Inserting type fishplate-free rail joint connector

A joint connector and fish plate technology, which is applied to the joints, tracks, roads and other directions of rails, can solve the problems of large assembly workload, peeling, and buckle, and achieve reasonable structural design, small maintenance workload, and bearing capacity. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

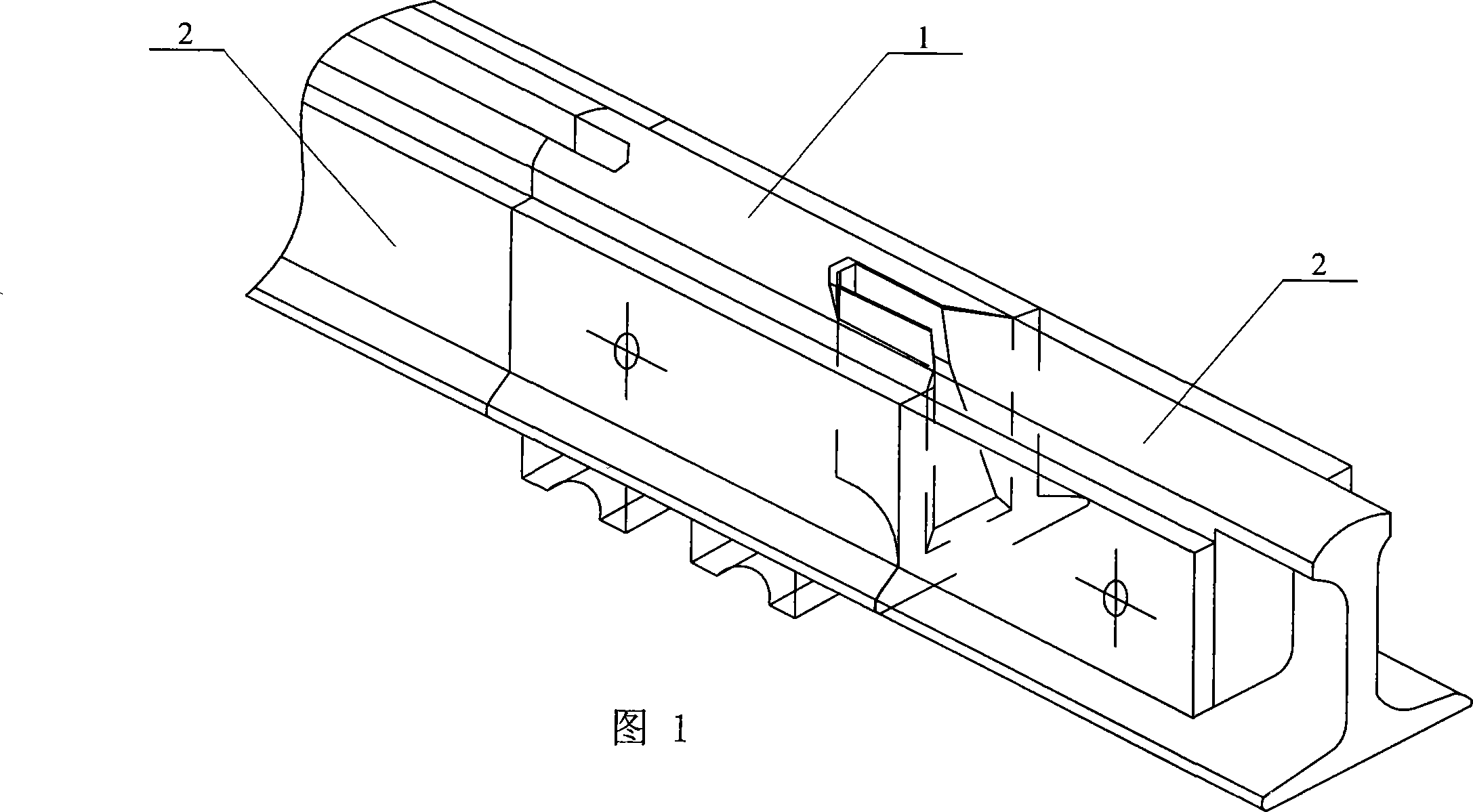

specific Embodiment approach 1

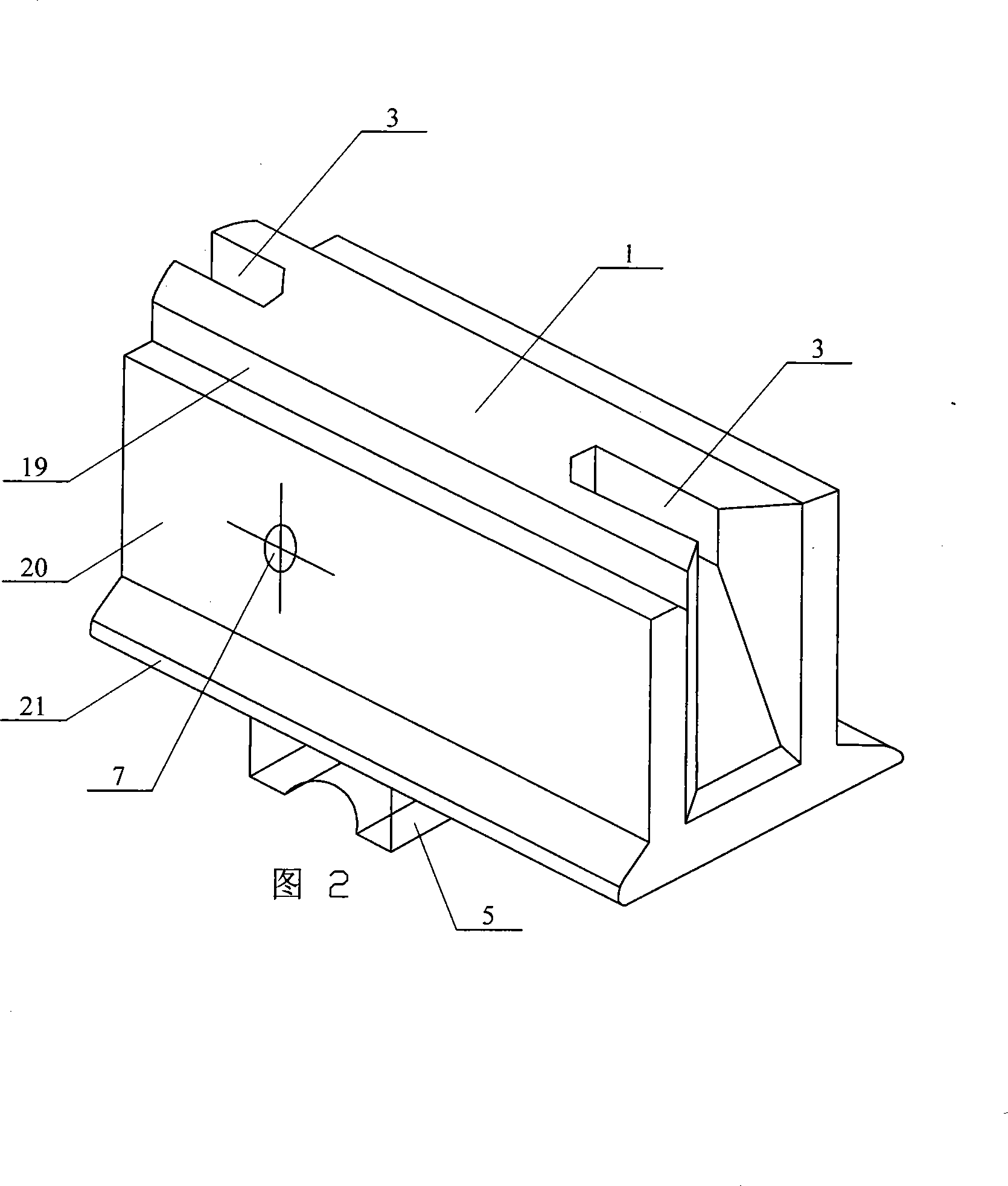

[0007] Specific embodiment 1: This embodiment is described with reference to Figures 1 to 4. This embodiment is composed of a static rail 1 and a moving rail 2; The connecting groove 3, and the connecting groove 3 is set on the central axis of the static rail 1, and one end of the moving rail 2 is provided with a connecting tenon 4 matching with the connecting groove 3, and the connecting tenon 3 is arranged on the moving On the central axis of the rail 2, the insertion slots 3 at both ends of the static rail 1 are equipped with a plug-in tenon 4 that transitions dynamically with it, and the cross-section shape of the other end of the moving rail 2 is the same as that of the 60 rail. At least two bases 5 are arranged on the lower end surface of the rail 1 along the length direction, the middle part of the lower end surface of the base 5 is a circular arc surface 6, and the corresponding positions on the static rail 1 and the moving rail 2 are horizontally provided with wire con...

