Process for treating an imaged printing form

A printing plate and imaging technology, which is applied in the field of processing the imaged printing plate, to achieve the effect of improving contrast, simple device, and reducing waste pages when starting up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

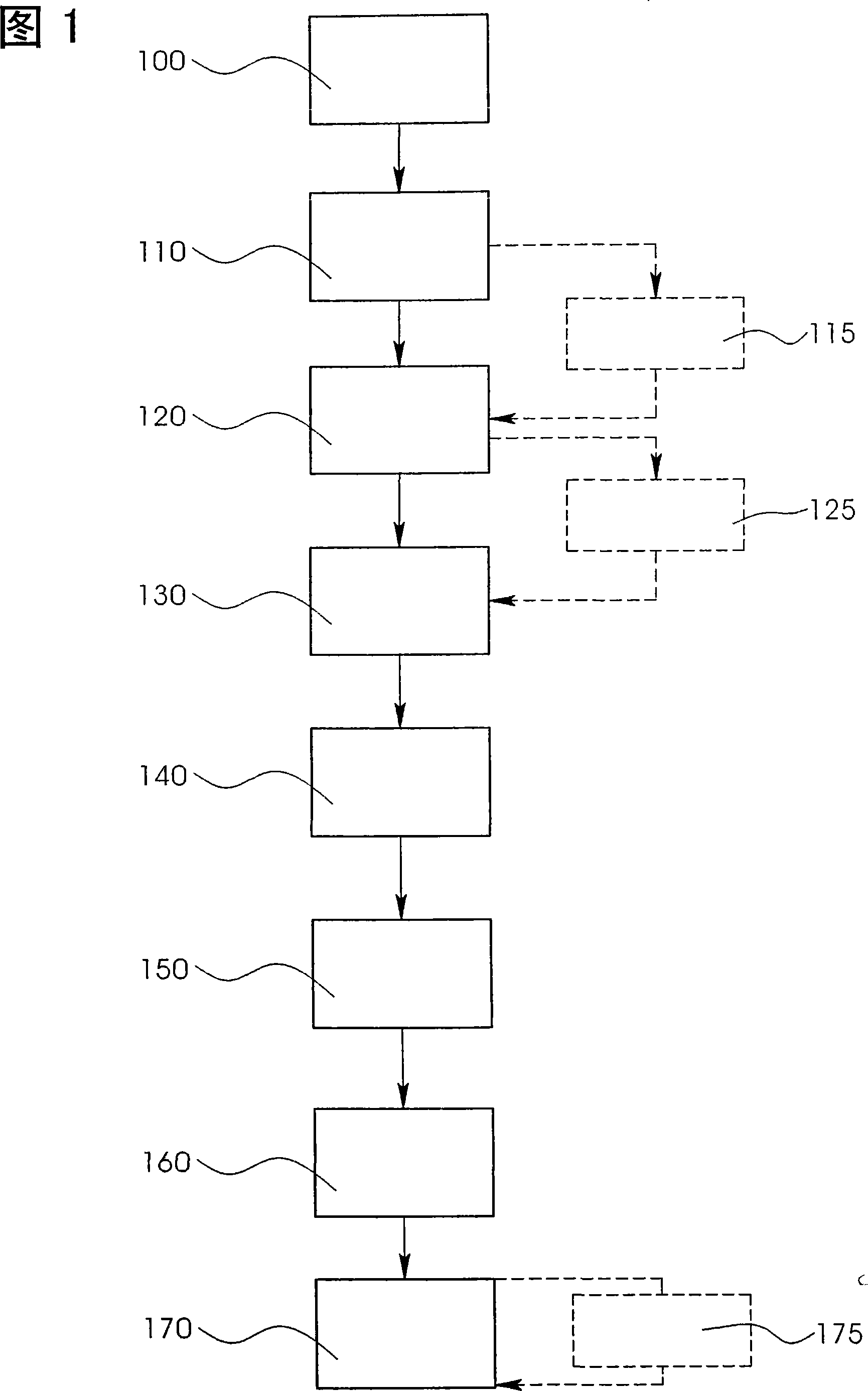

[0036] figure 1A flow chart of a preferred embodiment of the method according to the invention for processing imaged printing plates is shown. Such a printing form can, for example, contain or consist of titanium dioxide and be arranged on a carrier, for example metal or plastic. The printing form is preferably configured as a lithographic printing form for lithographic offset printing. The method according to the invention can not only be used in machines for processing printing materials, especially in printing presses, but can also be used at least partially, ie at least several method steps such as initialization, covering, imaging, gluing and / or removal in such Implemented externally to the machine.

[0037] In method step 100 (initialization), the rough-cleaned or selectively fine-cleaned (see method step 170 below) surface is initialized prior to re-covering 110 with molecules by applying an initializing liquid, especially water, VE water or an aqueous priming soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com