Technique and equipment for preparing tea beverage

A process equipment and tea beverage technology, applied in the field of filtration process and equipment, can solve the problems of centrifugal device investment cost, high maintenance cost, centrifugal device production efficiency, low output, impurity can not be removed, etc. Easy to replace and improve filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

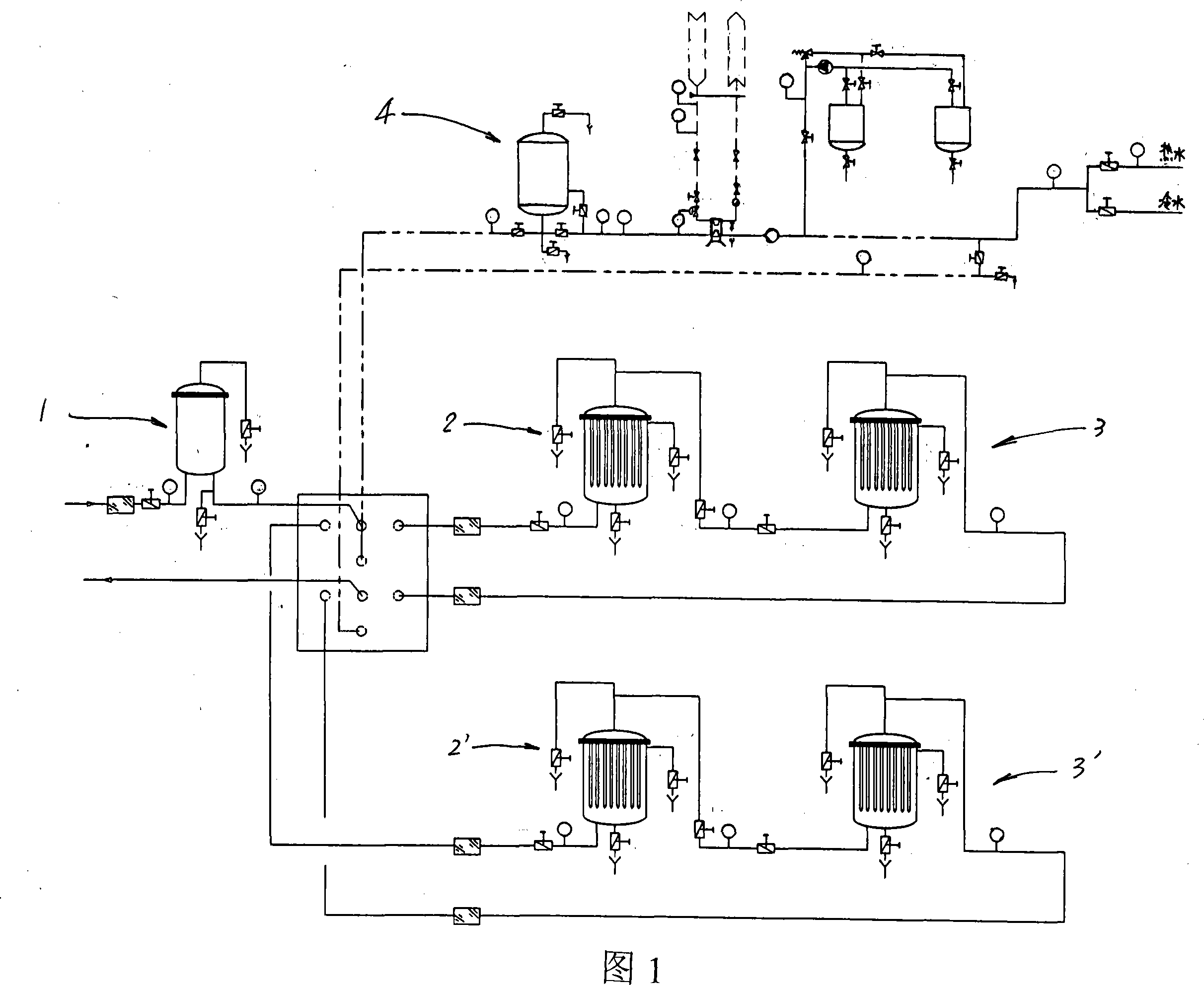

[0046] The present invention will be further described below in conjunction with accompanying drawing.

[0047]Please refer to Figure 1, which shows the process flow diagram of the present invention, a process for preparing tea beverages, the tea raw materials are brewed in sequence to make crude products, cooled to 12-14°C, flocculated and settled for about 30 minutes, resulting in obvious separation. layer, the supernatant is filtered and formulated into a tea beverage, wherein the filtering of the supernatant includes in sequence:

[0048] Primary filtration: After flocculation and sedimentation, the supernatant enters the primary filter device 1, and the primary filter device 1 is equipped with a folded filter bag for preliminary filtration;

[0049] Secondary filtration: enter the secondary filter device 2, and the secondary filter device 2 is provided with a folded filter element 5 for pre-filtration to obtain preliminary clarified liquid;

[0050] Three-stage filtratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com