Parallel mechanism capable of realizing interconversion between 3D translation and 3D rotation

A three-dimensional rotation, three-dimensional translation technology, applied in the field of manufacturing, can solve the problem of rare parallel mechanism, and achieve the effect of simple structure and flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

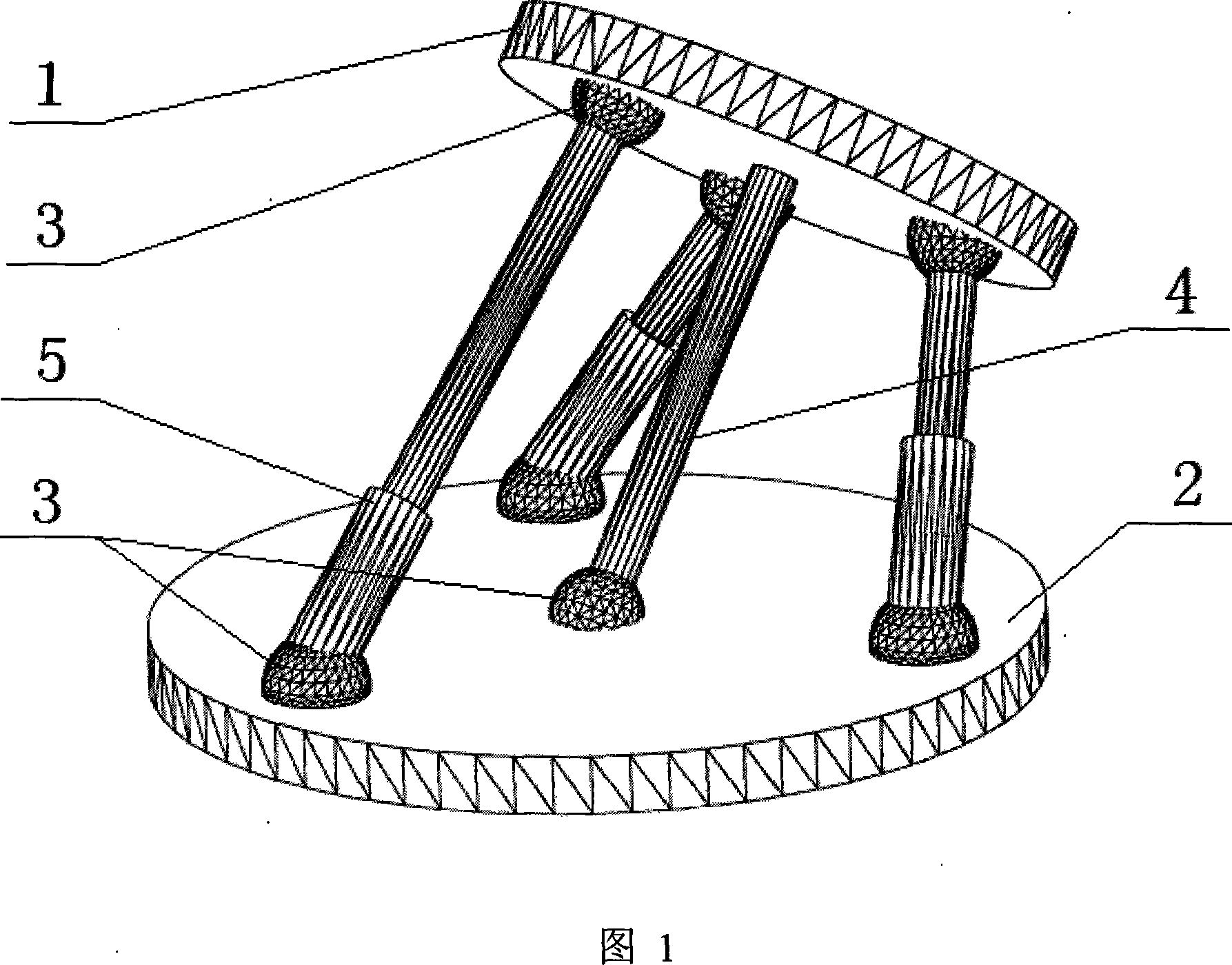

[0013] In the embodiment shown in Fig. 1: it includes a moving platform 1, a fixed platform 2 and four branch chains, one of which is a branch whose top end is fixedly connected to the moving platform 1, and the other end is connected to the fixed platform 2 through a ball joint 3. Rod 4, all the other three branch chains contain a telescopic rod 5, and the two ends of the telescopic rod 5 are respectively connected with the moving platform 1 and the fixed platform 2 through the ball joint 3.

[0014] If the two ends of the telescopic rod 5 are respectively connected to the moving platform 1 and the fixed platform 2 to form an equilateral triangle, and the spherical hinge 3 connecting the strut 4 to the fixed platform 2 is located at the center of the equilateral triangle, then the performance of the mechanism will be better. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com