specific Embodiment approach 2

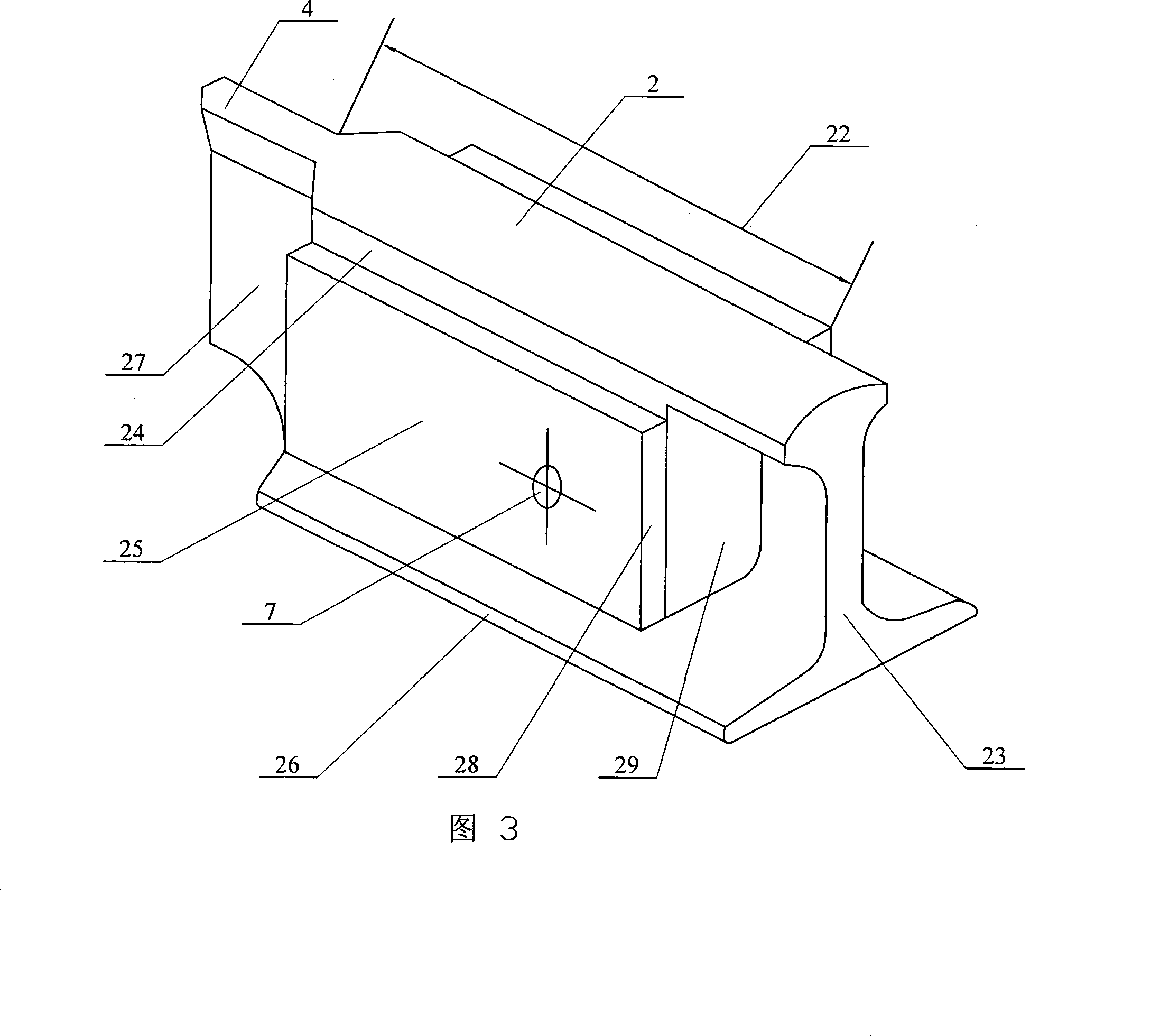

[0008] Specific embodiment two: This embodiment is described in conjunction with Fig. 2, Fig. 4, and Fig. 6. The insertion groove 3 of this embodiment is composed of an inner end face 8, a front side, a rear side, a bottom end face 11, and an outer slope 12; The inner end surface 8 of the connection groove 3 is a V-shaped end surface, and the front side of the insertion groove 3 is composed of a first vertical surface 13, a first inclined surface 14 and a second inclined surface 15. The inner end of the first vertical surface 13 and the The inner end of the first slope 14 is connected with the front end of the V-shaped end face, the lower end of the first vertical surface 13 is connected with the upper end of the first slope 14, the lower end of the first slope 14 is connected with the front end of the bottom end surface 11, and the first vertical The outer end of the surface 13 and the outer end of the first inclined plane 14 are respectively connected with the inner end of th...

specific Embodiment approach 3

[0009] Specific Embodiment Three: This embodiment is described in conjunction with FIG. 5 . The distance H1 between the first vertical surface 13 and the second vertical surface 16 of the insertion groove 3 of this embodiment is 30mm, and the bottom end surface of the insertion groove 3 The width W1 of 11 is 50 mm. Such setting has the advantage of good connection stability. Other components and connections are the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com