Double-speed recoiler

A quick-winding and winding machine technology, applied in the field of winding machines, can solve the problems of large investment in equipment, high production costs, and occupying a large amount of space in the production site.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

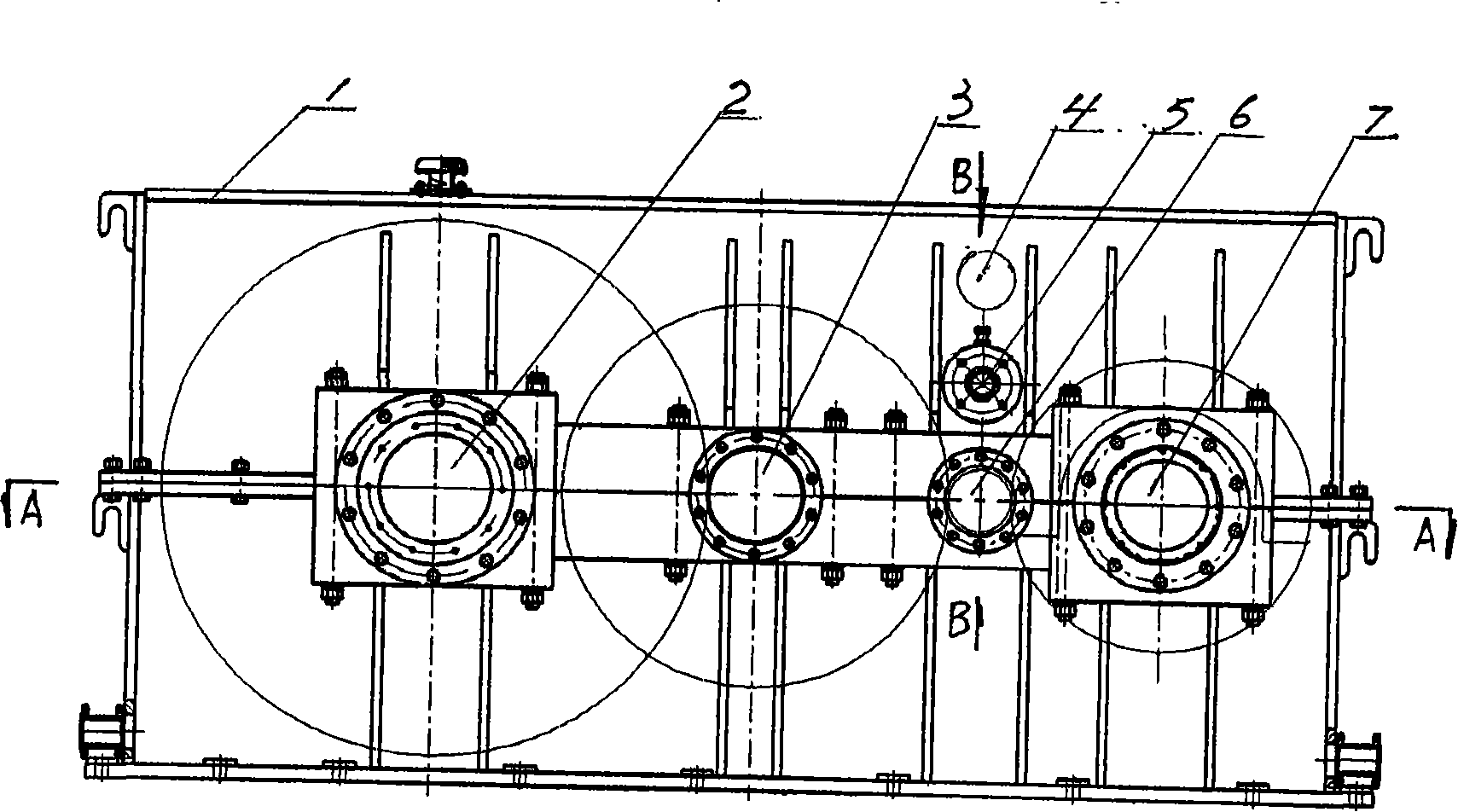

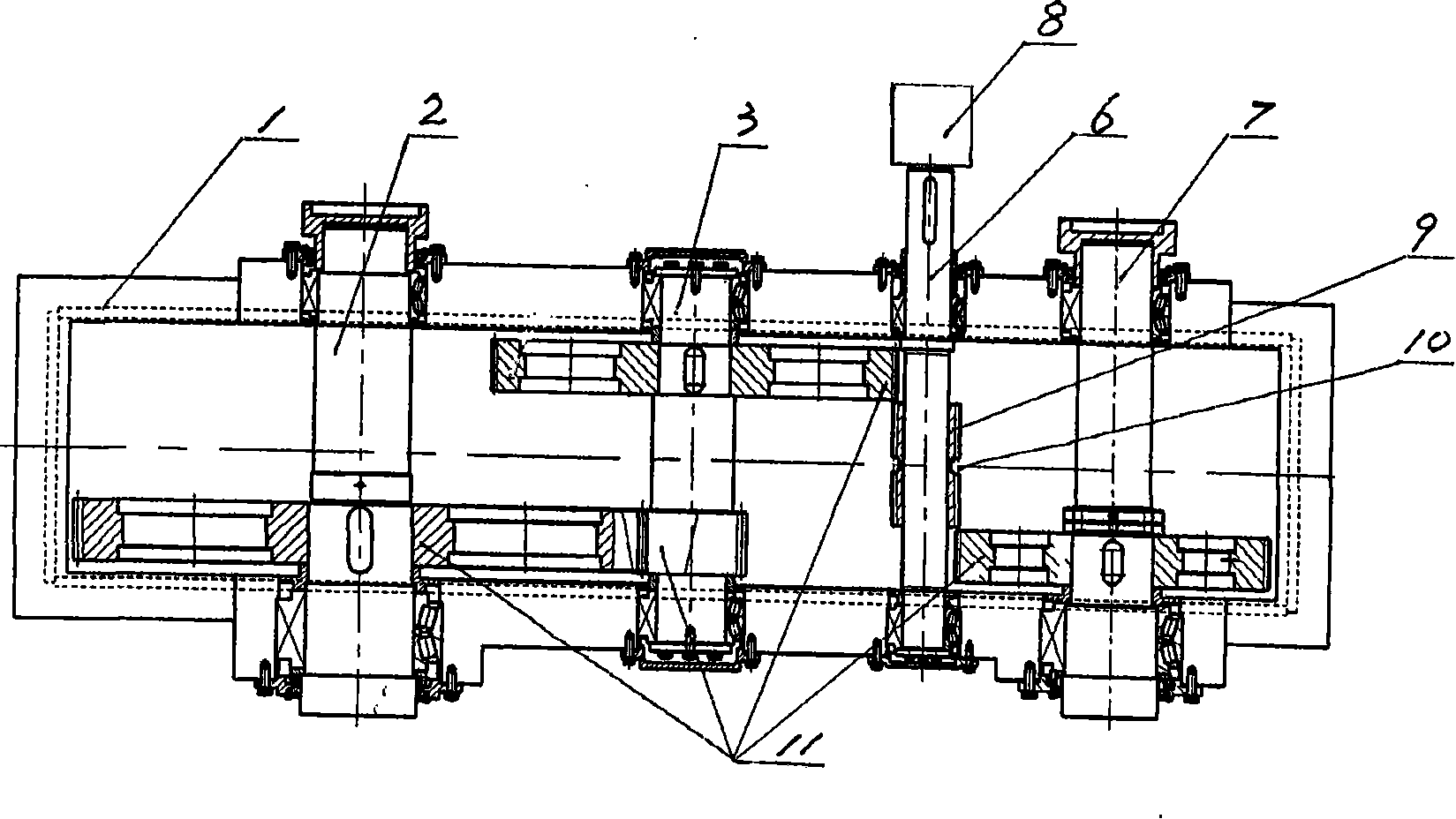

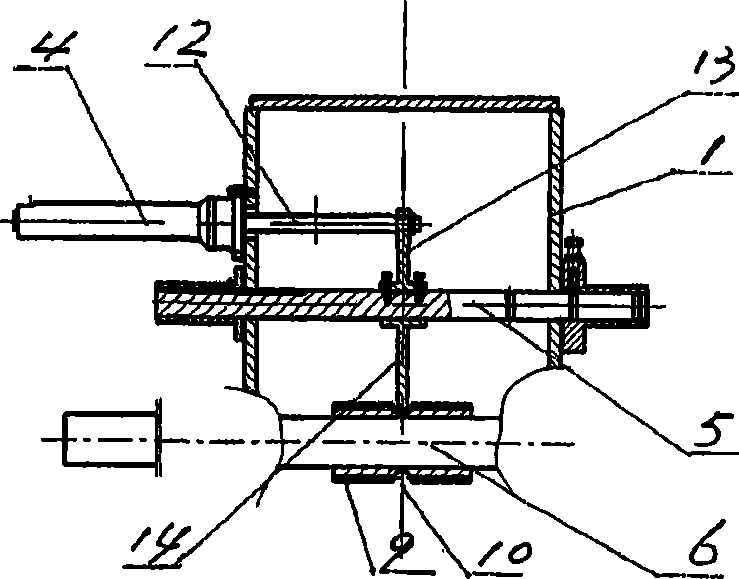

[0013] like figure 1 , figure 2 and image 3 As shown, the two-speed winder of the present invention contains a frame 1, a power shaft 6, a power mechanism 8 and a winding shaft. The frame 1 is a cuboid box-shaped structure, three shaft holes are processed on its two side walls, the three shaft holes on each side wall are at the same height, and the three shaft holes on the two side walls The holes correspond one by one. Wherein, the two ends of the power shaft 6 are rotatably installed in the middle shaft hole on the two side walls by means of bearing seats and bearings respectively. Said power mechanism 8 is arranged on the outside of the frame 1, and the power mechanism is an electric motor whose output shaft is connected with one end of the power shaft 6. The rewinding shaft includes a high-speed rewinding shaft 7 and a low-speed rewinding shaft 2, the two rewinding shafts are respectively located on both sides of the power shaft 6, and their two ends are rotatably in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com