Acentric timing and speed-stabilized motor

A technology of stable speed and motor shaft, which is applied in the direction of motor control, electrical components, control systems, etc., can solve the problems of inability to use motor speed regulation and small control current, and achieve the effect of easy production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

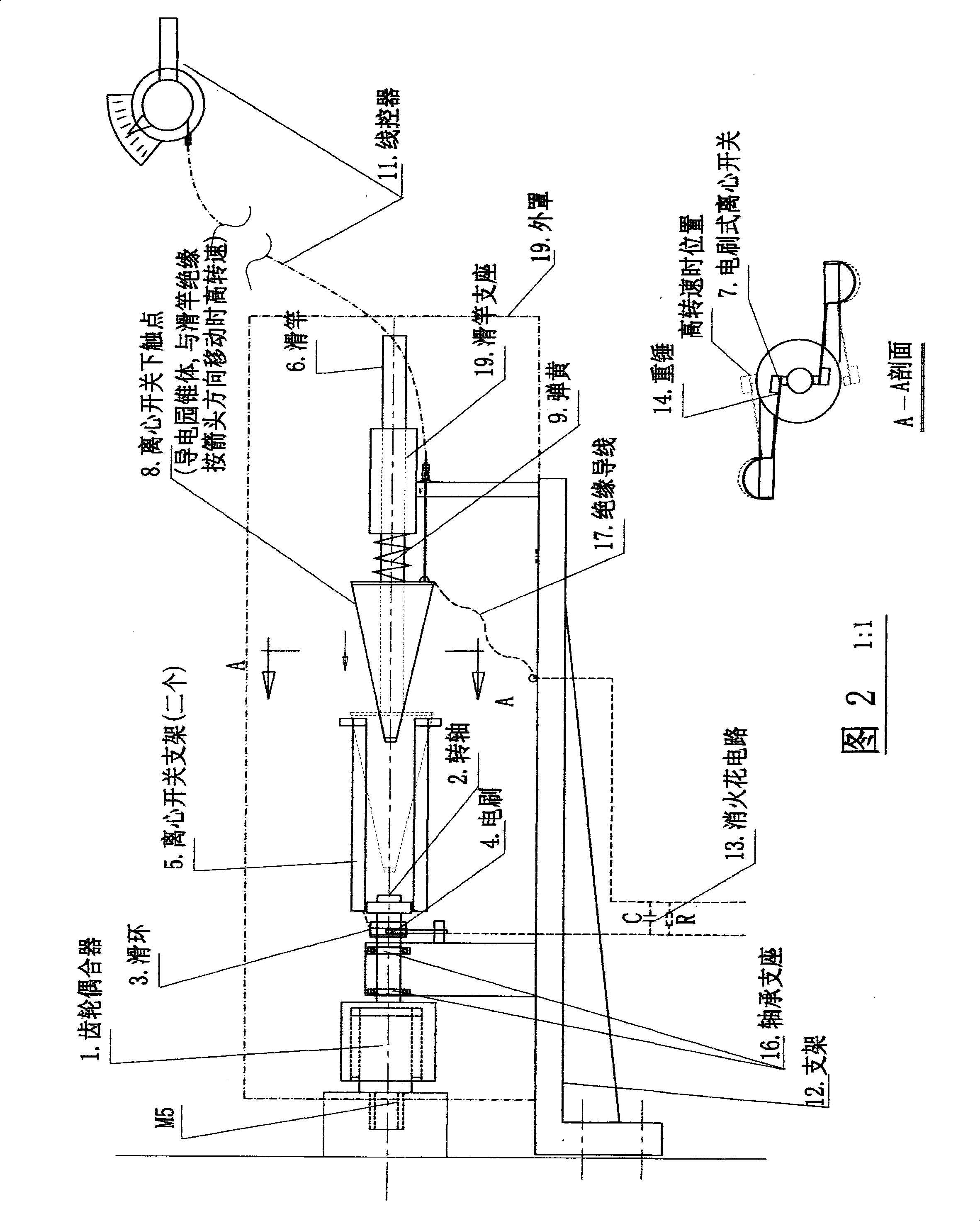

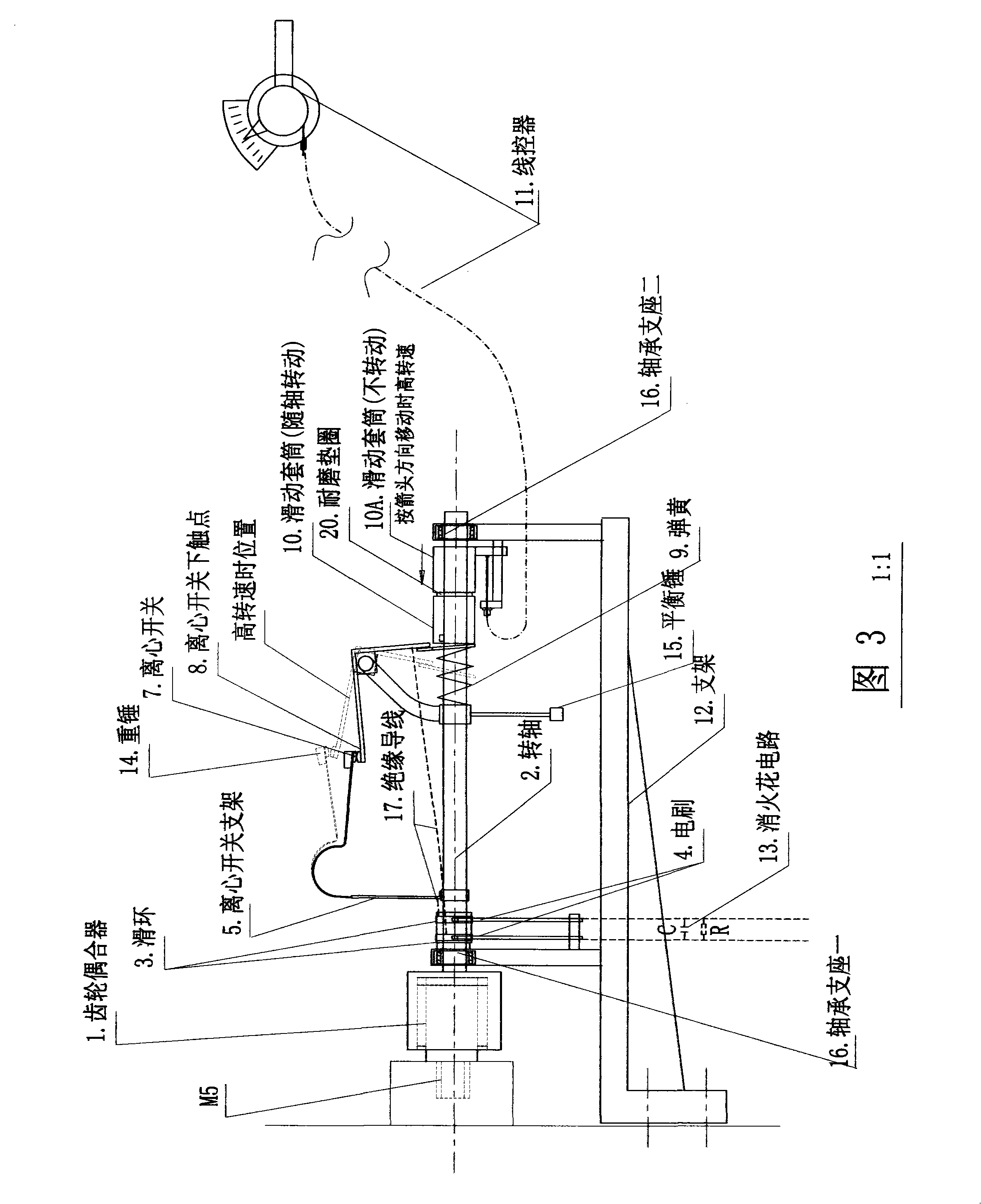

[0019] In Figure 1, the centrifugal speed governor (circle part) is mounted on the end shaft of the motor. The power enters the motor after being controlled by a centrifugal switch. (for small motors) See Figure 3 and Figure 2 for the description of each component in the figure.

[0020] Fig. 2 is an enlarged view of the first embodiment of the centrifugal governor. In the figure, the inner gear of the gear coupler 1 is fixed on the motor shaft with M5 screws, the outer gear of the gear coupler 1 and the centrifugal switch shaft 2 are fixed on the bracket 12 with the bearing support 16, and the bracket 16 is fixed on the motor casing. The power supply is connected to the brush type centrifugal switch 7 through the brush 4, the slip ring 3 and the centrifugal switch bracket 5, and the brush type centrifugal switch 7 is driven to rotate through the gear coupler 1 when the motor rotates. The lower contact 8 of the centrifugal switch is a non-rotating conductive cone, which is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com