Mine heat conversion circulating production system

A technology of thermal energy conversion and production system, which is applied in mine/tunnel ventilation, mining equipment, earth-moving drilling, etc. It can solve the problems of ineffective utilization of mine heat and ineffective utilization of heat damage in working faces, and achieve good economic benefits. , the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

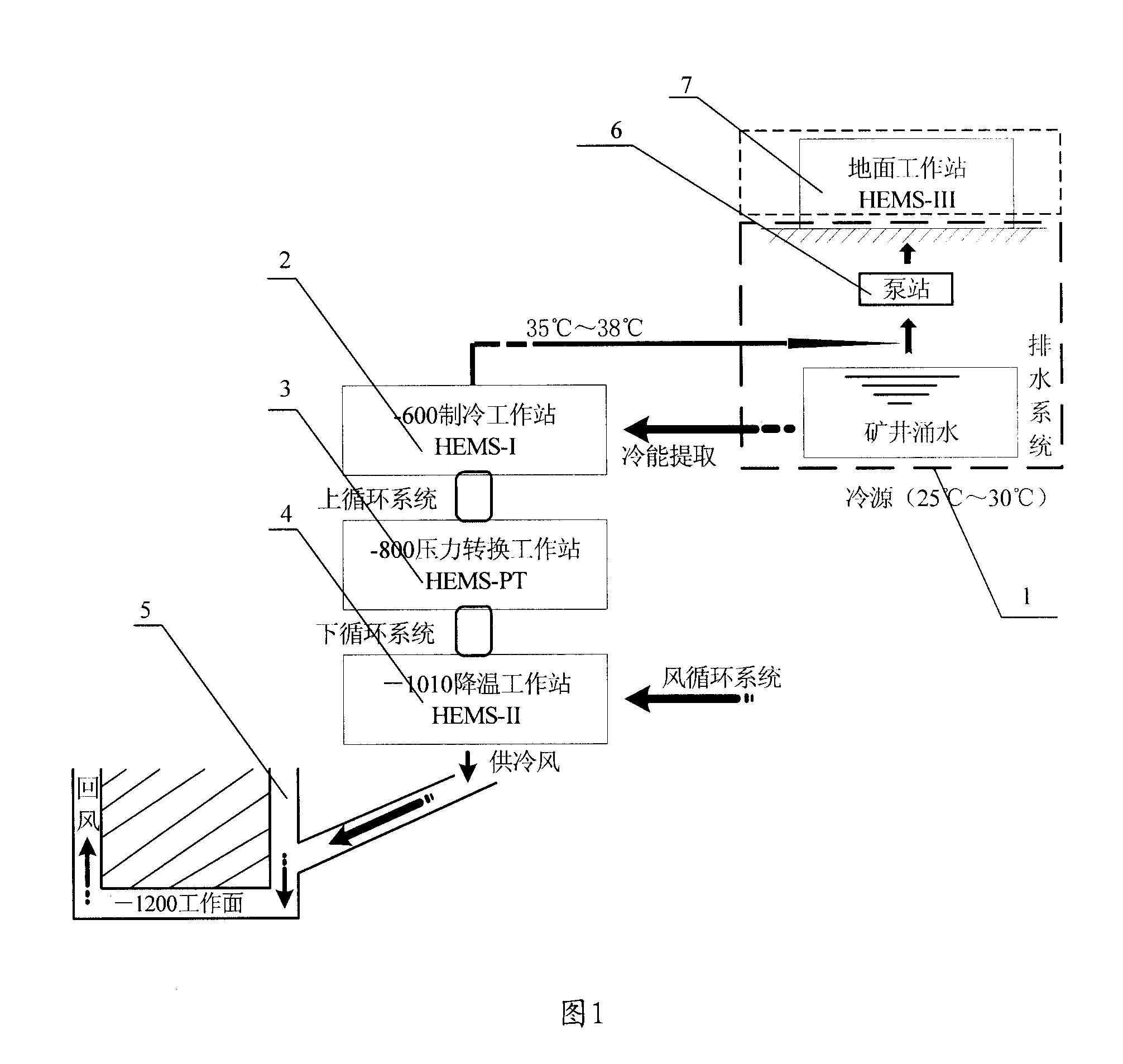

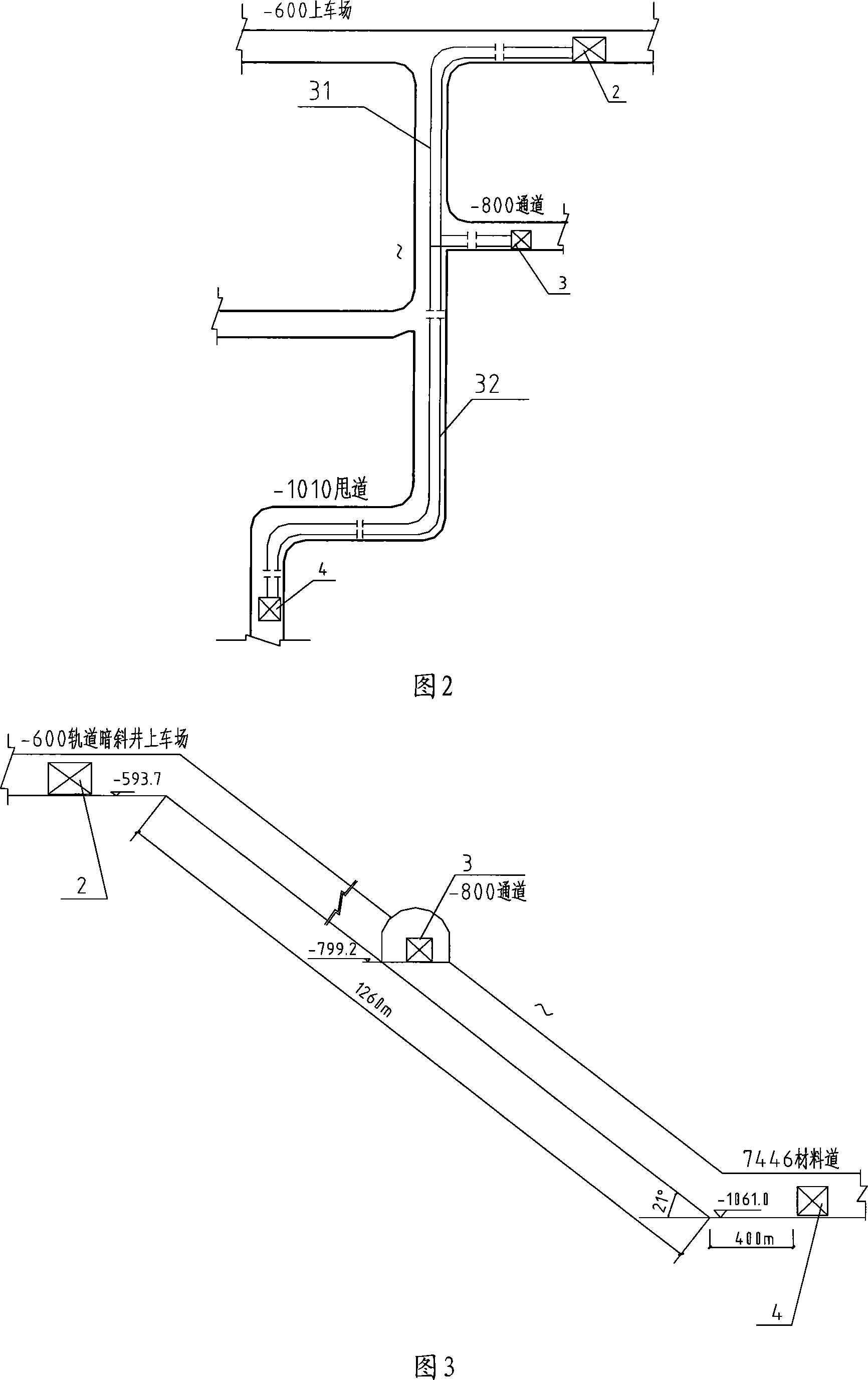

