Lens barrel and imaging apparatus including the same

A technology of lens barrel and lens group, which is applied in installation, instrumentation, optics, etc., can solve the problems of complex component structure and increase of lens barrel size, and achieve the effect of simplifying structure and reducing lens barrel size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

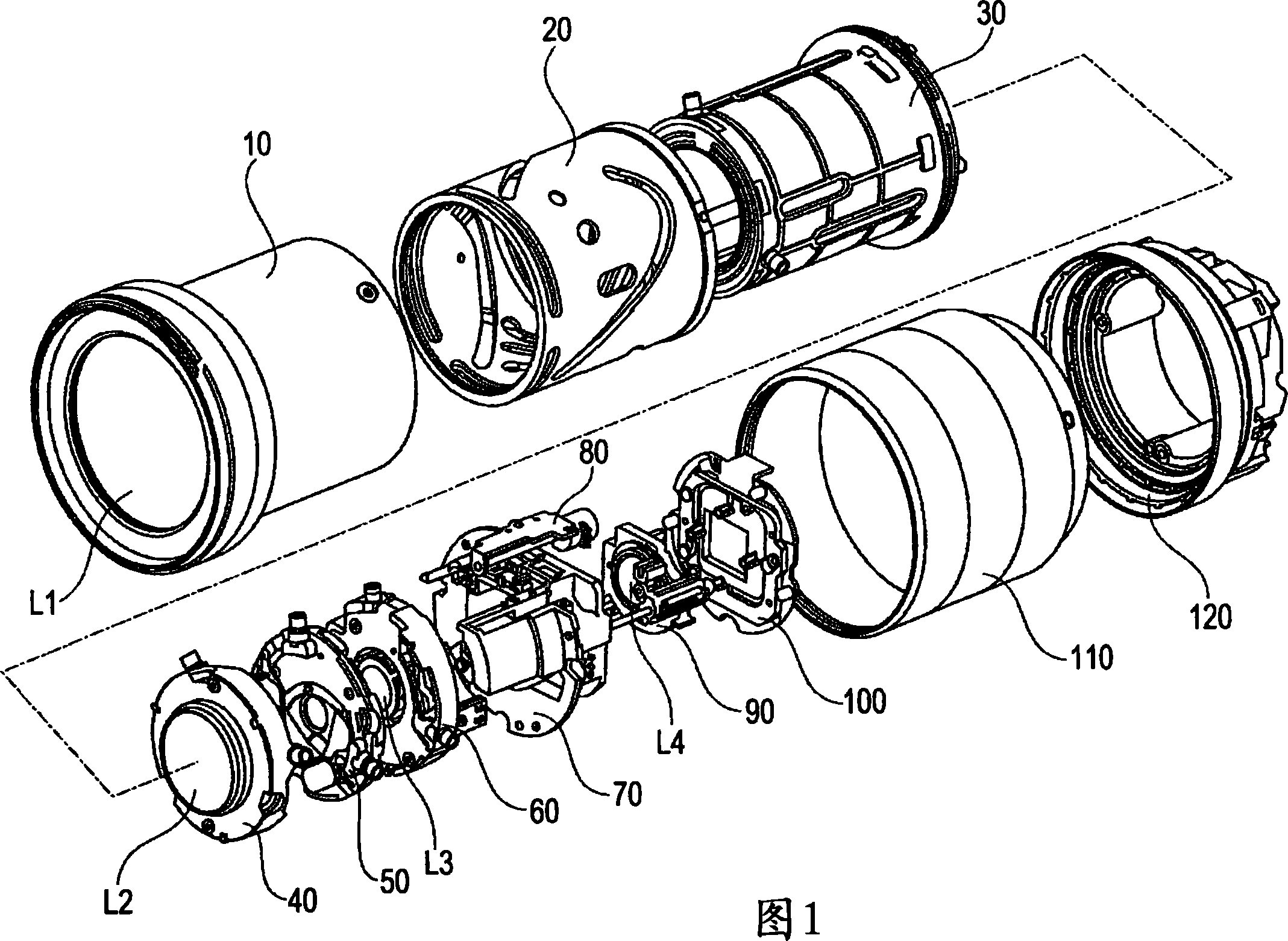

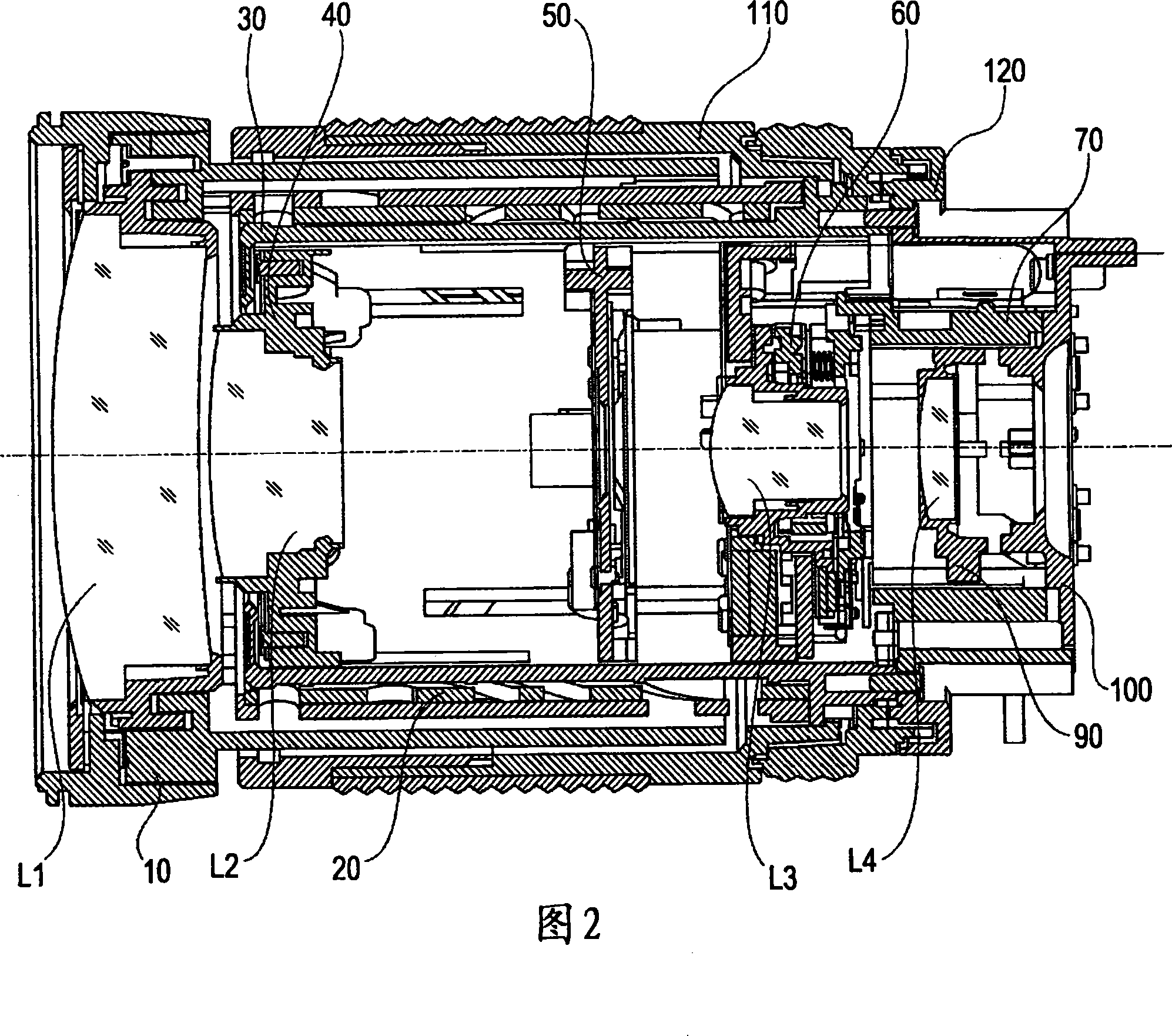

[0027] FIG. 1 is an exploded perspective view showing the structure of a lens barrel used in imaging devices such as video cameras and digital cameras, which is applicable to the present embodiment. 2 and 3 are optical cross-sectional views showing the structure of a lens barrel in an imaging device such as a video camera and a digital camera, which is applicable to the present embodiment. Figure 2 shows the state of each lens group at the wide-angle position. Figure 3 shows the state of each lens group at the telephoto position.

[0028] A lens barrel according to an embodiment of the present invention includes four lens groups. In FIG. 1, lens groups L1, L2, and L3 have a zoom function; L1 is a first zoom lens group, L2 is a second zoom lens group, and L3 is a third zoom lens group. The third zoom lens group L3 moves in a direction substantially perpendicular to the optical axis to optically correct blurred images. The third zoom lens group L3 corresponds to the first len...

no. 2 Embodiment

[0061] 8 and 9 are schematic diagrams showing an improvement in which the tension spring 93 as the urging member in the lens barrel of the first embodiment is replaced with a compression spring 98 .

[0062] The structure of the lens barrel used in imaging devices such as camcorders and digital cameras applicable to the second embodiment, and the overall structure of the focusing lens unit are basically the same as those of the first embodiment, and thus will not be described again here.

[0063] FIG. 8 shows a state in which the focus lens holding member 91 and the image blur optical correction unit 60 are independently driven without interfering with each other. FIG. 9 shows a state in which the focus lens holding member 91 and the image blur optical correction unit 60 interfere with each other.

[0064] The image blur optical correction unit 60 holds the third zoom lens group L3. The focus lens holding member 91 holds the focus lens group L4. The focus lens holding member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com