Non contact Ra radiation character etching process and its device

A non-contact, laser engraving technology, used in semiconductor/solid-state device manufacturing, electrical components, programming, etc., can solve the problem of flat corners of wafers, surface missing corners, wafer dirt and fragments, wafer fragments, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

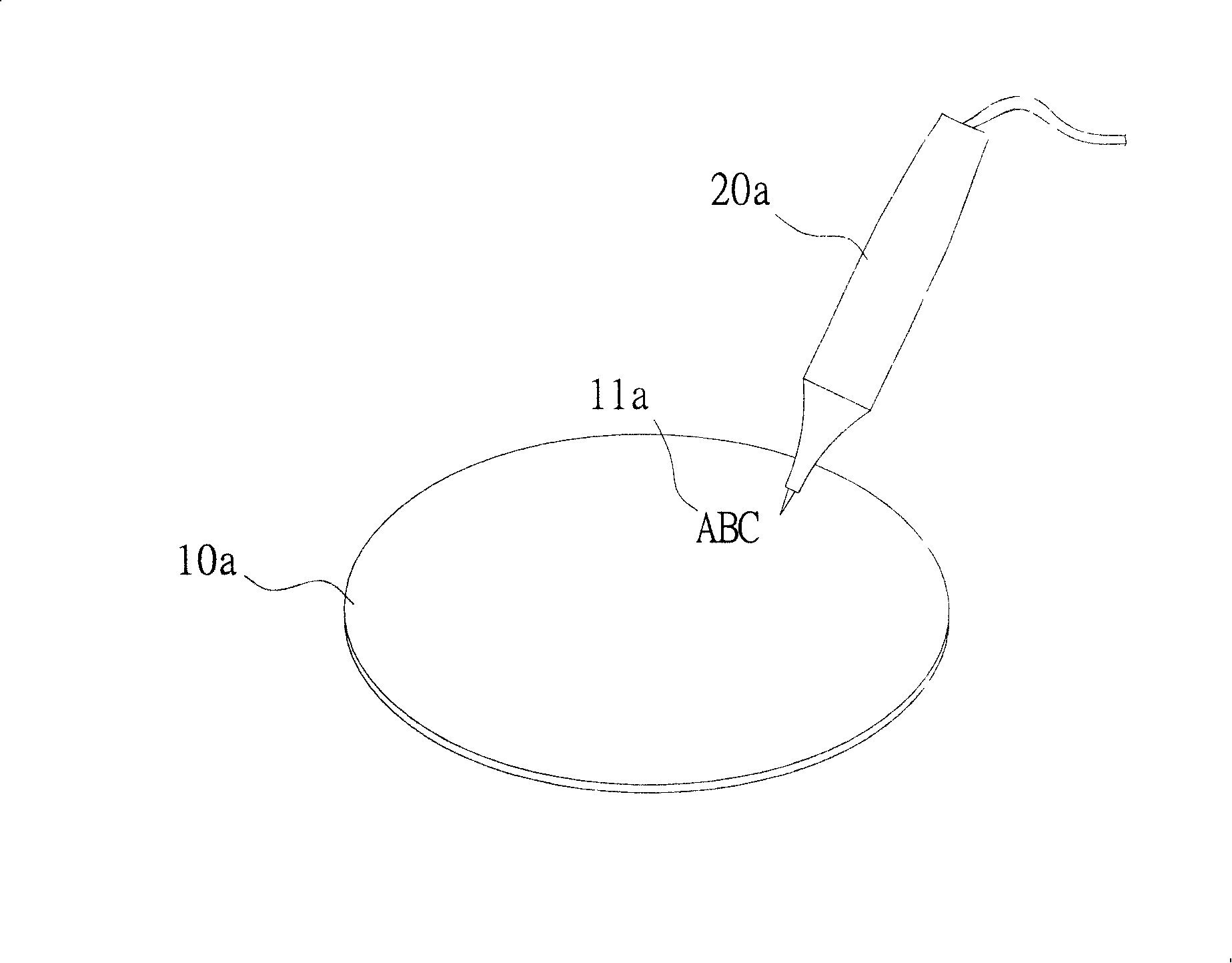

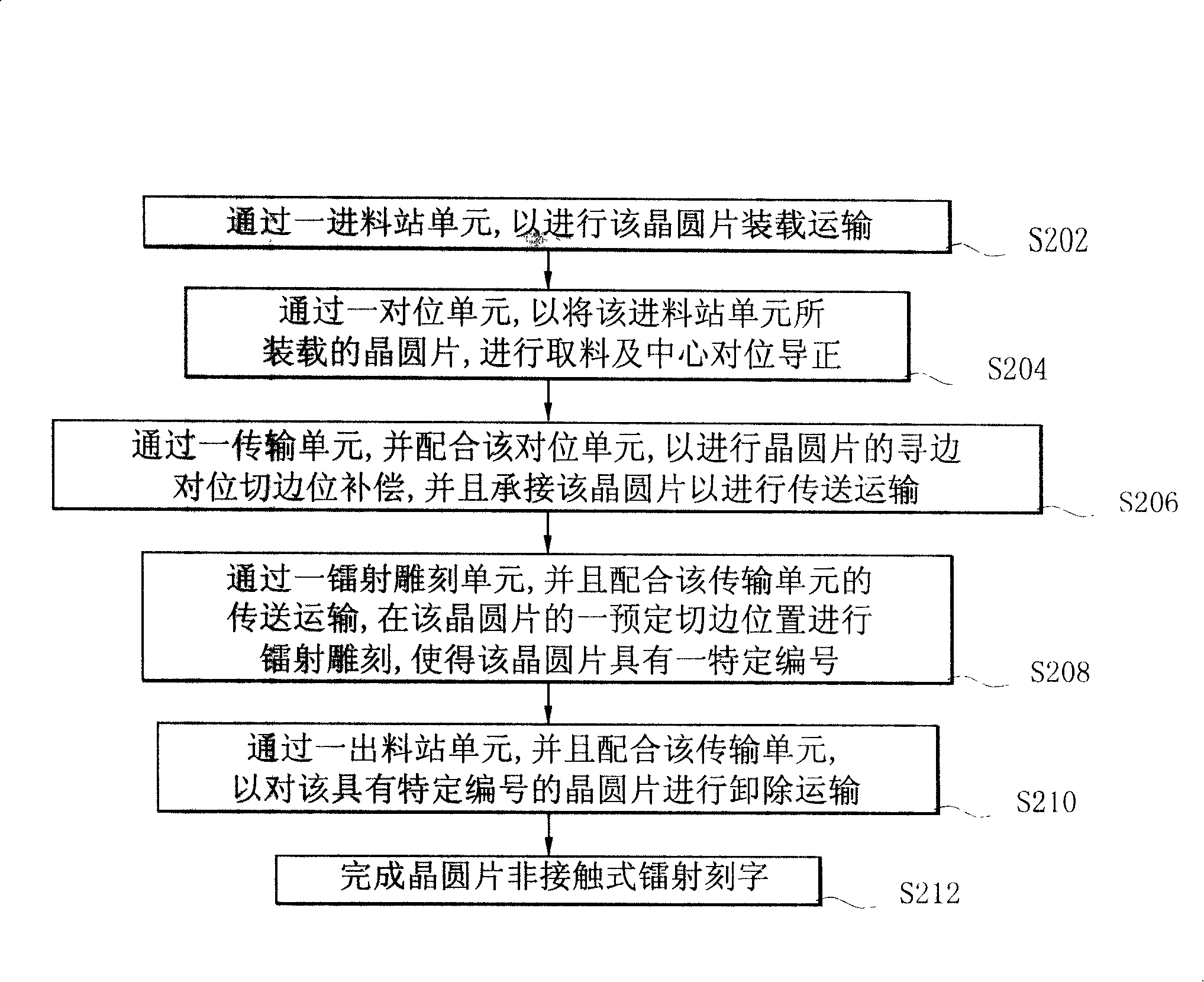

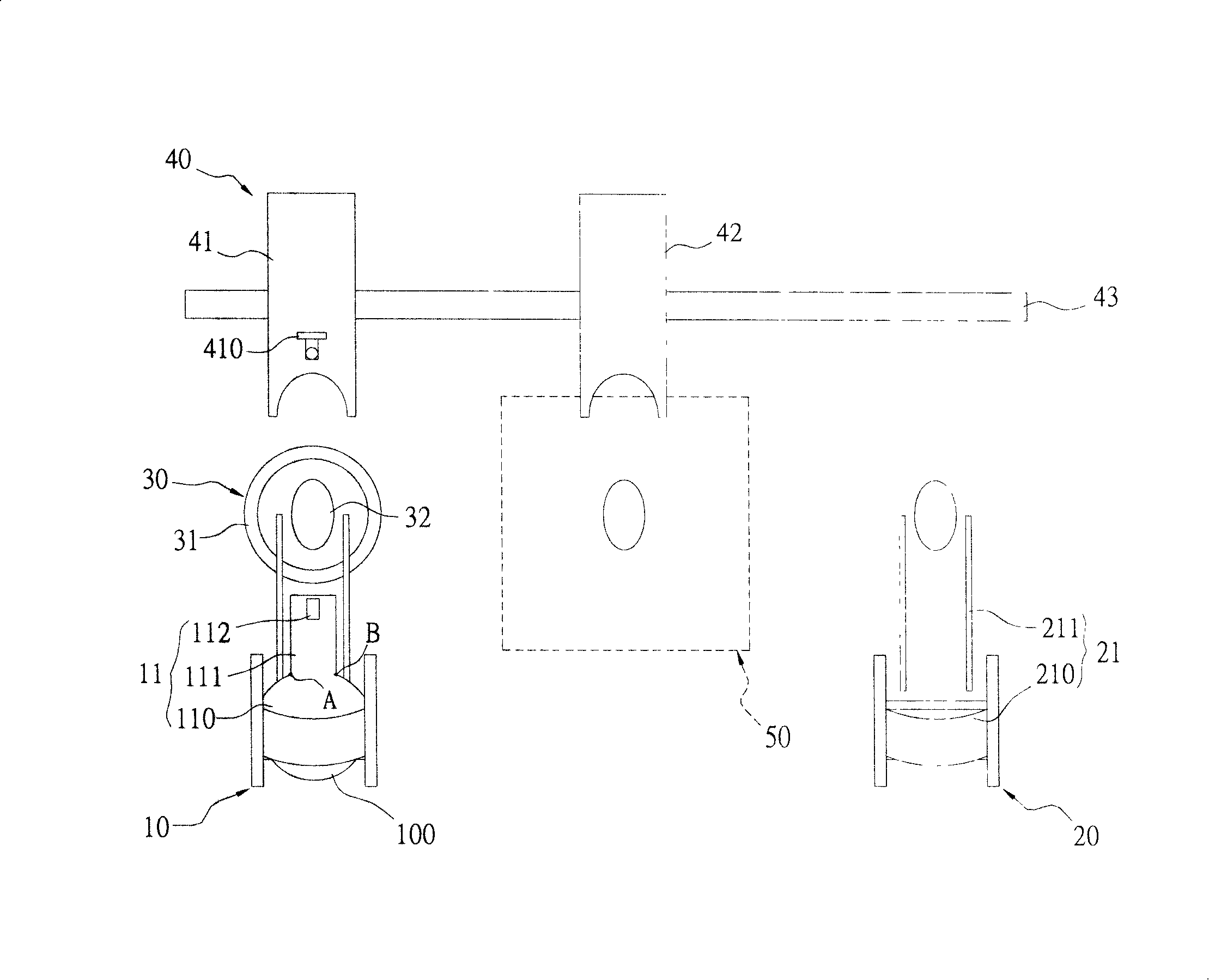

[0058] see figure 2 and image 3 As shown, it is a schematic diagram of a non-contact laser engraving process and its equipment in the present invention, which is used to laser engrave each wafer 100 to generate a specific number, and pass the specific number of each wafer 100 Numbering facilitates effective tracking management, quantity statistics and quality control during the production and transportation of the wafer 100. The steps of the non-contact laser inscription process include: first, through a feeding station unit 10, to carry out loading and transportation of the wafer 100 (S202); The wafer 100 is taken out and the center alignment is performed (S204); and then, through a transmission unit 40, and with the alignment unit 30, the edge-seeking alignment and trimming compensation of the wafer 100 is performed. And accept the wafer 100 for transport (S206); then, through a laser engraving unit 50, and cooperate with the transport of the transport unit 40, laser engr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com