Machine for fixing wheels on vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Description of the preferred embodiment

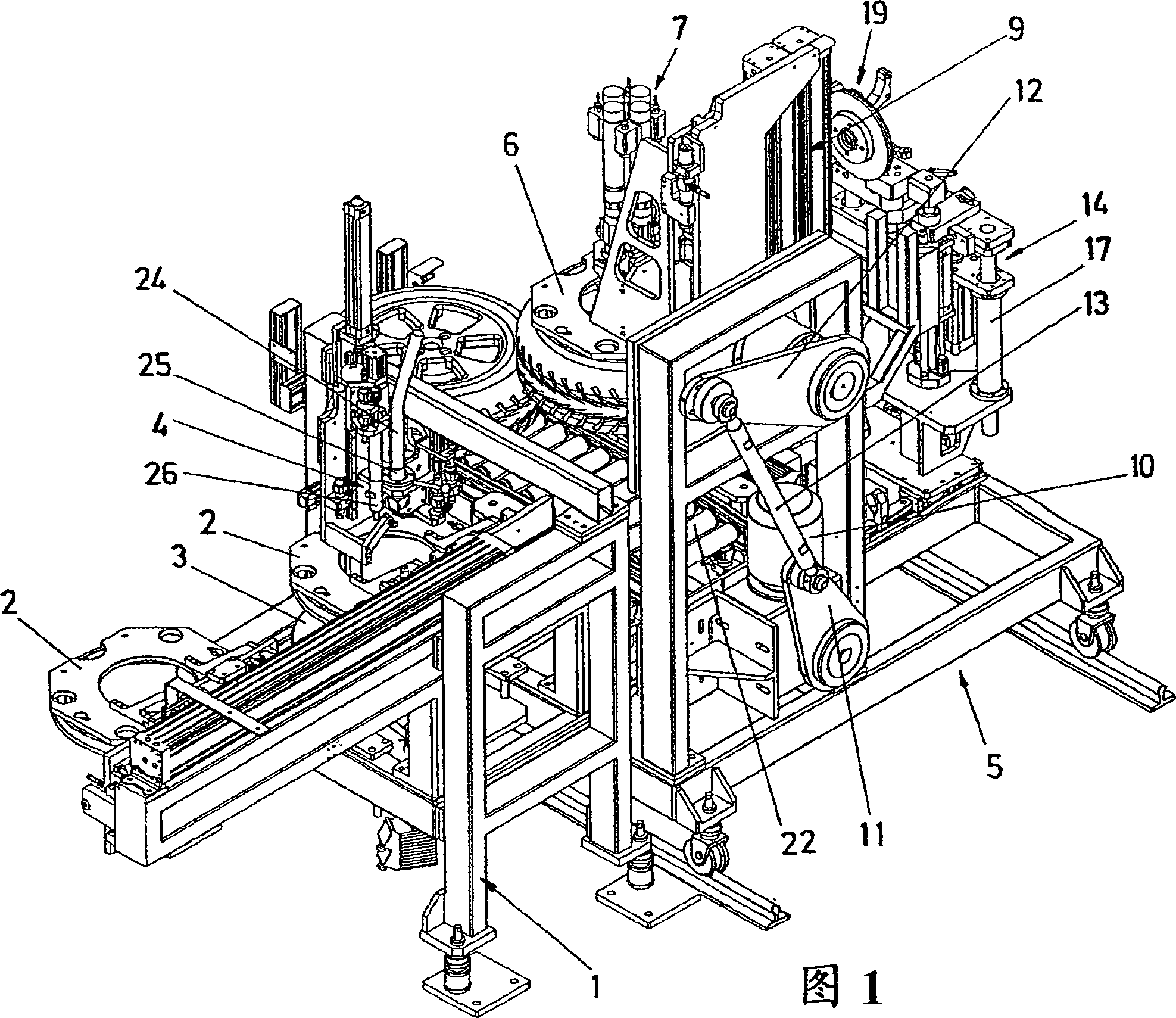

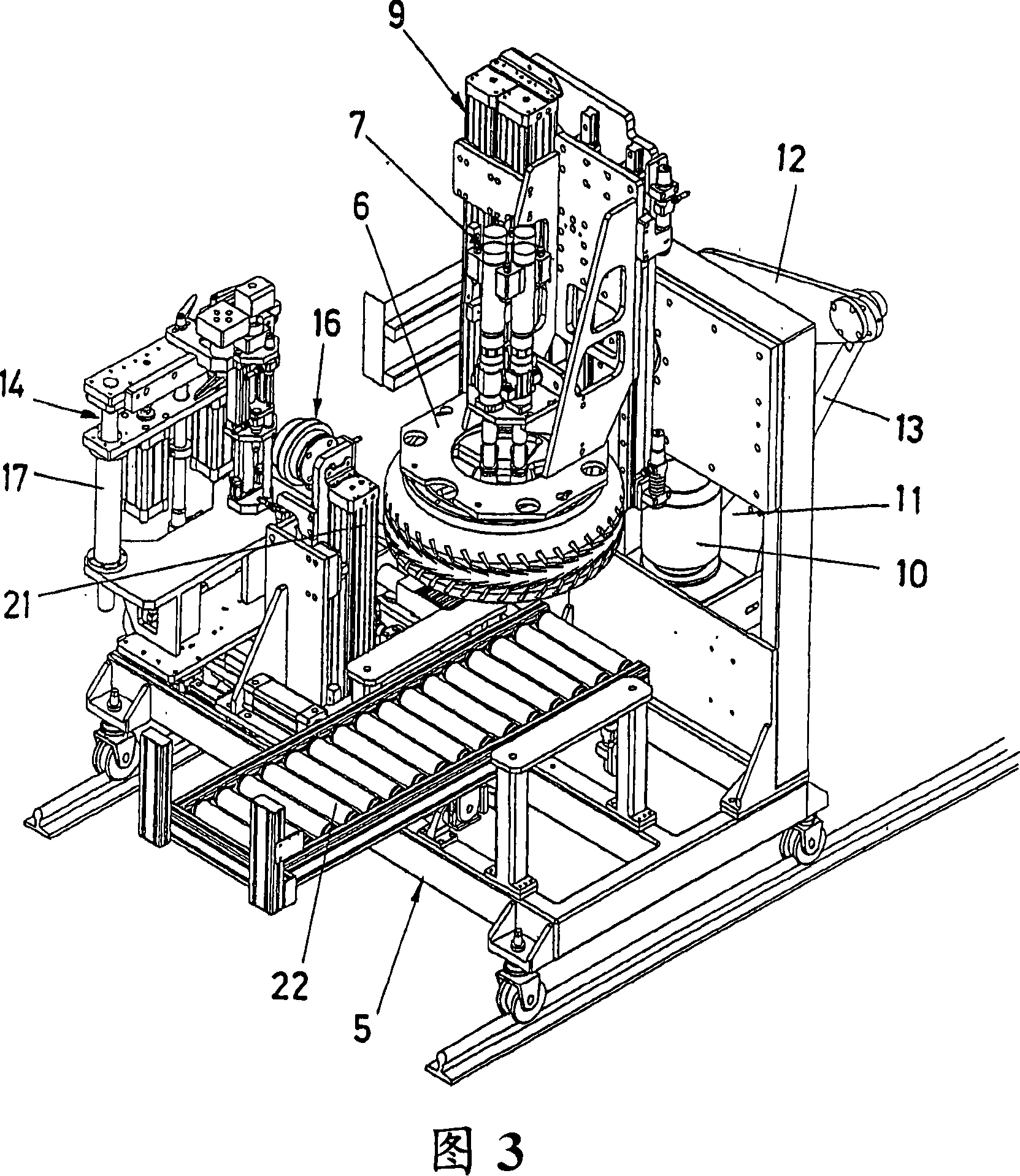

[0039] With reference to the numbered figures listed above, we can see how the object of the invention, functioning as a machine for fastening the wheels to the motor vehicle, provides a base 1 fixed to the ground near the assembly line which transports the vehicles, on which the The wheel is installed automatically. The base 1 receives the wheel onto a positioned centering element that transports the wheel by means of a vertically and horizontally travelable support arm 2 . The arm carries one or more gripping elements which are positioned relative to the tire and have a suction cup effect to effectively grip the wheel.

[0040] Next, the support arm 2 travels horizontally in order to place the wheel on the swivel plate 3 , which is located below the screw supply 4 .

[0041] The rotating plate 3 includes another wheel positioning element operated by means of a photodetector in order to cause the plate 3 to rotate and stop at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com