Embedded leakage detector

A leak detector and embedded technology, which is applied in the direction of measuring the rate of increase and deceleration of the fluid, and using the liquid/vacuum degree to measure the liquid tightness, etc., can solve the problems of low measurement accuracy and leak detection reliability, and achieve improvement Detection accuracy, convenient operation, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

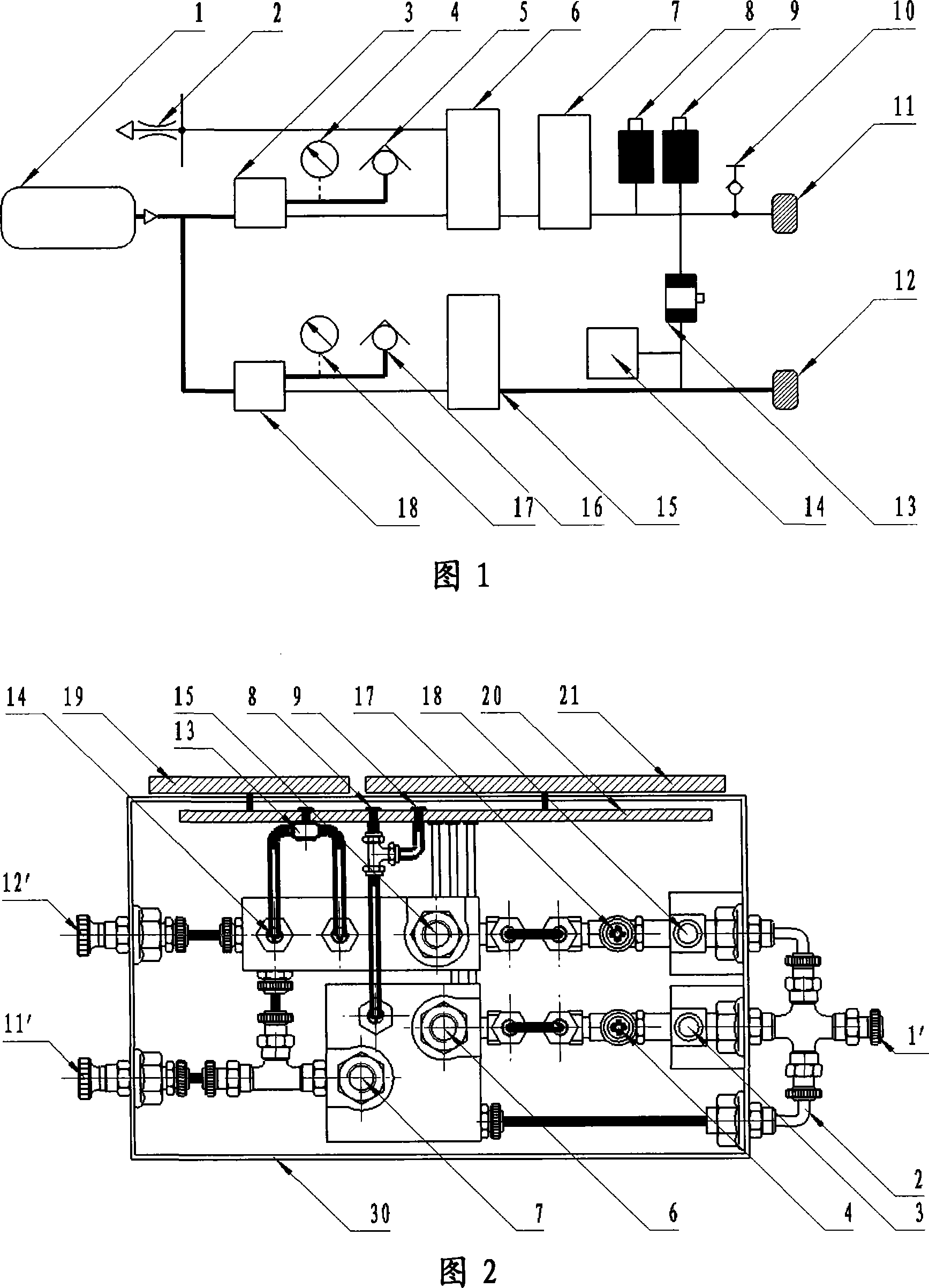

[0017] A preferred embodiment of the present invention is: see Fig. 1 and Fig. 2. The embedded leak detector includes an air source connector 1' for connecting the air source 1, a pressure regulator 3, a two-position three-way solenoid valve 6, a two-position two-way solenoid valve 7, and a detection device for connecting the detection piece 11. The direct pressure method detection pneumatic control circuit composed of the component joint 11'; the above-mentioned direct pressure method circuit and the pressure regulator 18, the two-position two-way solenoid valve 15, the pressure switch 14, and the reference component form the differential pressure method detection pneumatic control circuit. The pressure gauge 4 shows the value of the pressure regulator 3, the exhaust port 5 and the exhaust port 10 play a pressure limiting role, the pressure gauge 17 shows the value of the pressure regulator 18, and the exhaust port 16 plays a pressure limiting role. Vent 2 discharges the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com