Oscillation testing protective equipment and testing method

A technology of vibration detection and protection device, applied to measurement devices, vibration measurement in solids, measurement of vibration and other directions, can solve problems such as failure to protect the unit in time, inconvenient on-site observation, and damage to the unit, and achieve high reliability and easy installation. , improve the protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

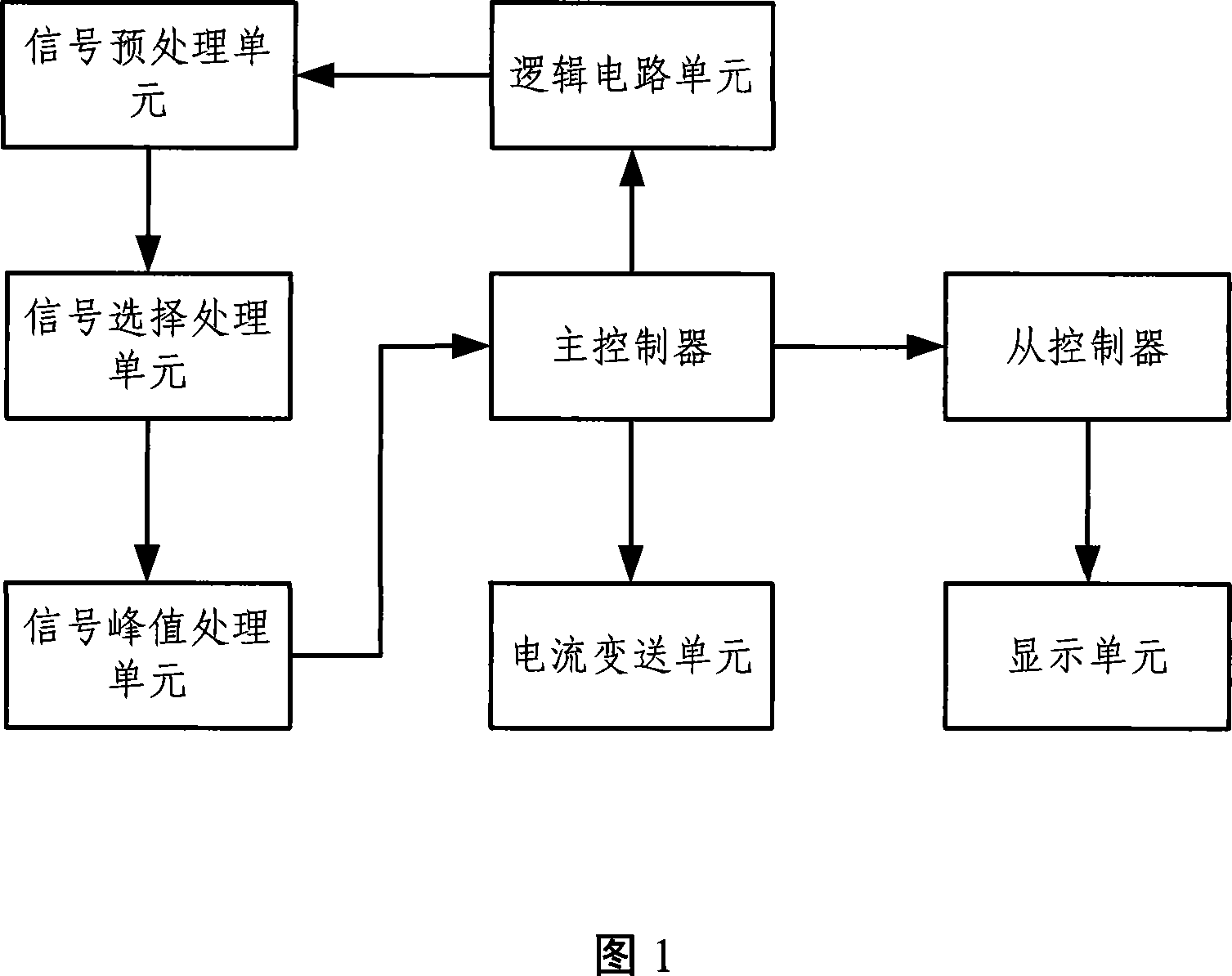

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

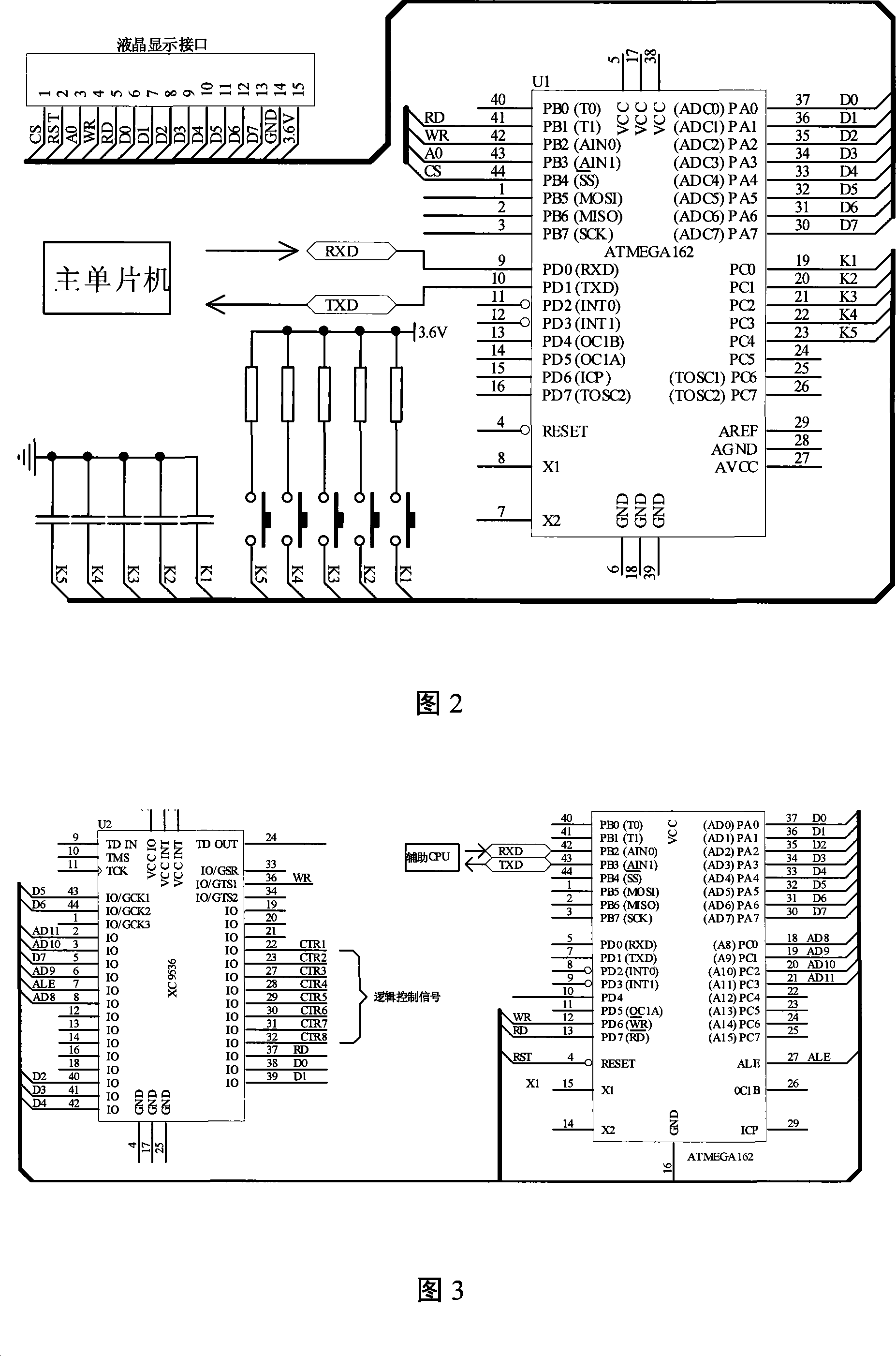

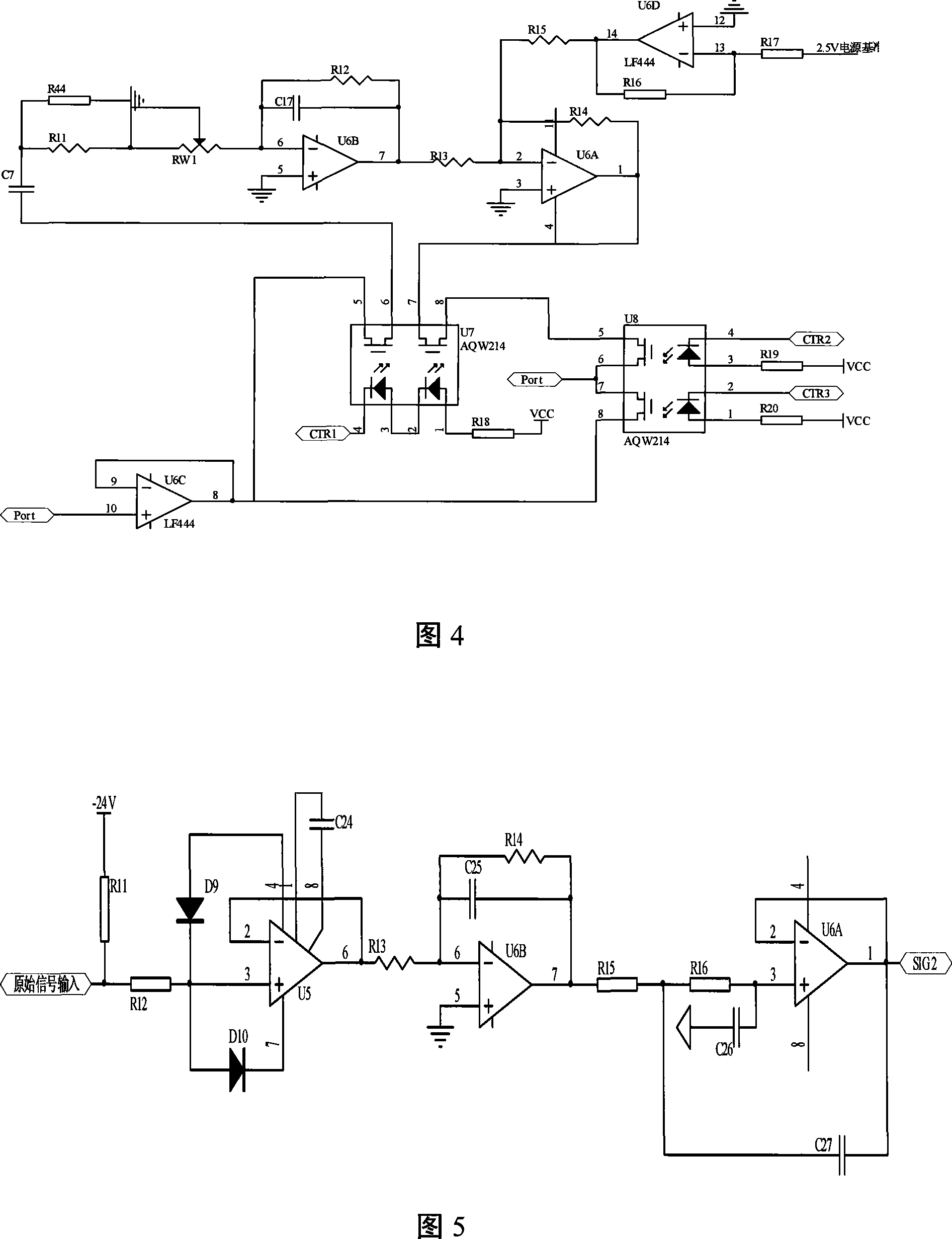

[0022] In this embodiment, the Zhu controller adopts single-chip microcomputer ATMEGA162 as the control core, and uses the programmable logic chip XC9536 as the logic control component. The on-site vibration value display can realize the on-site liquid crystal display of vibration data, and the data prompt and parameter setting process are prompted in Chinese. The setup process is intuitive and straightforward. At the same time, the vibration alarm threshold, alarm delay time, etc. are set on site. When the monitoring value exceeds the alarm setting range, an alarm or trip signal is given to directly protect the unit.

[0023] Fig. 1 is a schematic structural diagram of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com