Device for testing elastic foil tablet transverse bearing departure rotary speed

A technology of radial bearings and elastic foils, which is applied in the field of devices for testing the take-off speed of elastic foil radial bearings, and can solve the problem of not giving the take-off speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

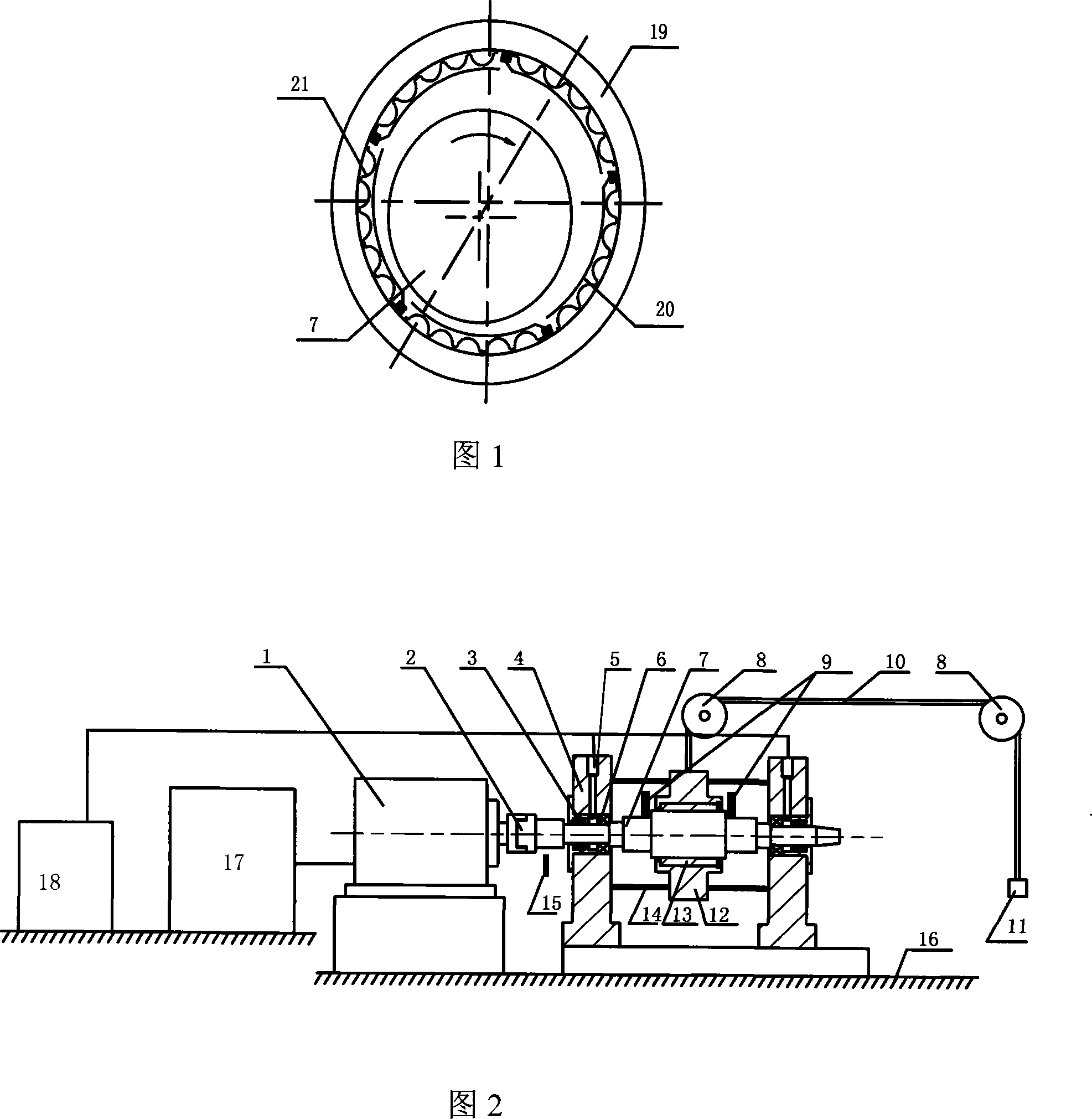

[0015] Referring to Fig. 1, the structure of the tested radial bearing 13 is as follows: including the test bearing housing 19 and the bearing foil 22, the bearing foil 22 is composed of five top layer foils 20 and arch corrugated foils 21, and the five top layer foils 20 One end of the arched wave foil 21 is welded on the test bearing seat 19 and evenly distributed along the inner wall surface of the test bearing seat 19, and the other end is free. The smooth top layer foil 20 forms an arc surface under the action of pre-tightening force, The working surface of the bearing is provided, and the arched corrugated foil 21 provides elastic support for the top foil 20, and the journal 7 rotates in the direction from the welding end to the free end during operation.