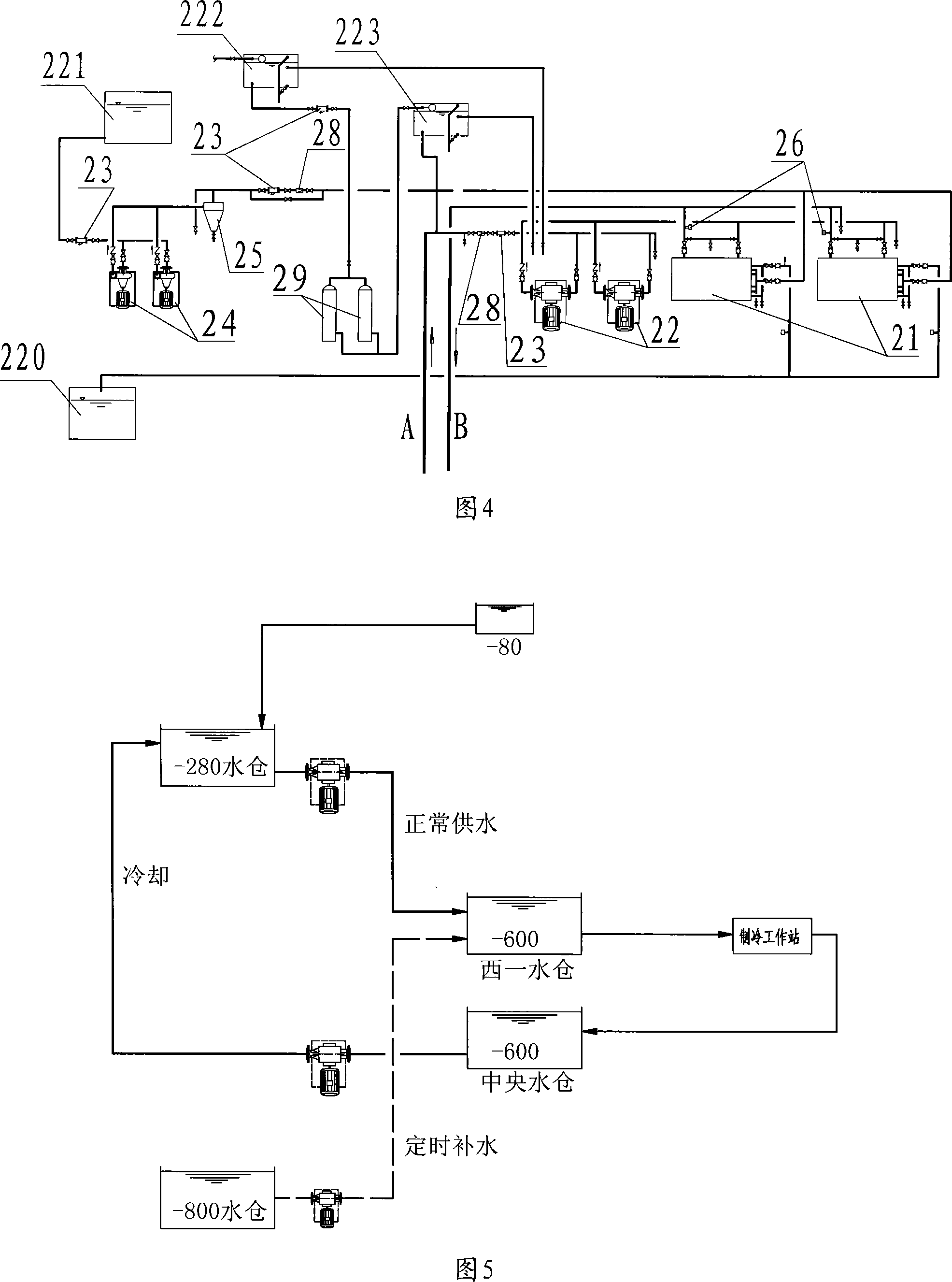

[0033] As shown in Figure 1, this embodiment provides a mine heat energy conversion cycle production system, which is mainly used for the control of heat damage in deep wells and the conversion and utilization of heat energy. The system specifically includes:

[0034] Refrigeration workstation 2, pressure conversion workstation 3, cooling workstation 4, ground workstation 7 and mine water inrush system 1; the cooling capacity extraction end of refrigeration workstation 2 is connected to the drain end of mine water inrush system 1, and the cooling water return end of refrigeration workstation 2 passes through The pump station 6 is connected to the ground workstation 7, the chilled water supply pipe and the chilled water return pipe of the refrigeration workstation 2 are connected to the pressure conversion workstation 3 to form an upper circulation subsystem, and the chilled water output pipe and the chilled water return pipe of the pressure conversion workstation 3 are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com