6-freedom micro-motion platform capable of isolating exterior vibration

A technology of micro-motion table and degree of freedom, applied in the field of micro-motion table, can solve the problems of large load mass, magnetic field, interference, etc., and achieve good shock absorption effect and reduce disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing:

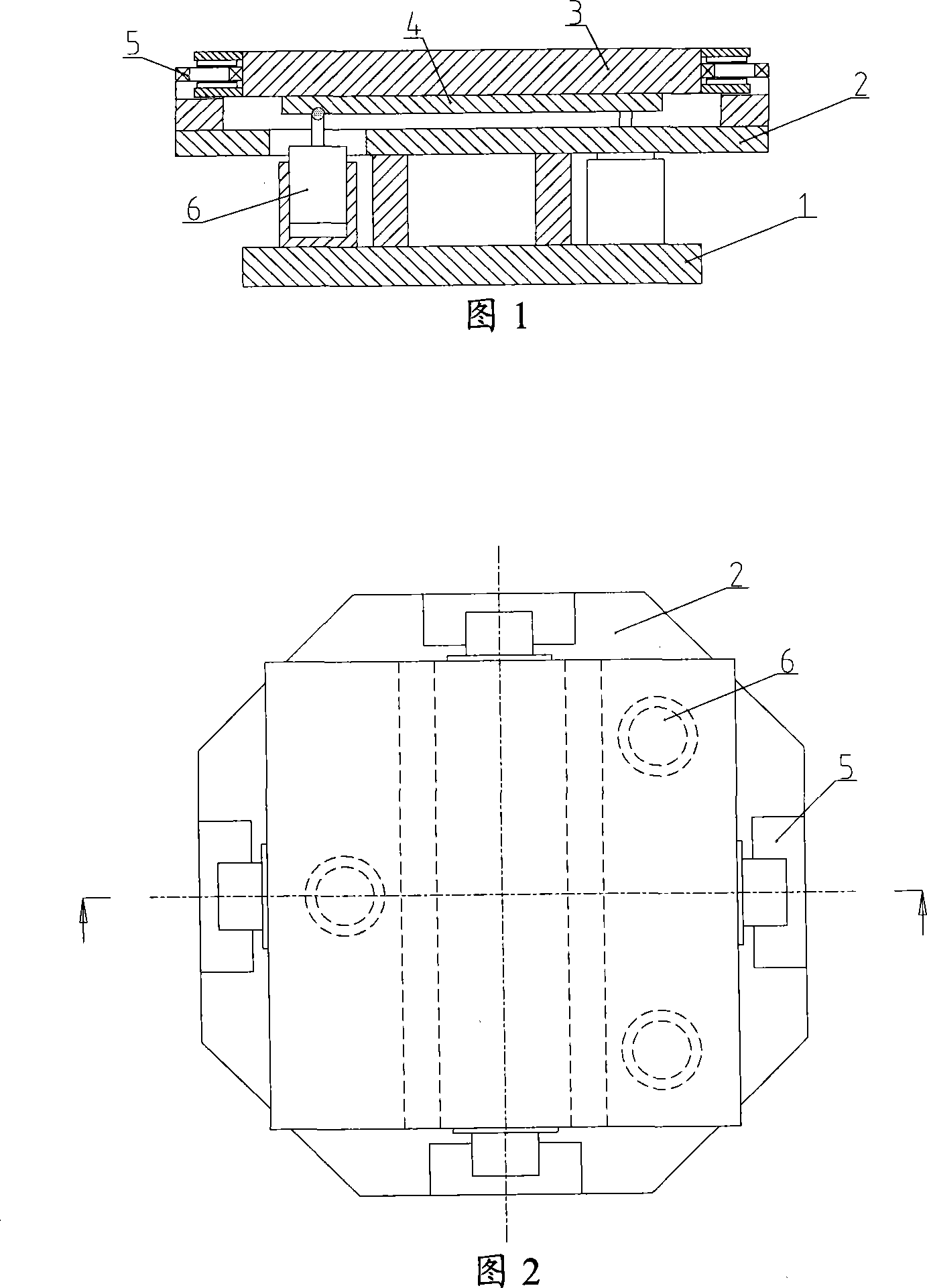

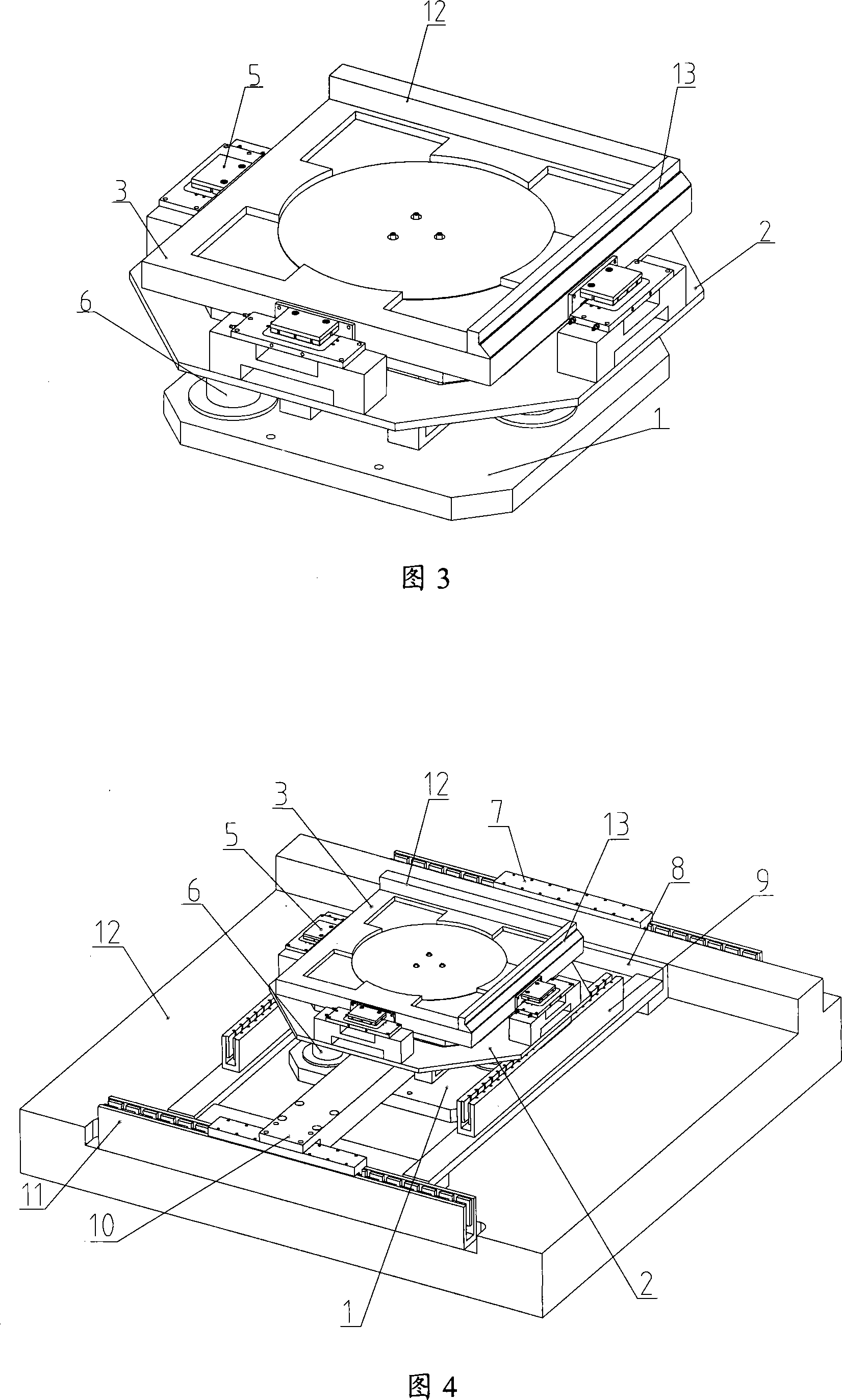

[0020] As shown in Figures 1, 2, and 3, the six-degree-of-freedom micro-motion table that can isolate external vibrations of the present invention includes an air foot 1, a motor support plate 2, a film holder 3, a leveling and focusing module 4, and a horizontal micro-motion motor 5 and gravity compensator (mini-airmount) 6. The air foot 1 is located at the bottom of the micro-motion stage, carries the entire micro-motion stage, and guides the micro-motion stage in the horizontal direction. Compared with the isolation of the entire workpiece platform by air suspension and vibration isolation in the prior art, only one air foot of the present invention carries the micro-motion stage, and the air foot 1 can isolate the vibration of the frame, reduce motion friction, eliminate the manufacturing error of the base platform, and can Prevent the shear pressure caused by the micro d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com