Cooling rib direct driven permanent magnetic synchronous single bearing aerogenerator

A wind turbine and permanent magnet synchronous technology, applied to synchronous motors with stationary armatures and rotating magnets, electrical components, electromechanical devices, etc., can solve the inconvenience of transportation and hoisting, low motor performance indicators, and unpredictable temperature rise and other problems, to achieve the effect of compact structure, good protection effect, increased reliability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

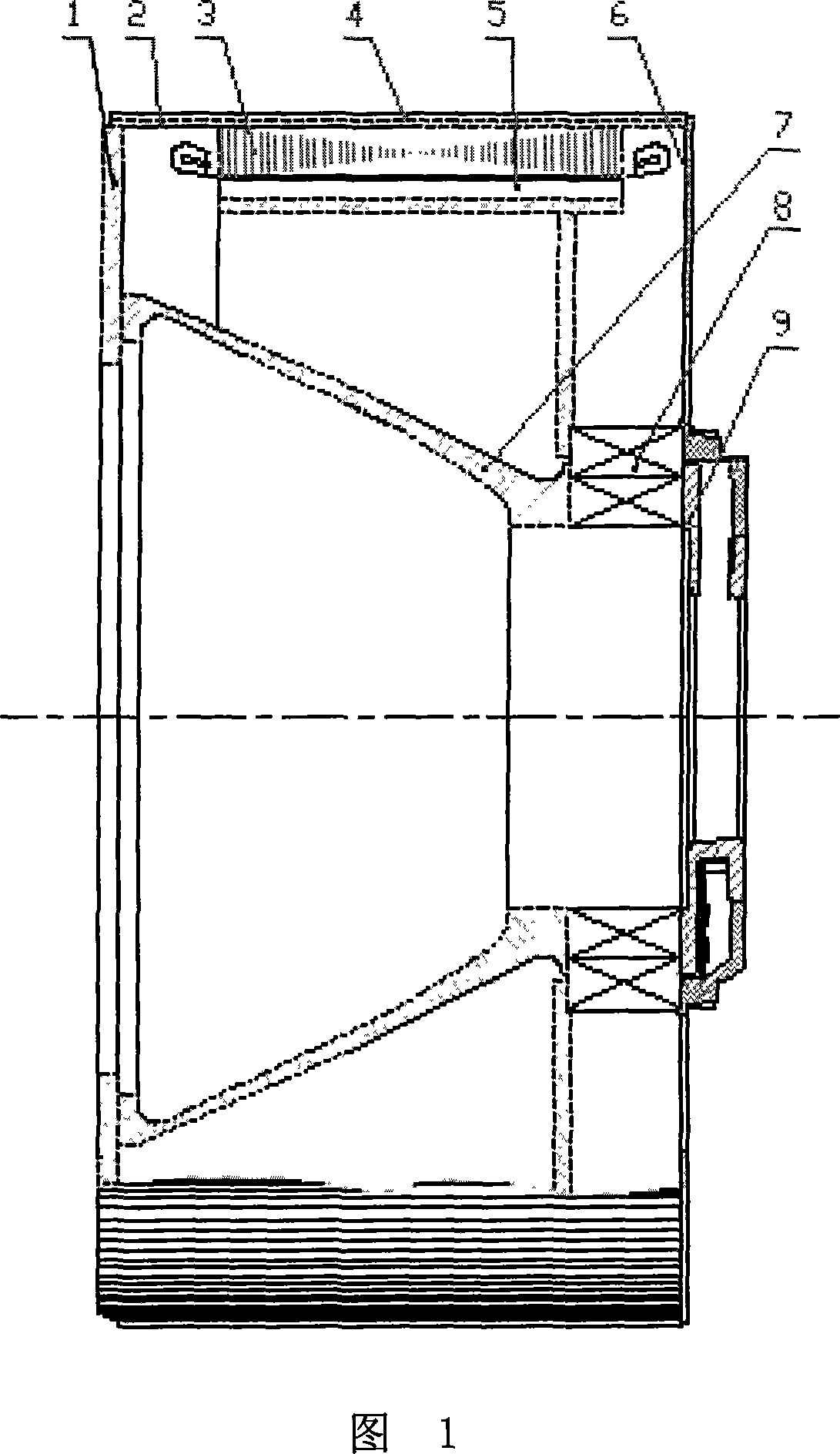

[0008] Referring to the accompanying drawings, this embodiment includes an end plate 1, a frame 2, a stator 3, a rotor 5, and an end cover 6. 5 is composed of two concentric cylinders, and windings and permanent magnets are respectively provided on their two opposite surfaces. The stator 3 is fixed in the frame 2, and the rotor 5 rotating relative to the stator 3 is fastened to the outer ring of the bearing 8 Above, the inner ring of the bearing 8 is connected to the conical support 7, the conical support 7 is connected to the end plate 1, and the side of the bearing 8 located on the hub side of the fan is connected to a brake 9.

[0009] Before the present invention is connected with the nacelle and the fan hub, it can be assembled separately into a whole. First, the stator 3 and the base 2 are assembled into one body, and the conical suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com