Conical Z-shaped valve core type electric four-way valve

A four-way valve and valve core technology, which is applied to multi-way valves, valve details, valve devices, etc., can solve the problems of increased steering torque, pressure-holding when the current is cut off, and impact equipment, and can shorten the length of the whole machine. Eliminate the effect of instantaneous pressure holding and water hammer phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

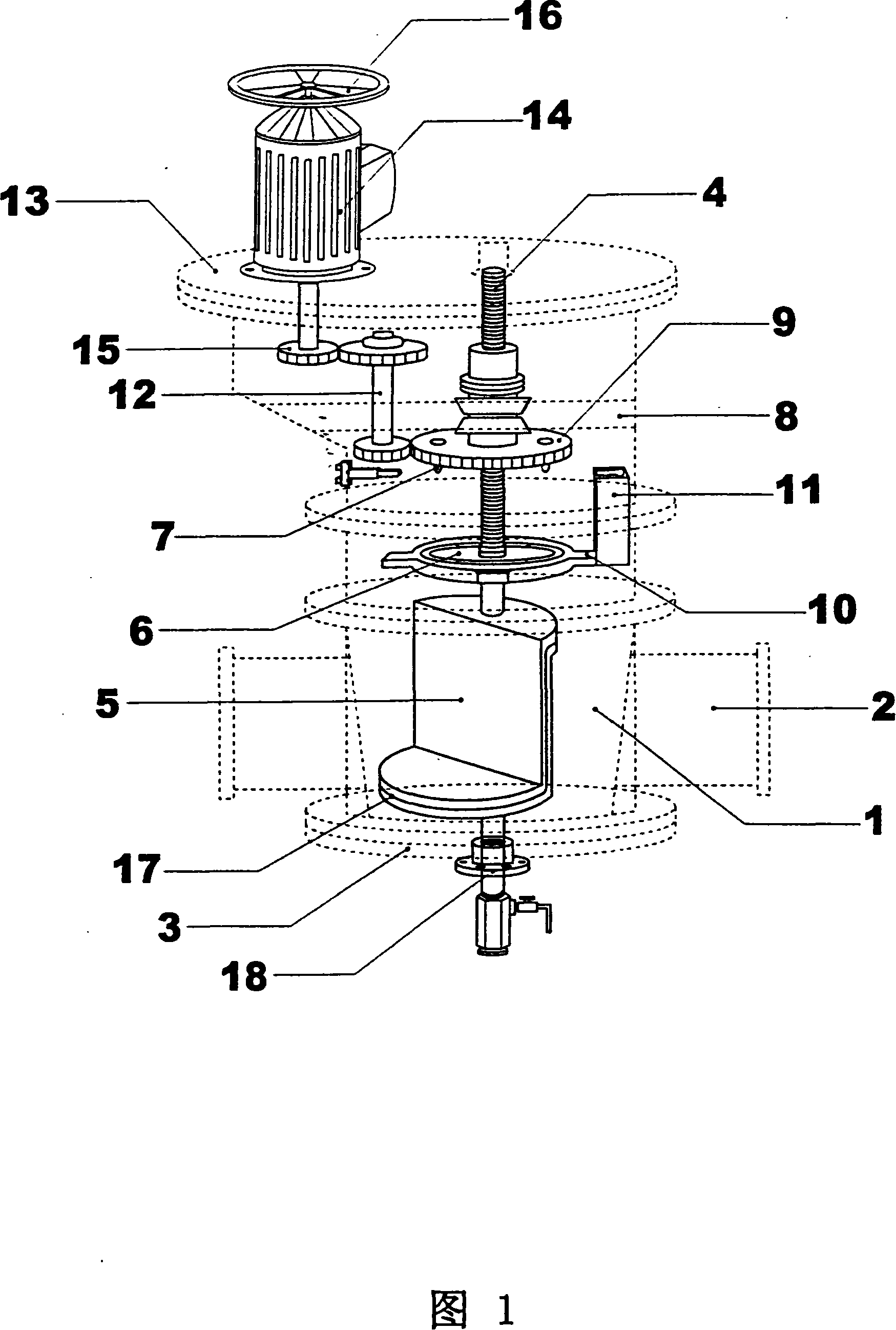

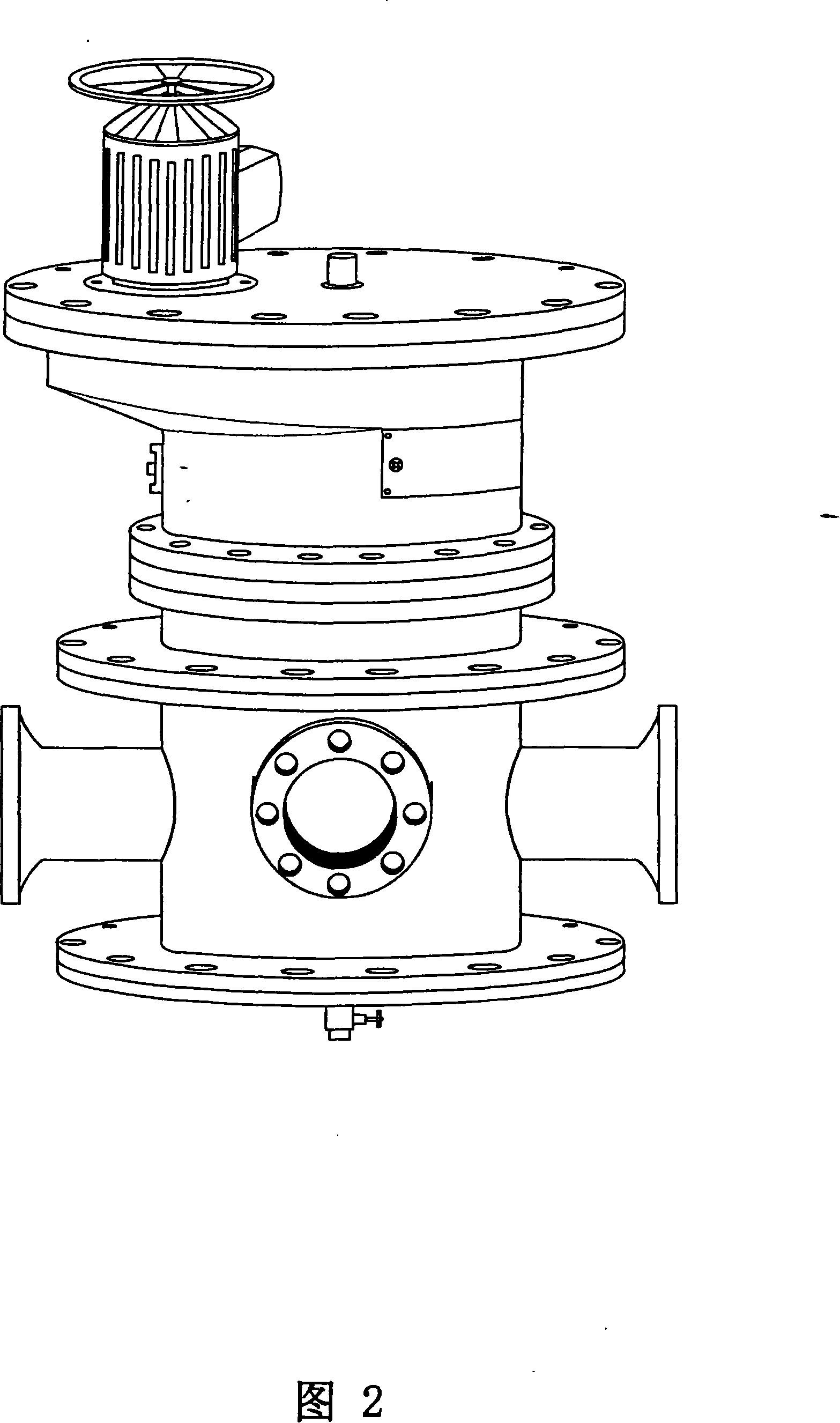

[0010] The present invention will be further described now in conjunction with accompanying drawing,

[0011] Cone Z-shaped spool type electric four-way valve, including valve body and spool, is characterized by: a thick wall, the inner cavity is the bottom of the conical cylindrical valve body 1, protruding outward on the same horizontal plane and perpendicular to each other Four liquid pipes 2, the bottom of the valve is sealed by a flange 3 with a leak detection valve 18, the center of the flange passes through the main shaft 4 with a screw on the upper part, and the main shaft passes through the edge with a sealing ring 17 placed in the cone cavity in turn The Z-shaped spool 5, the indexing circle 6, and the two backstops 7 protruding downwards are fixed on the main gear 9 of the partition 8. The center of the main gear has an internal thread meshing with the screw rod; the main shaft and the Z-shaped spool , the indexing circle is fastened; the indexing circle stretches o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com