Flying shear for shearing corrugated plate

A technology of corrugated plates and flying shears, which is applied in the direction of knives for shearing machine devices, devices for shearing forming blanks, shearing devices, etc., and can solve the unsuitable requirements for shearing and sizing of corrugated plates, and the end face of corrugated plates. Not vertical, can only cut flat plates and other problems, to achieve the effect of solving uneven cross-cutting sections, easy operation, and accurate precision control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

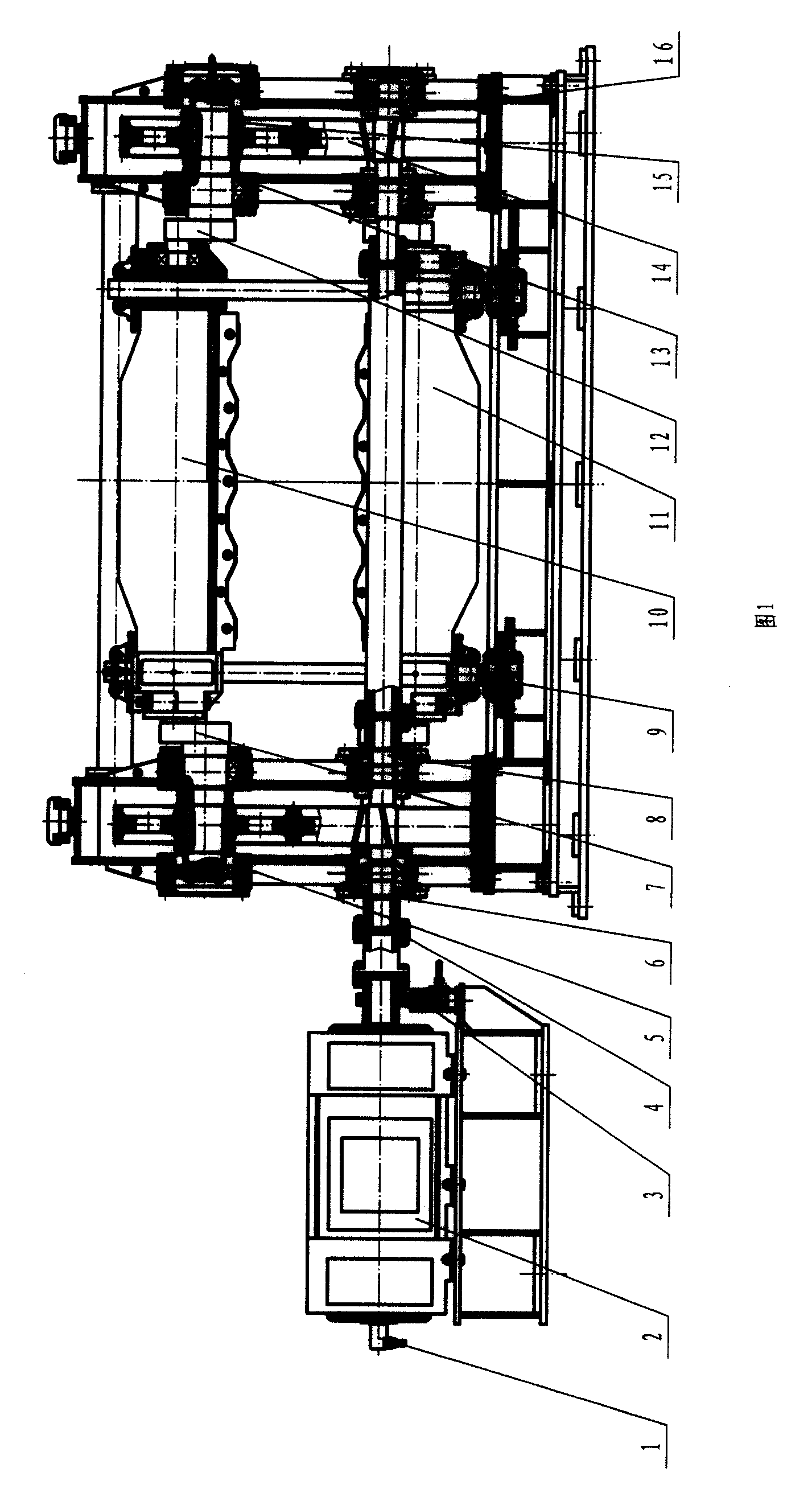

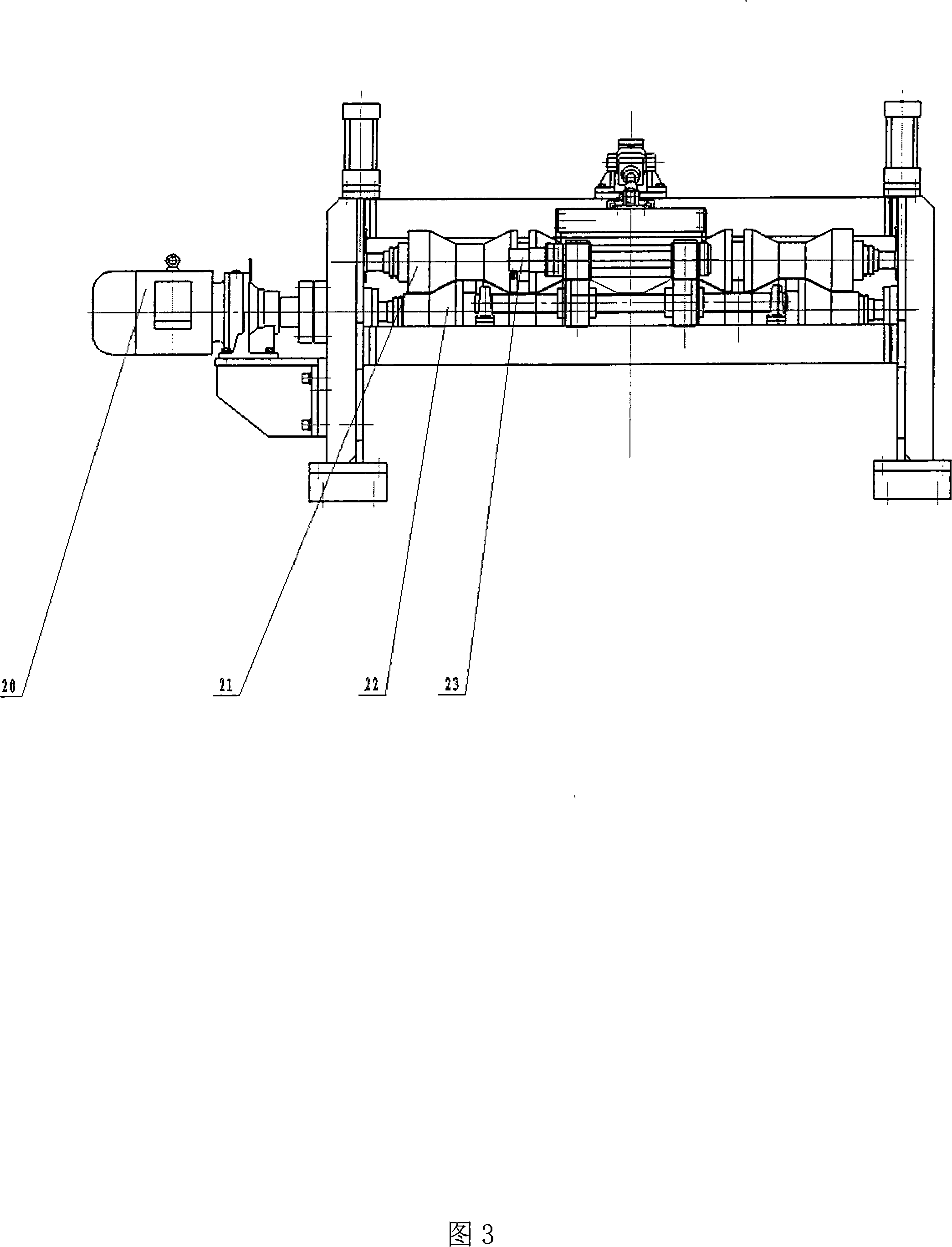

[0020] Specific embodiment: In Fig. 1, including the electrical control system, the equipment is driven by the servo motor 2 through the two-way coupling 4, the left gear shaft 8, and the right-handed large gear 14 and the left-handed large gear 15 of the left transmission box 5 are up and down and left. crankshaft 7, and the upper and lower left crankshafts 7 are connected with the upper shearing device 10 and the lower shearing device 11 through bearings; 15, the upper and lower right crankshaft 12, and the upper and lower right crankshaft 12 are connected with the upper shearing device 10 and the lower shearing device 11 through bearings; The axis rotation of the gear 15 slides up and down along the guide rod device 9 through the guide sleeve again, and the guide rod device 9 moves along the guide plate on the base, and the moment of shearing, the guide rod device 9 is in a vertical position.

