Method for controlling water-power ratio of bone cement and hardening time

A technology of hardening time and impedance control, applied in the field of bone cement manufacturing, can solve problems such as lack and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

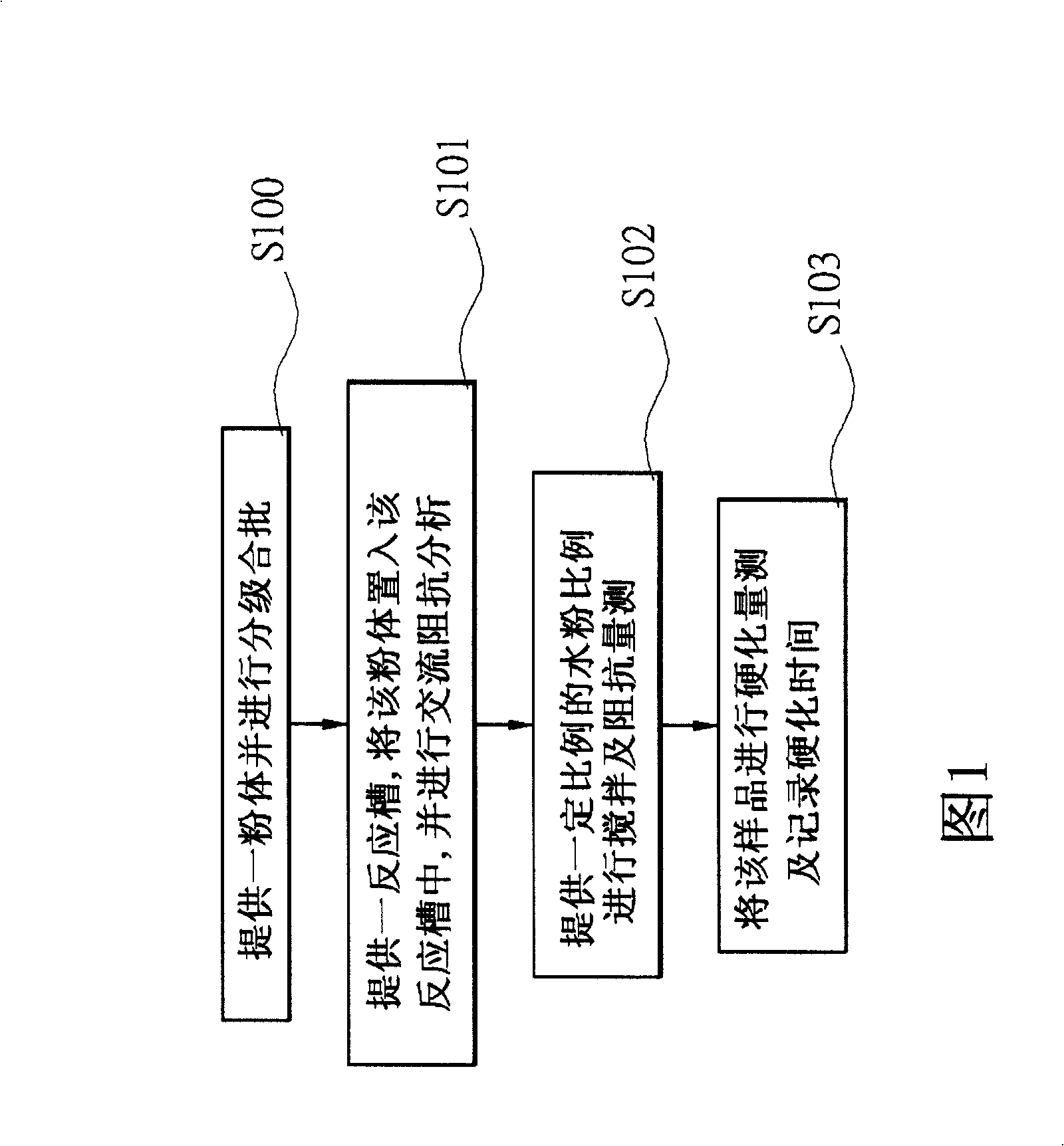

[0018] Please refer to Fig. 1, the present invention provides a method for utilizing impedance to control bone cement-water-powder ratio and hardening time, comprising: providing a powder and grading and batching (S100); providing a reaction tank, placing the powder into the reaction tank, and conduct AC impedance analysis (S101), provide a certain proportion of water-powder ratio for stirring and impedance measurement (S102), and measure the hardening of the sample and record the hardening time (S103). Wherein the powder is calcium sulfate hemihydrate powder, and the calcium sulfate hemihydrate powder is mainly composed of 200 mesh powder. The reaction tank is an acrylic plate, and the reaction tank has a rectangular groove, and copper glue is arranged on both sides of the groove as electrodes. In this step, an AC impedance analysis (S101) is carried out by means of an electrochemical three-electrode method. The parameters of the AC impedance analysis are an applied voltage o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com