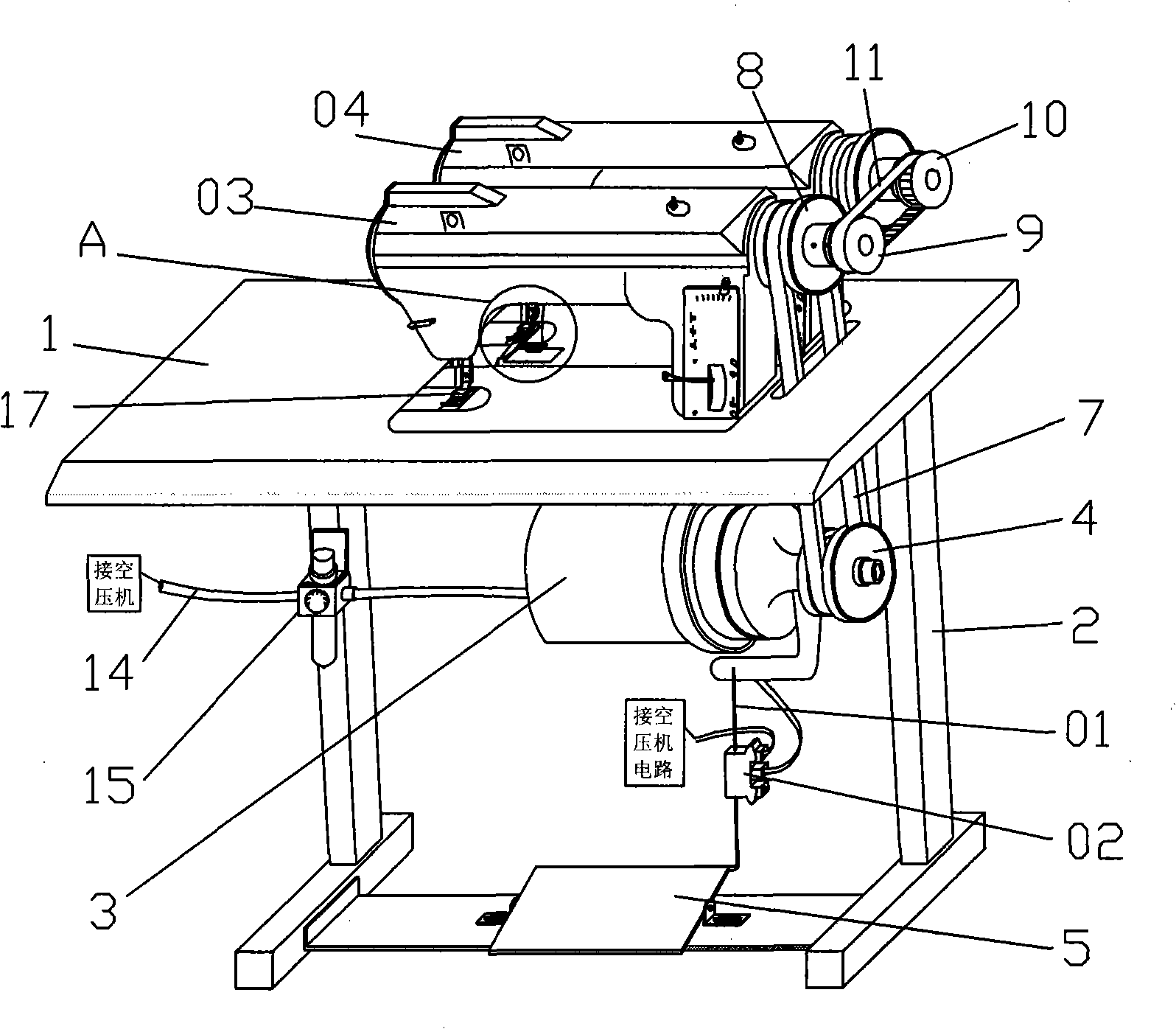

[0018] figure 1 Shown the basic structure of preferred embodiment of the present invention, described double-head herringbone sewing machine, comprises frame 2, is located at the panel 1 of this frame top, is located at the pedal 5 of frame bottom and its Connecting rod 15, the motor 3 that is located at the bottom of this panel, the driving pulley 4 that is located on the motor output shaft, the foot switch of the starting motor that is connected with the connecting rod 15 of pedal. The panel is provided with two herringbone sewing heads in parallel, wherein the first herringbone sewing head 03 is provided with a driven pulley 8 and a first synchronous pulley 9 in turn on the rotating shaft, and the second herringbone sewing head 04 The rotating shaft is provided with the second synchronous pulley 10 that cooperates with the first synchronous pulley 9, and the first and second synchronous pulleys are connected by a synchronous belt 11, and the driven belt of the first herring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com