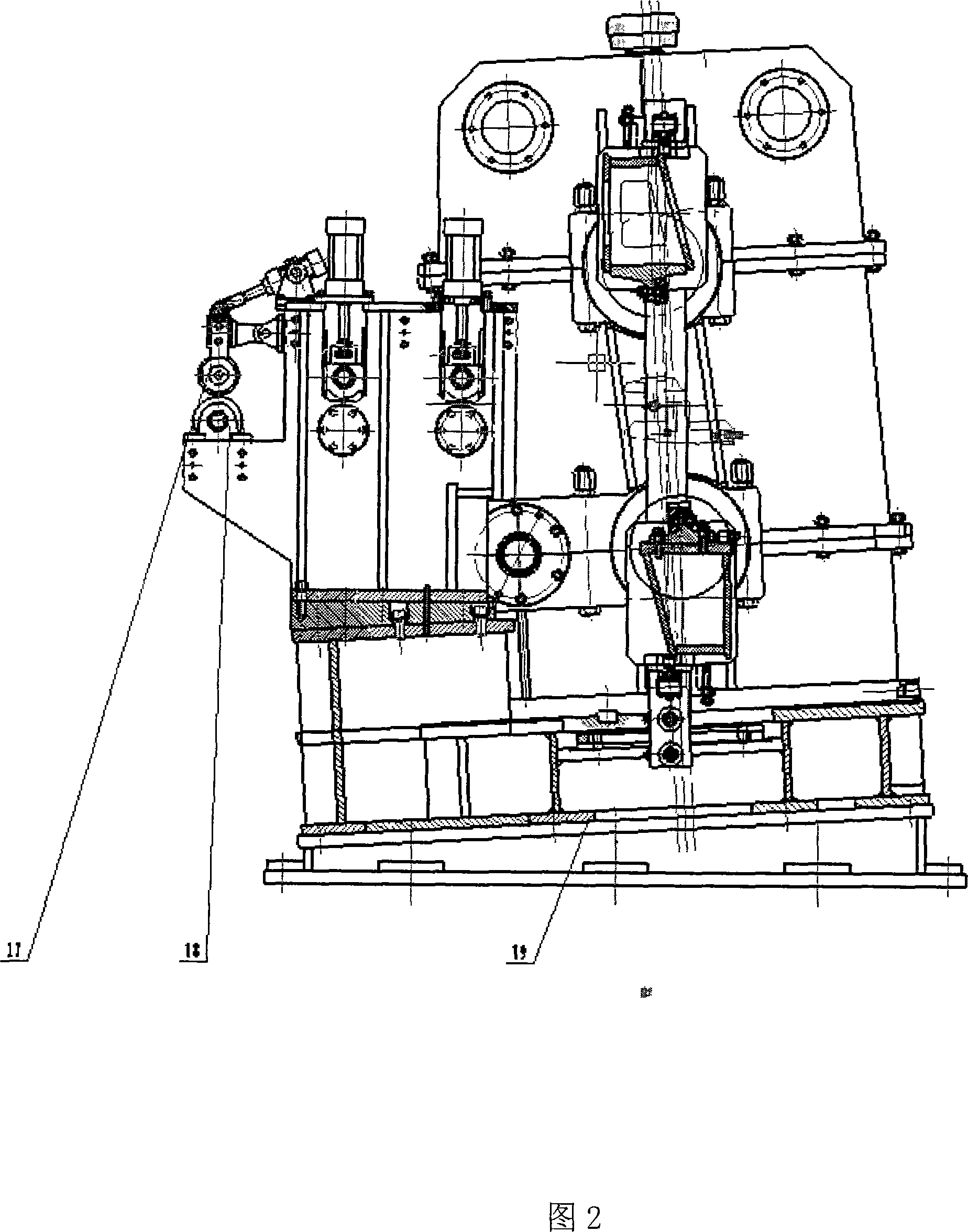

[0021] The upper blade 28 and the lower blade 29 are fixed on the upper and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com