Easy squeeze blind rivet gun

A technology of riveting guns and pull rods, applied in the field of devices using rivets, can solve problems such as low production efficiency, physical fatigue, noise pollution, etc., and achieve the effects of compact structure, strong output, and avoiding hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

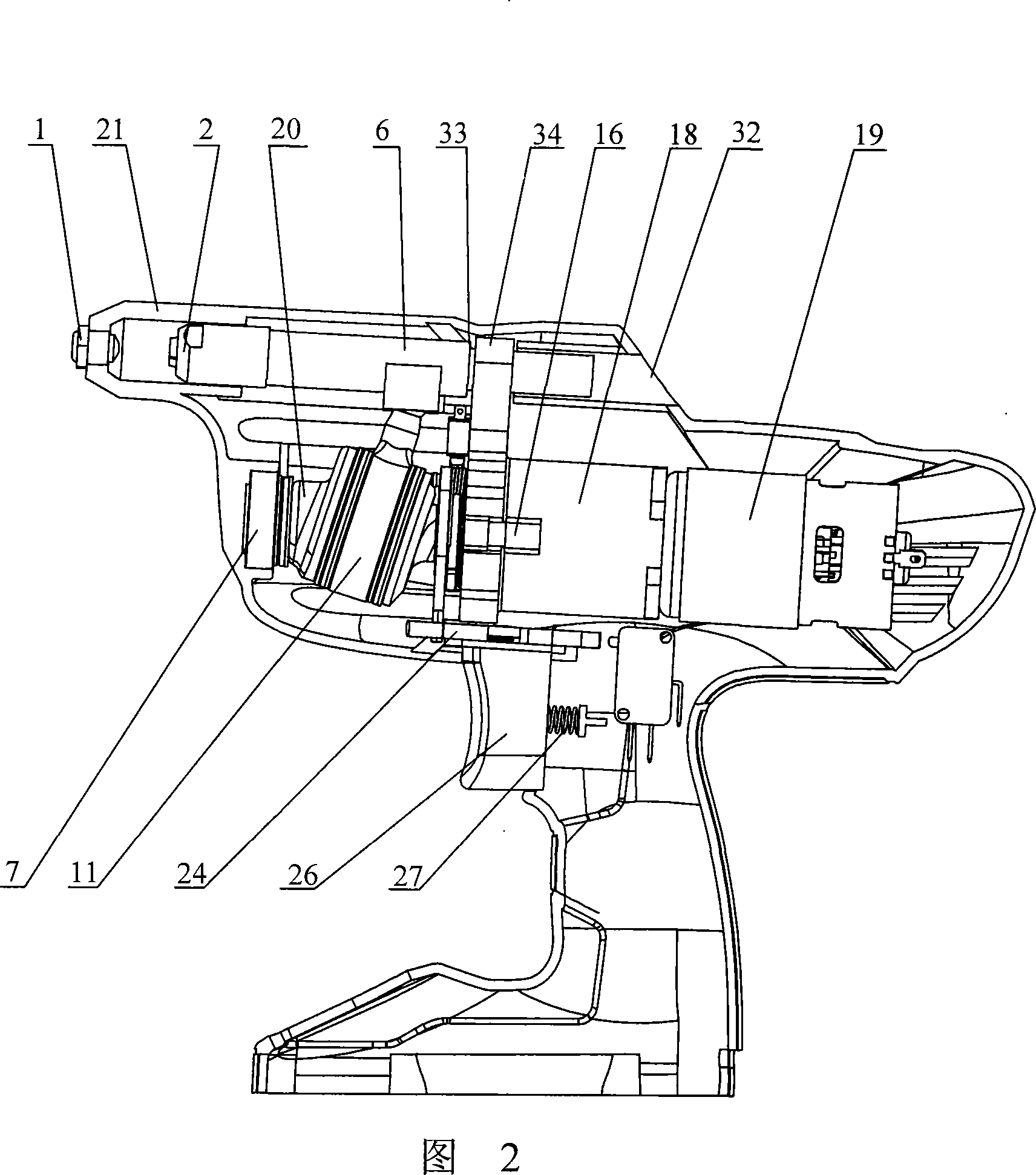

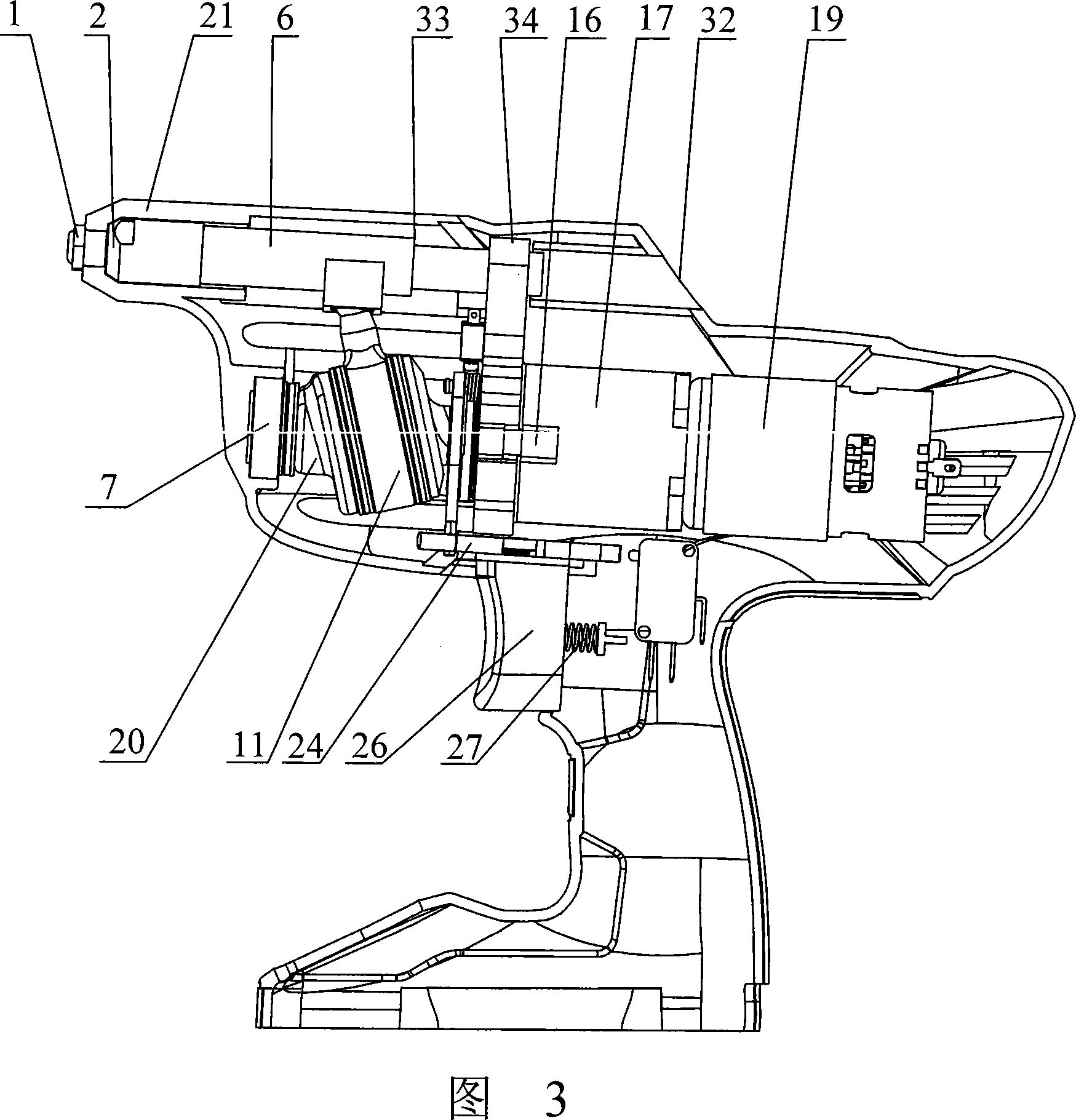

[0020] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0021] As shown in the figure: a nail mouth 1 is fixedly installed in the shell 21, and a through hole 28 for inserting a rivet is opened on the nail mouth 1, and a riveting device is slidably connected in the shell 21 on one side of the nail mouth 1. The sliding direction of the riveting device is consistent with the axial direction of the through hole 28 , and a driving device and a control device for driving the riveting device to slide back and forth relative to the nail mouth 1 are provided in the housing 21 .

[0022] The riveting device includes a claw foot fixer 3 arranged on the right side of the nail mouth 1, a claw foot 2 is arranged in the claw foot fixer 3, and a claw foot that is in contact with the right end surface of the claw foot 2 is provided on the right side for pressing 4, the claw foot presser 4 is arranged in the mounting hole 29 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com