Sugar industry emulsifying lime slurry centrifugal pump

A lime slurry and centrifugal pump technology, applied in the field of pumps for slurry transportation, can solve the problems of product quality stability and improvement obstacles, serious post-reaction, unstable sugar quality and purity, etc., to achieve the elimination of post-reaction serious, quality and purity Enhancement, quality and purity improvements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

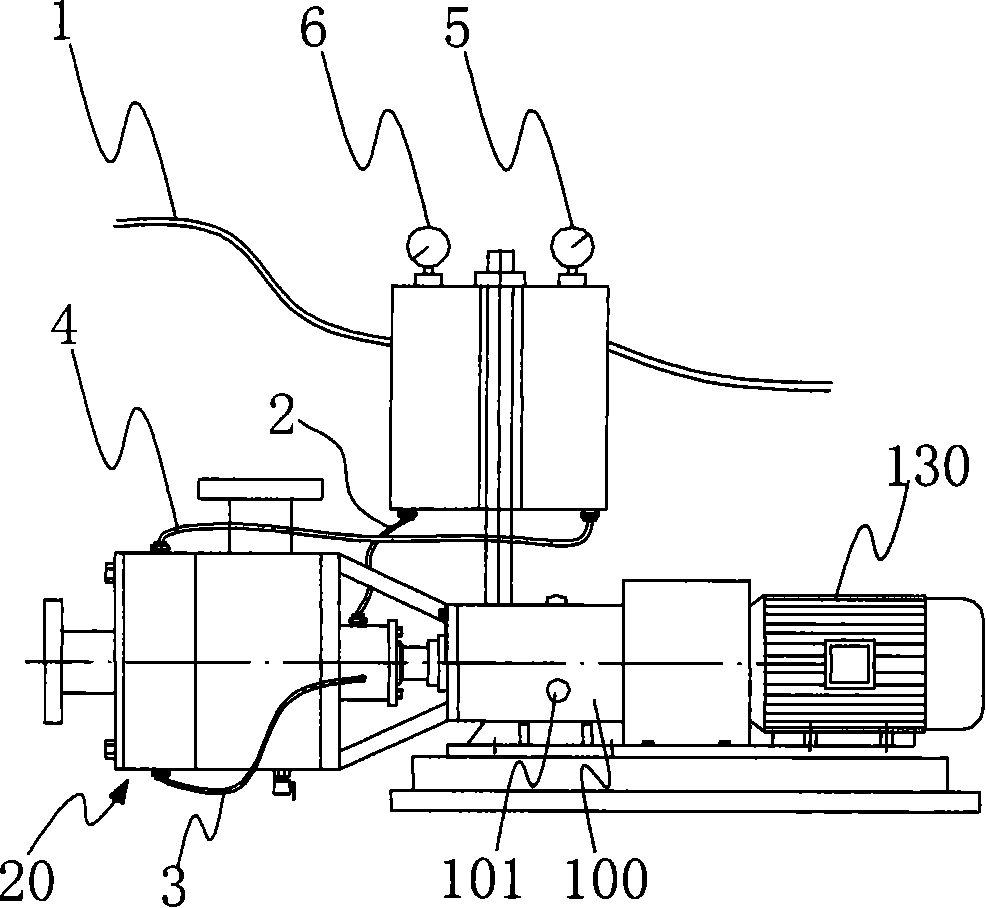

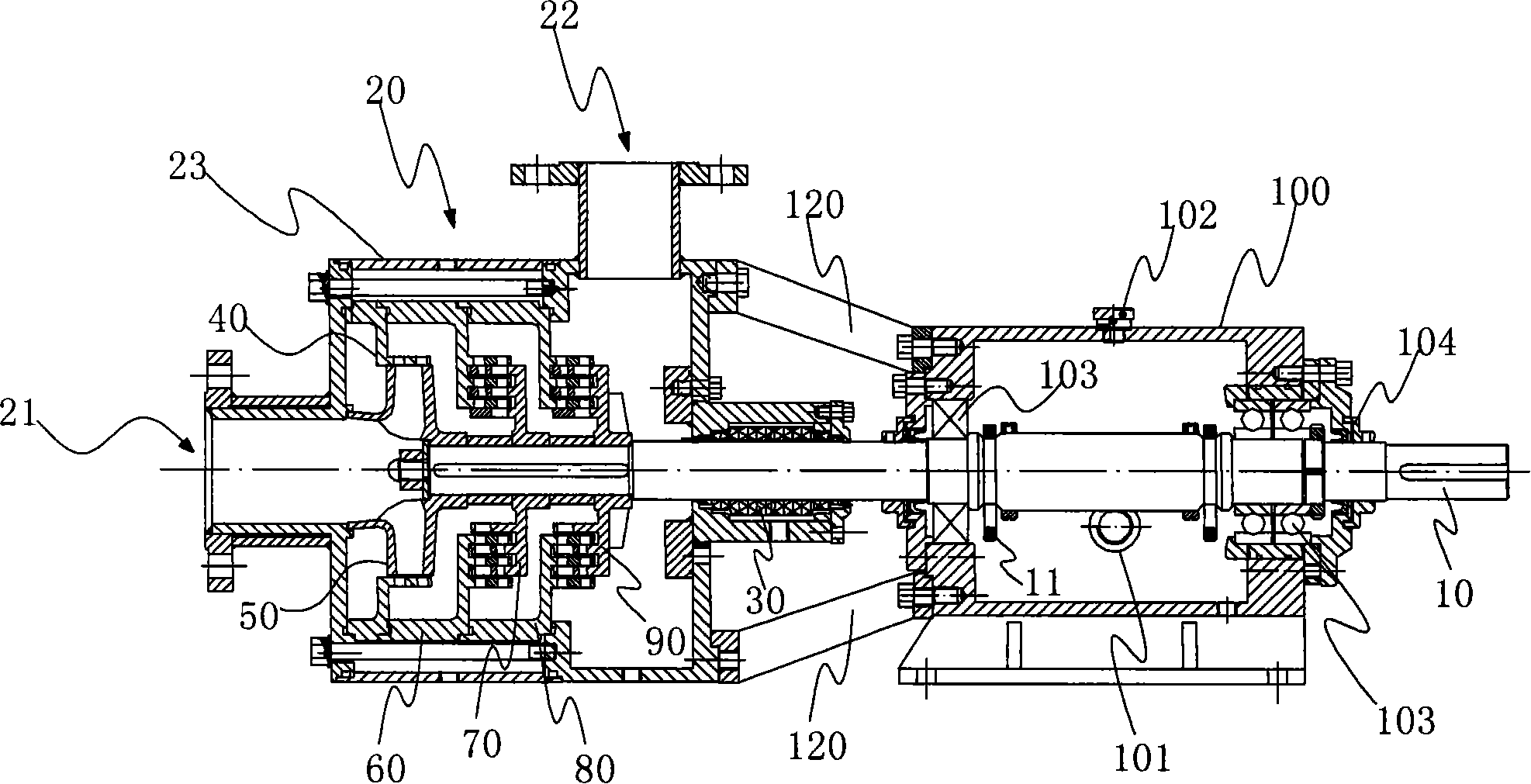

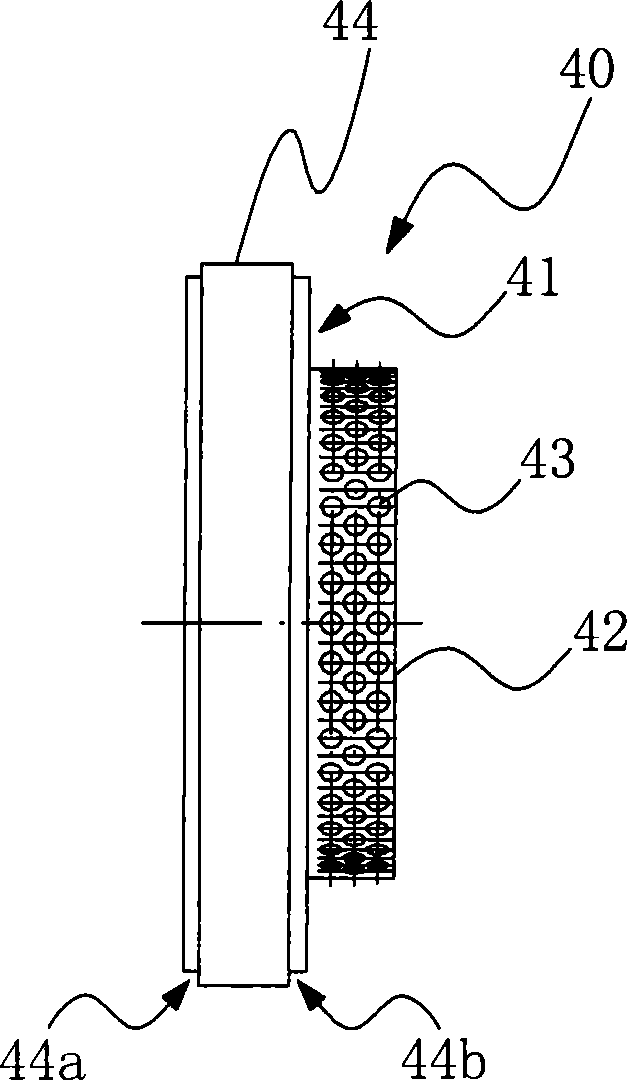

[0014] combine figure 1 , 2 , the sugar industry emulsified lime slurry pump disclosed by the present invention, wherein the front section of the rotating shaft 10 is located in the pump body 20, the pump body 20 is provided with a slurry inlet port 21 and a slurry outlet port 22, and the slurry inlet port 21 and the slurry outlet port The cavity of the pump body 20 between 22 is provided with a first-stage stator 40 and a rotor 50 that cooperate with each other. The middle part of the rotor 50 is fixedly connected with the rotating shaft 10. The pump body 20 is provided with a hole for the rotating shaft 10 to pass through. A sealing assembly 30 is arranged between the rotating shafts 10. The rear end of the rotating shaft 10 is connected to the rotating shaft of the motor 110. The first-stage rotor 50 is centrifugal and cooperates with the first-stage stator 40 to form a radial passage for lime slurry to flow through to form a particle shear. cutting edge.

[0015] In orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com