Modified acrylic acid oligomer and dirt-resisting paint containing the oligomer

A non-toxic acrylic acid and oligomer technology, applied in antifouling/underwater coatings, biocide-containing paints, coatings, etc., can solve the problems of unfavorable environmental protection, slow curing speed, volatile coatings, etc., and achieve durable anti-corrosion Pollution effect, good anti-fouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

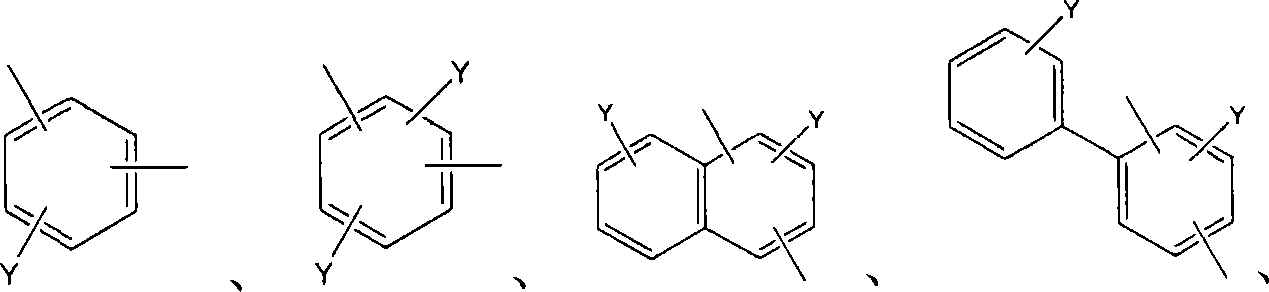

[0062] The preparation method of the modified acrylic acid oligomer of the present invention is not particularly limited, and the modified acrylic acid oligomer can be prepared by any well-known method of those skilled in the art of the present invention. In the present invention, monomers such as acrylic monomers, fluorinated acrylic monomers and / or siloxane monomers and optional tertiary carboxylate monomers are mixed with appropriate initiators and solvents to carry out Polymerization reaction, and then modify the polymerization product with modifier. The types of initiators and solvents used in the above polymerization reaction are not particularly limited, and are well known to those skilled in the art to which the present invention pertains.

[0063] The modified acrylic oligomer prepared by the present invention has fluorocarbon side chains and / or silicone side chains with low surface energy, which can provide good water repellency and antifouling properties, so it can ...

preparation example

[0096] Preparation of oligomers: Take different proportions of monomers, solvents and appropriate initiators to prepare mixtures 1 and 2 of oligomers and solvents for further modification. The preparation conditions are shown in Table 1 below:

[0097] Table 1

[0098] mixture

1

2

monomer type

and dosage (grams)

AAA

13.4

10.5

MAA

0.6

0.6

MMA

39.6

21.8

BA

17.1

--

2-HPMA

13.2

31.5

Zonyl TM

7.0

3.6

Veova 10

46.6

18.6

n-BMA

--

10.5

IBMA

--

21.8

AS

--

7.0

88

111

Solvent (PMA) (g)

17.6

17.6

Initiator (TBPB) (g)

0.5

3.0

Reaction temperature (°C)

130℃

130℃

time

8 hours

8 hours

Solid co...

Embodiment 1-4

[0107] The mixtures 1 and 2 prepared above were respectively reacted with modifiers A and B to modify the oligomer. Subsequently, the reaction product is mixed with comonomer and other additives to obtain the antifouling coating of the present invention, and the preparation conditions are as shown in Table 2:

[0108] Table 2

[0109] Example

1

2

3

4

(gram)

Mixture 1

171

165

--

--

mixture 2

--

--

171

165

Modifier A

80

--

70

--

Modifier B

--

68.7

--

60.1

HDDA

60

60

60

60

1 Etermer 231

186.6

186.6

186.6

186.6

2 Irgacure 184

12.44

12.44

12.44

12.44

Benzophenone (Benzophenol)

12.44

12.44

12.44

12.44

3 Etercure 6420

31.1

31.1

31.1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com