Side light type backlight module group

A backlight module, side-light technology, applied in the field of side-light backlight modules, can solve the problem of narrow color gamut of cold cathode lamps, achieve good flexibility, increase the color gamut range, and improve the use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

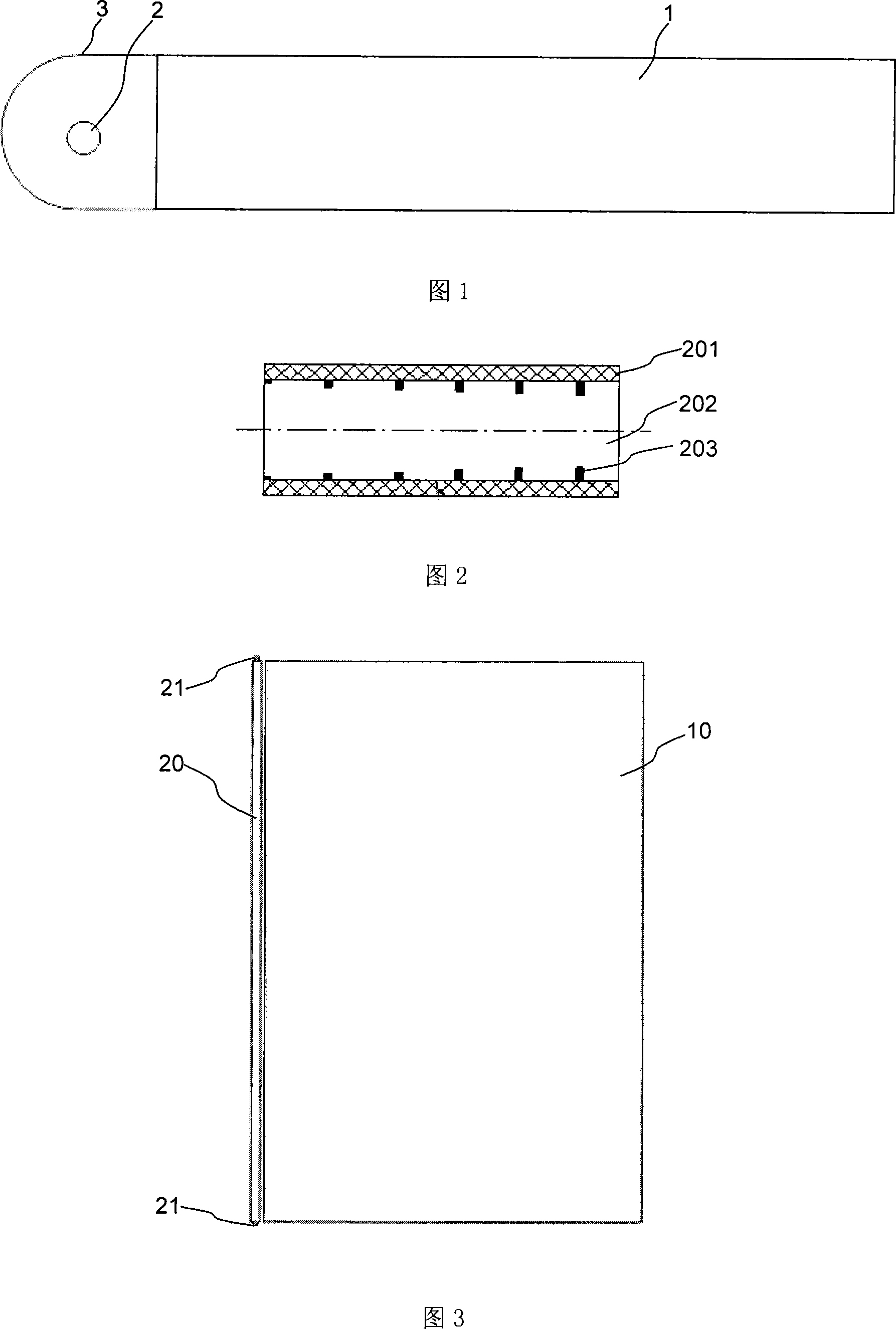

[0014] Fig. 2 is a schematic structural view of a whole-body light-emitting fiber, which is also called a side-light-emitting fiber or an illuminating fiber. Produced by the current known optical fiber technology, the whole-body light-emitting optical fiber is composed of a cladding 201, a core 202, and a scatterer 203. The cladding 201 is coated on the outer surface of the core 202, and the scatterer 203 is distributed on the core with a certain density and depth. The inner surface of the layer 22, wherein the refractive index of the cladding layer 201 is greater than the refractive index of the core layer 202, and the scatterer 203 is made of a material different from the refractive index of the core layer 202, and the cladding layer 201 and the core layer 202 constitute a circular waveguide structure. The guided light propagates in the core layer 02, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com