Portable electric tool with braking device

A technology of hand-held machine tools and braking devices, which is applied in the direction of manufacturing tools, electromechanical devices, electric components, etc., and can solve problems such as increasing expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

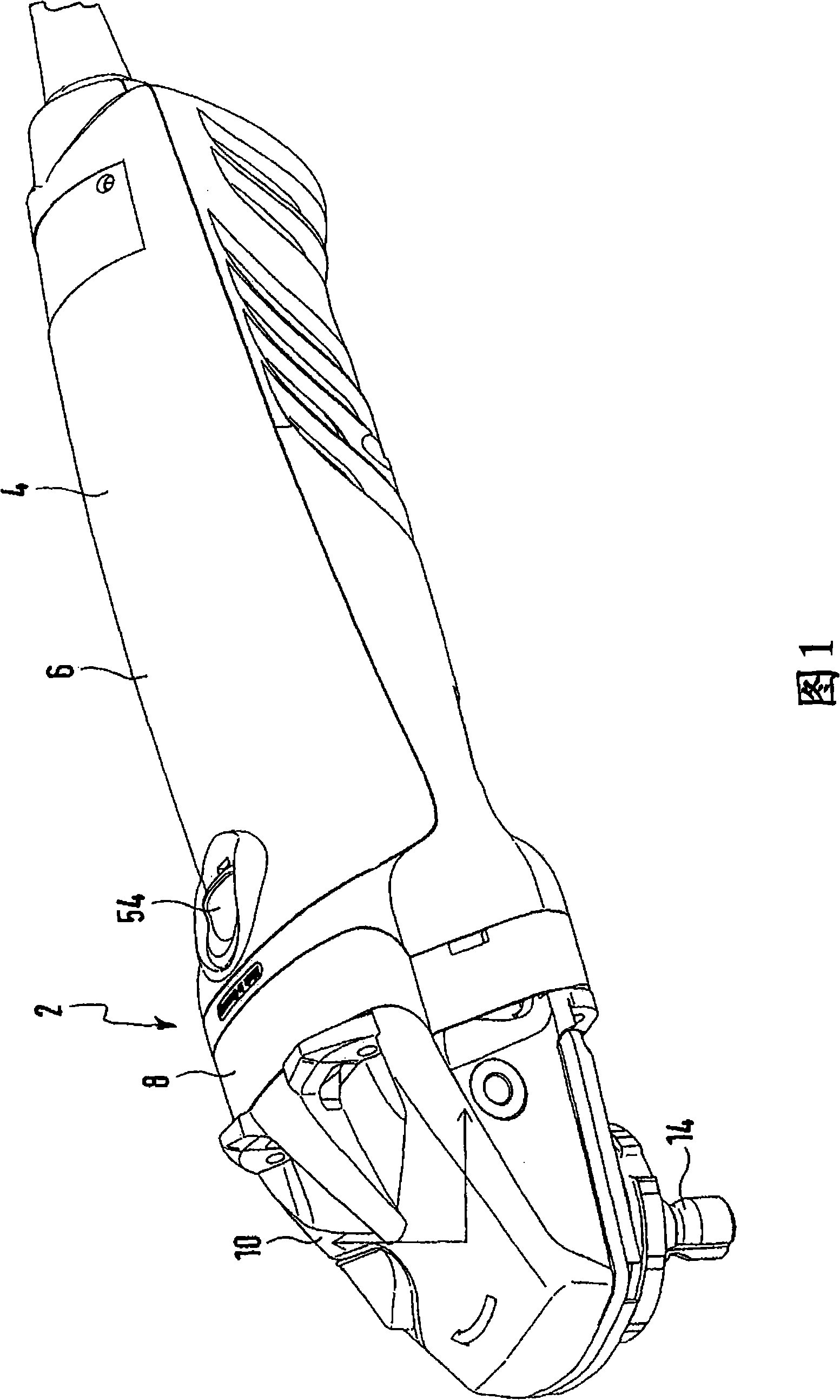

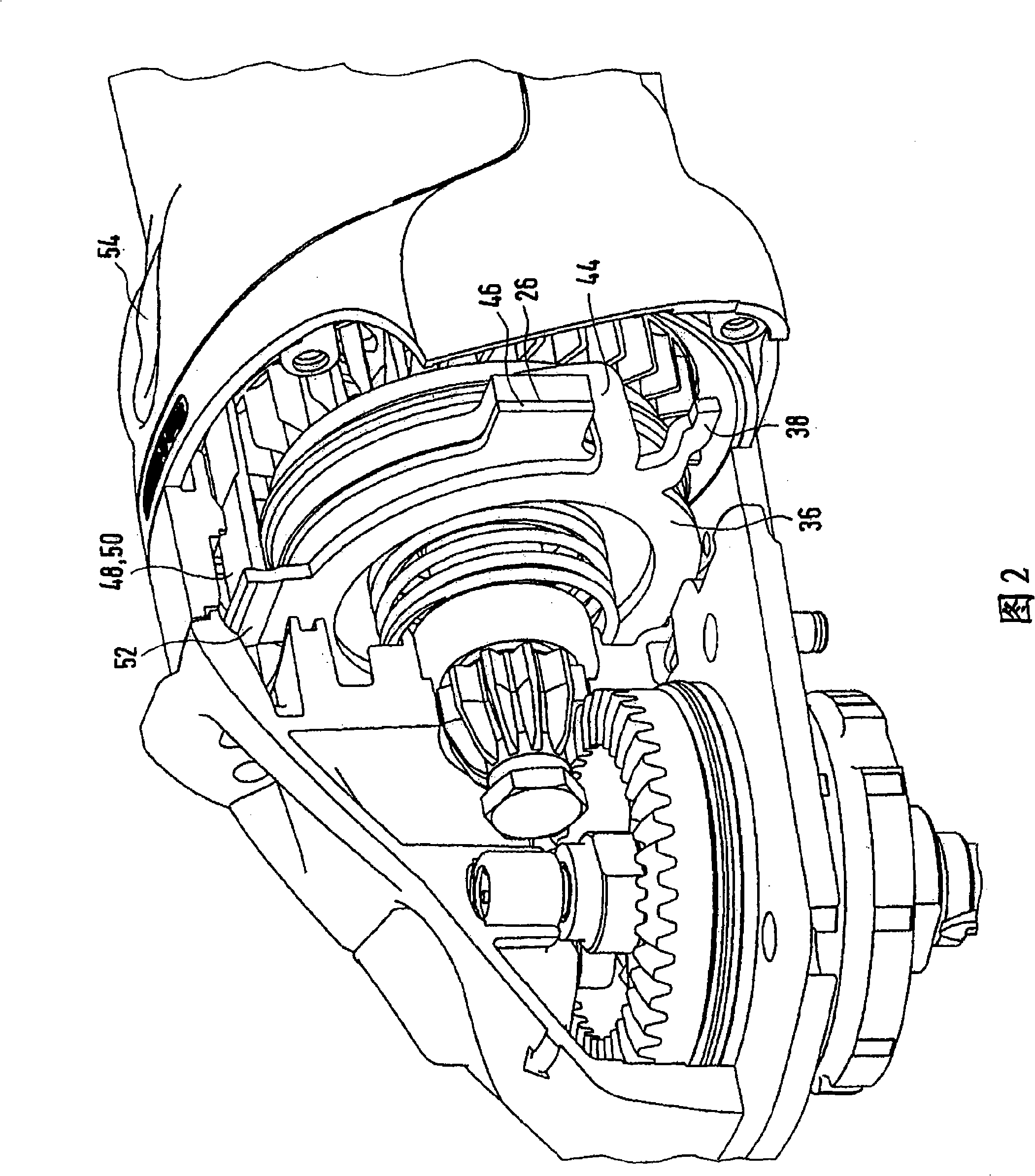

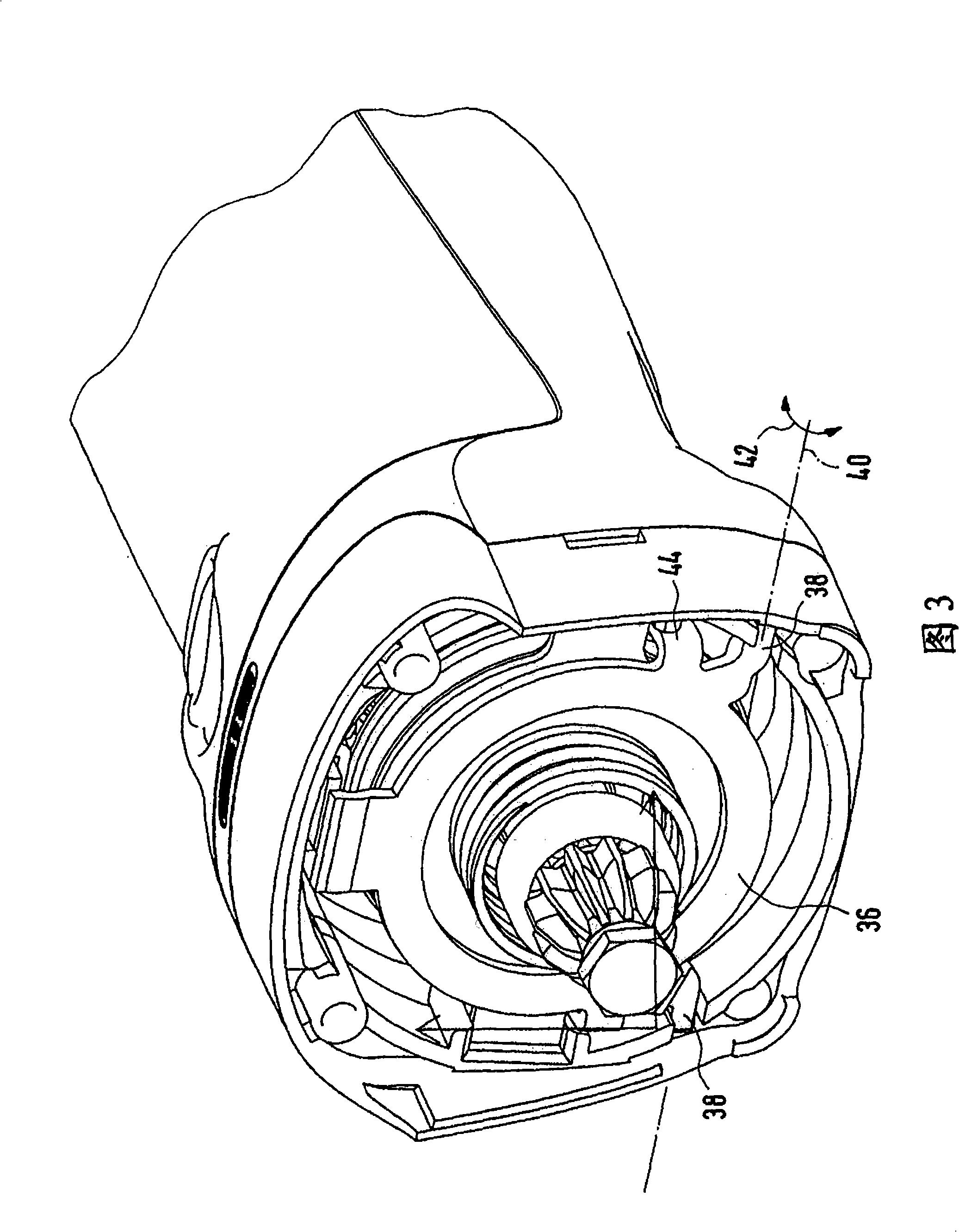

[0025] The figure shows an electric hand-held power tool in the form of a curved handle grinder or a cutting machine marked with the reference numeral 2 as a whole. The machine tool includes a handle part 4 and a transmission mechanism housing part 10, wherein the handle part 4 constitutes the motor housing part 6 at the same time and is connected to the intermediate housing flange 8 which has not been described in detail. The tool spindle 14 is perpendicular to the longitudinal center axis 12 of the machine tool. The ground (see FIG. 4) extends outward from the housing member 10 of the mechanism. A grinding wheel or cutting tool is fixed to the main shaft 14 in a known manner.

[0026] The transmission shaft 18 extends from the electric motor 16 in the direction 12 of the longitudinal center axis through the intermediate housing flange 8 into the transmission housing part 10. The transmission shaft 18 drives the tool spindle 14 through the bevel gear transmission mechanism 20.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com