Location racks of apparatus for fixing goods

A positioning frame and cargo support technology, applied in the direction of freight vehicles, load fixing, motor vehicles, etc., can solve the problems of inconvenient use, large iron frame size, poor use stability, etc., to achieve convenient processing, The effect of long service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

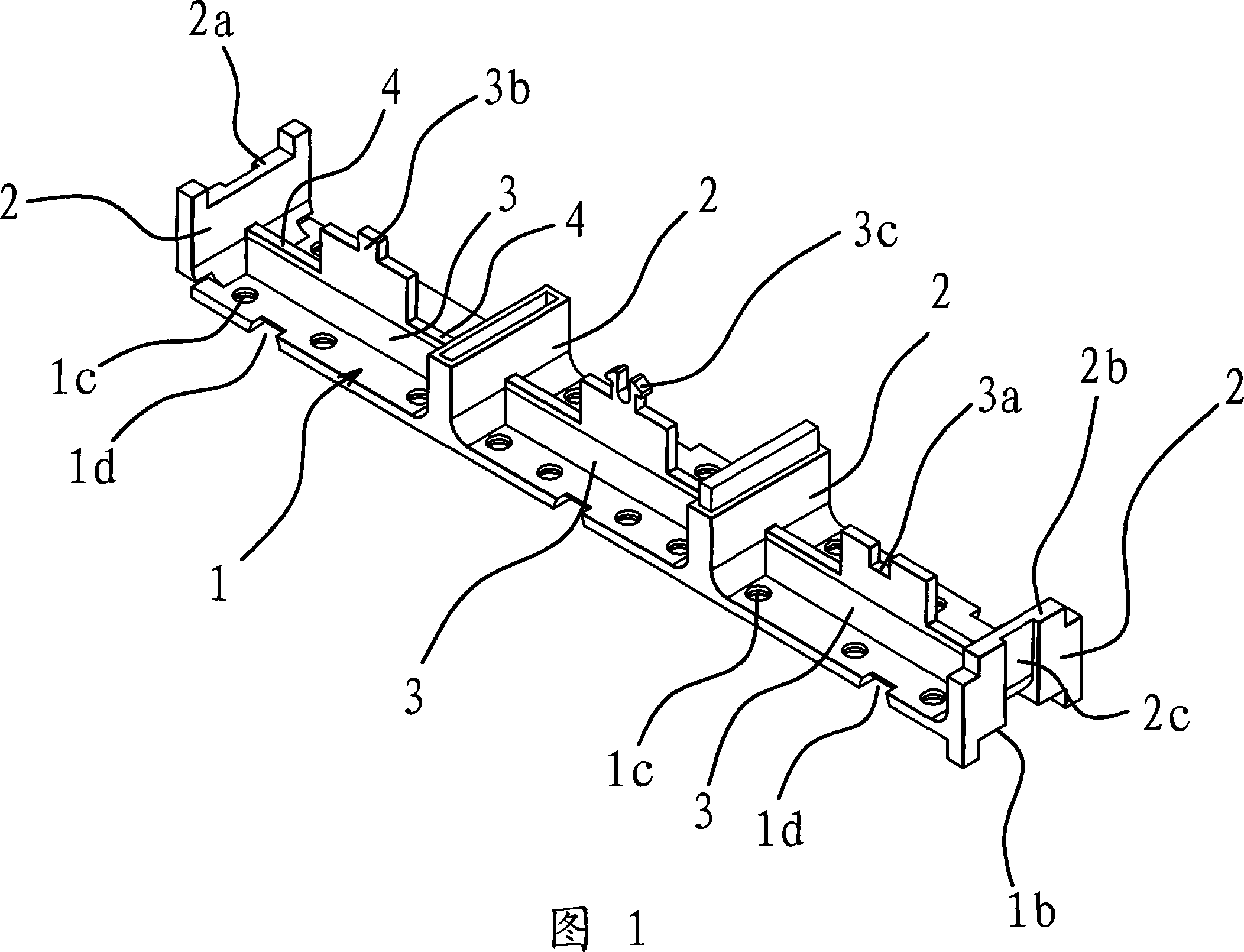

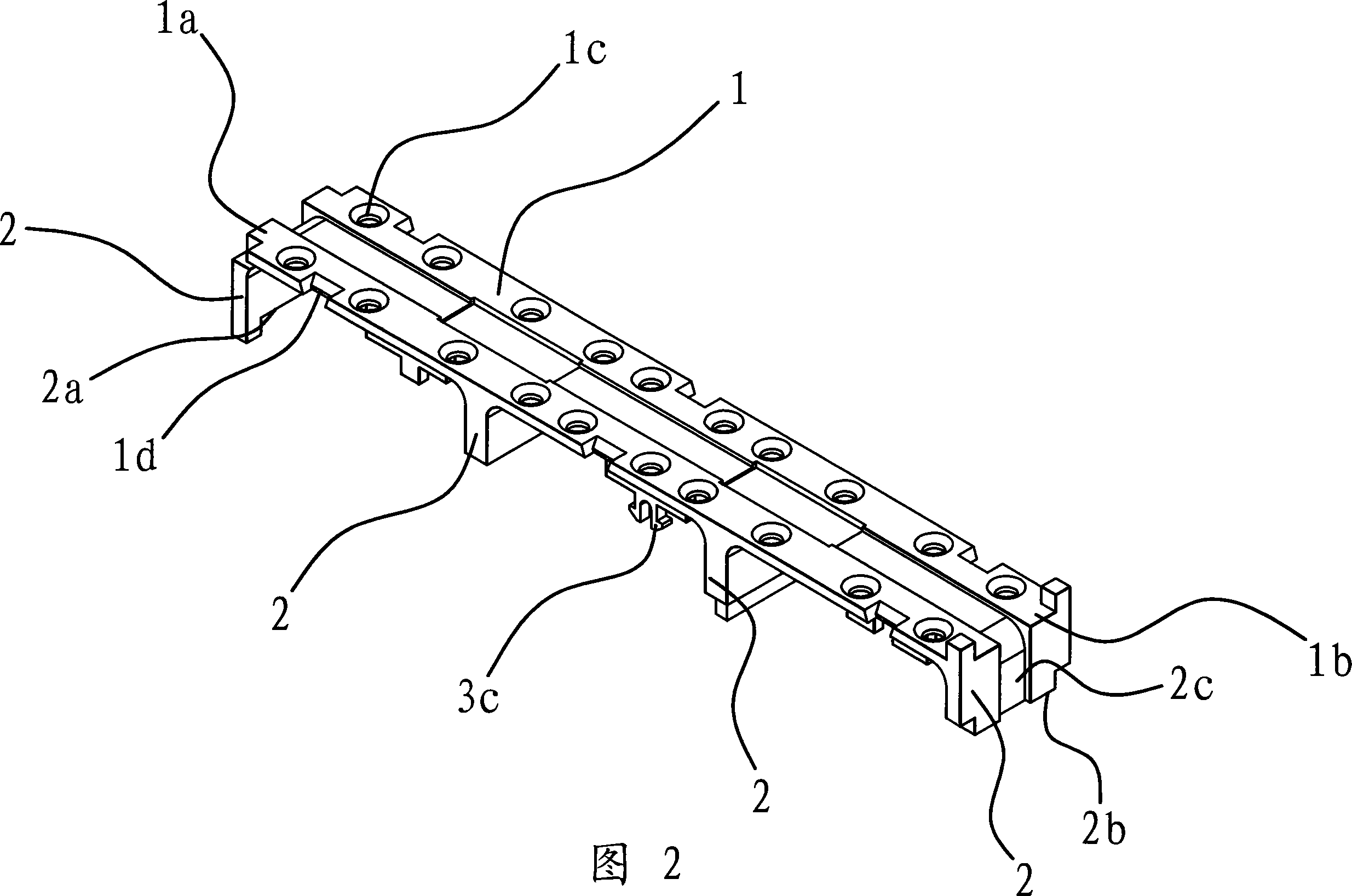

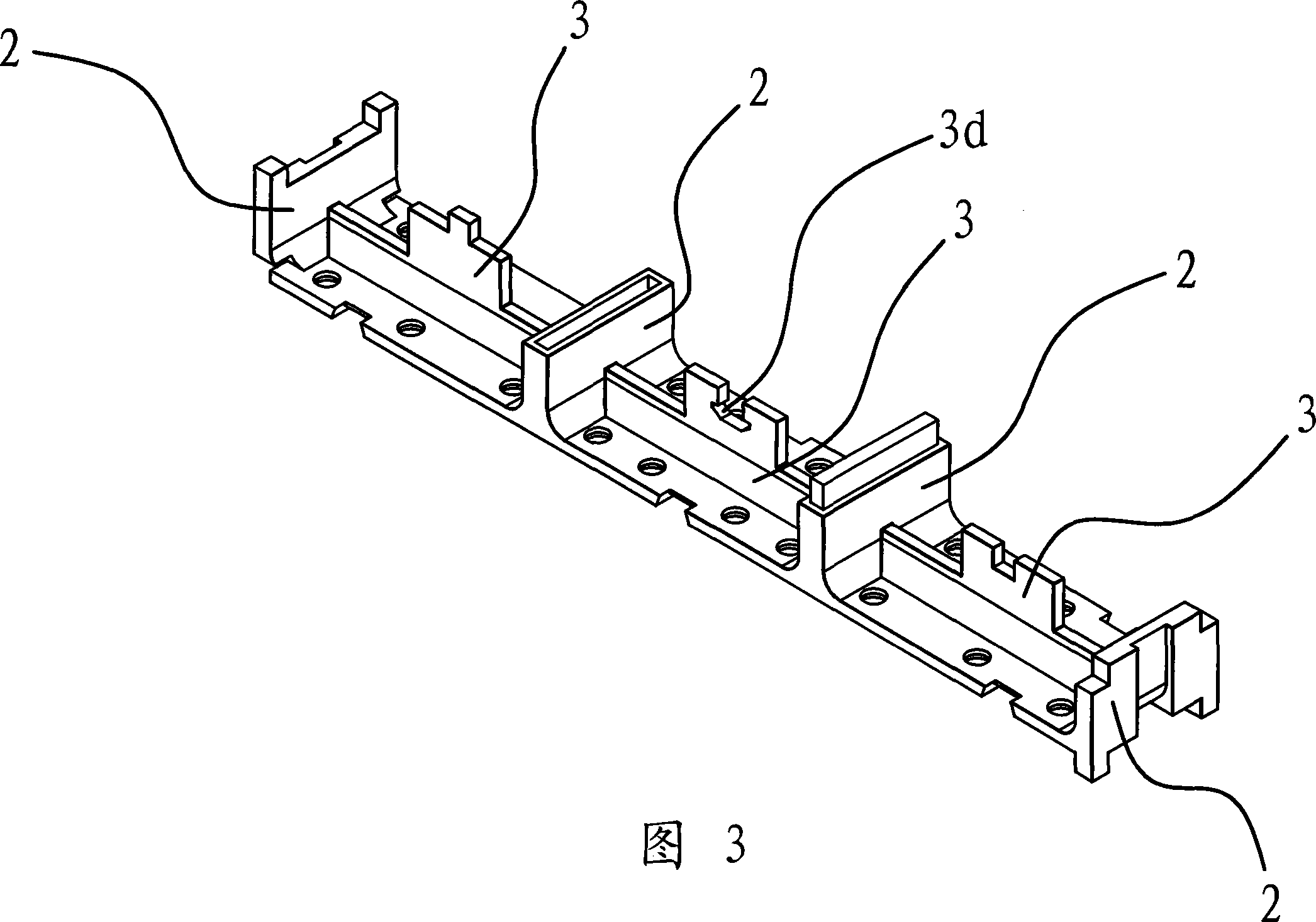

[0033] The positioning frame of the cargo supporter is used to fix multiple cargo supporters, and it includes several bodies 1 .

[0034] Such as figure 1 with figure 2 As shown, the body 1 is in the shape of a long plate, and there are four baffles 2 on the body 1 . Four baffles 2 are located on the upper side of the body 1 and they are arranged longitudinally along the body 1 , and the four baffles 2 are arranged symmetrically around the center of the body 1 . Two baffles 2 are located at two ends of the body 1 respectively. The baffle plate 2 has a snap joint part 1 2a, and the other baffle plate 2 symmetrical to the middle part of the main body 1 has a snap joint part 2 2b on the baffle plate 2, and the snap joint part 2b is opposite to the snap joint part 1 2a. match.

[0035] In this embodiment, the first clamping part 2a on the baffle plate 2 at both ends of the body 1 is an upper notch, and the second clamping part 2b is an upper protrusion, and the upper notch ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com