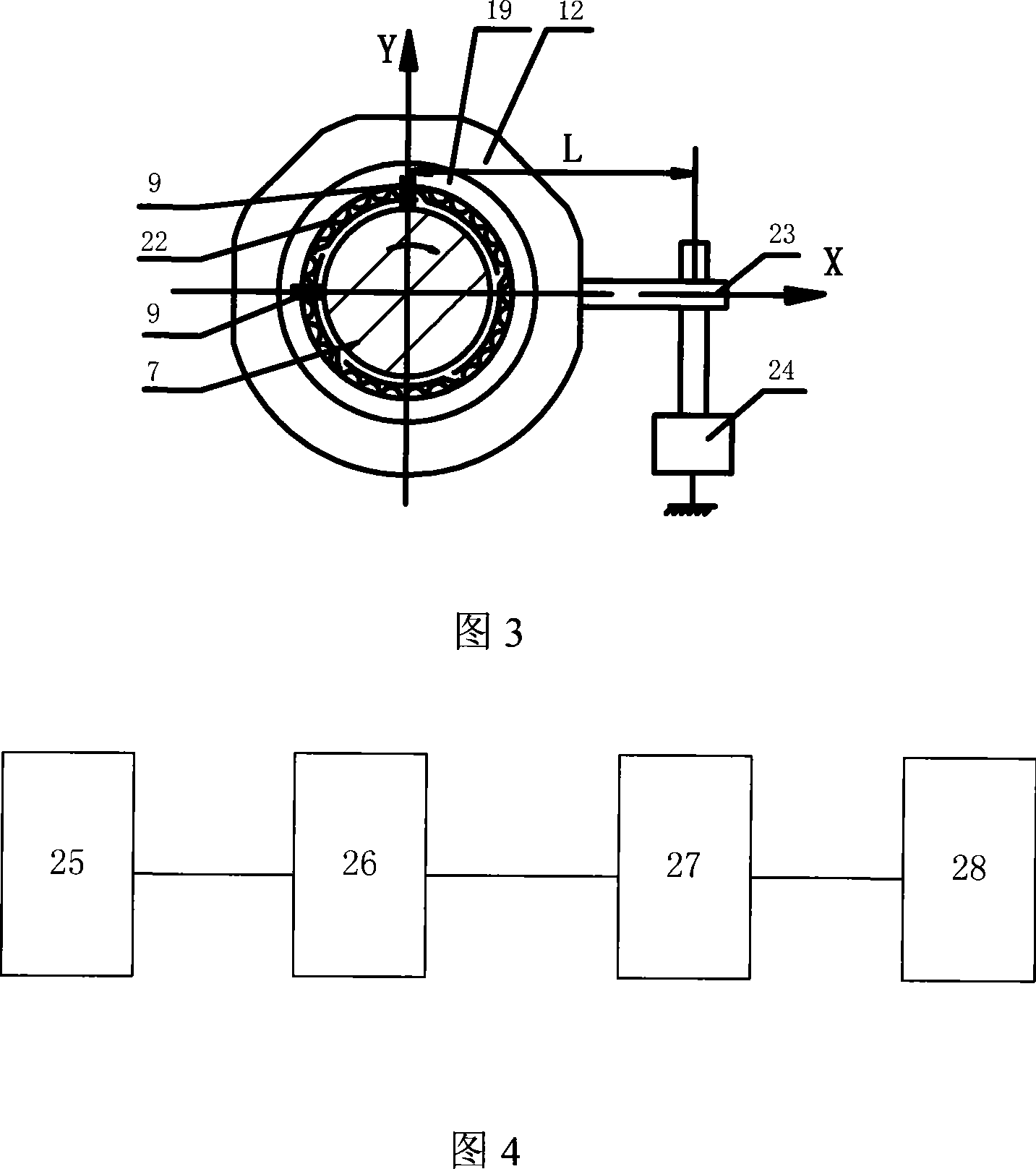

[0016] Referring to Fig. 2, Fig. 3 and Fig. 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com