Automatic receiving centralizing device for giant engineering tyre wire cord fabric

A centering device and engineering tire technology, which is applied in the directions of transportation and packaging, winding strips, thin material processing, etc., to achieve the effect of synchronous operation speed and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

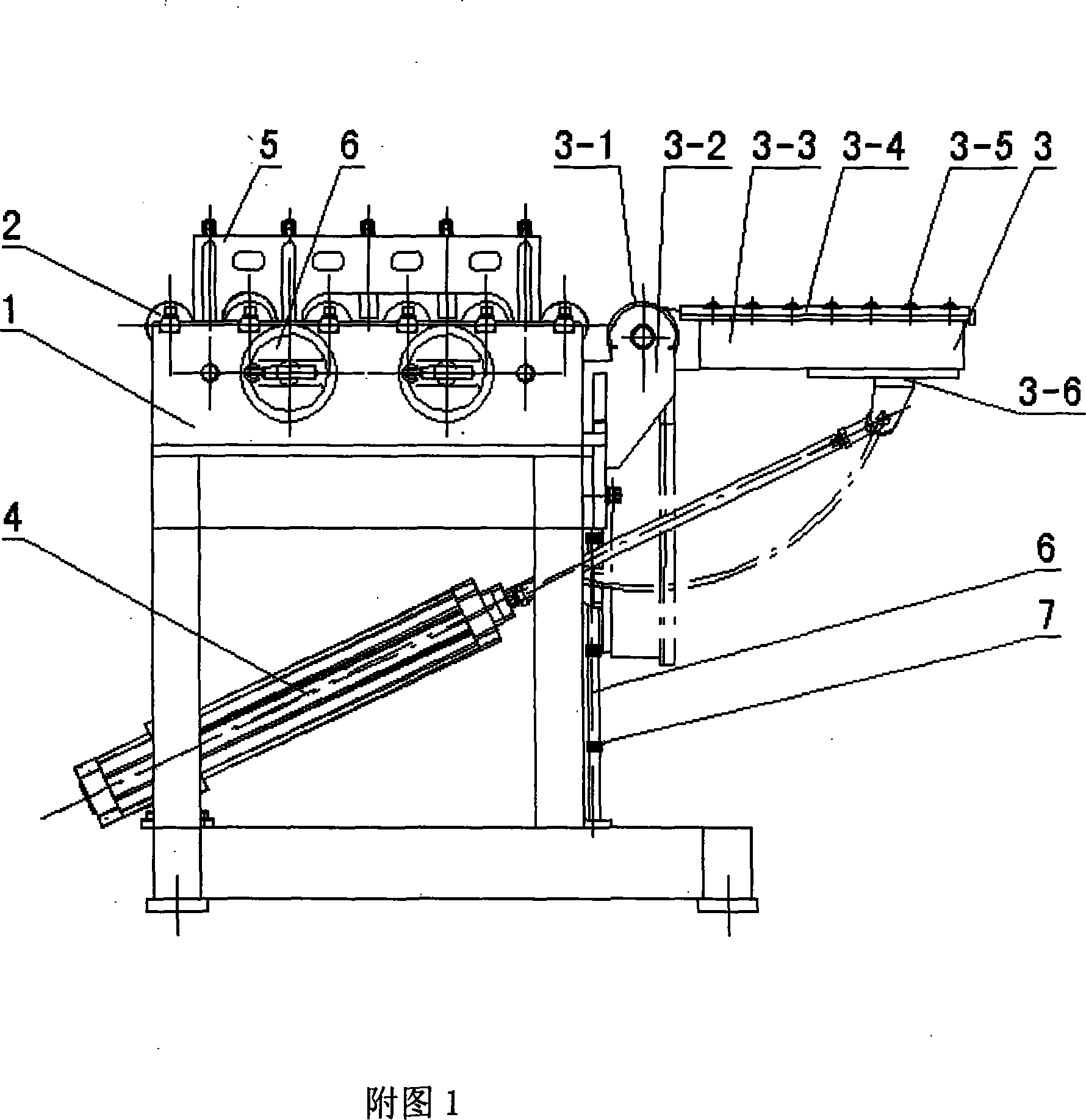

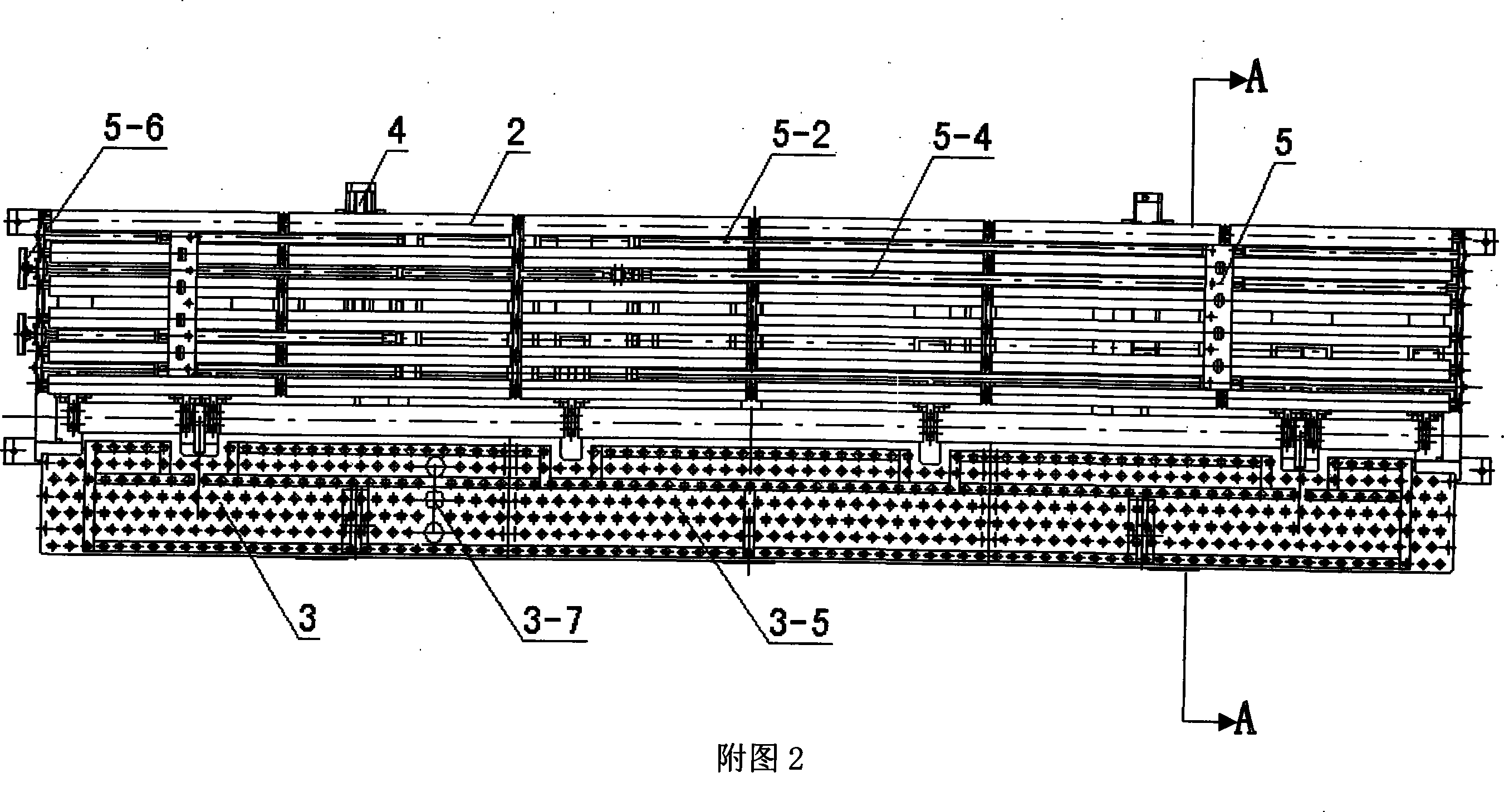

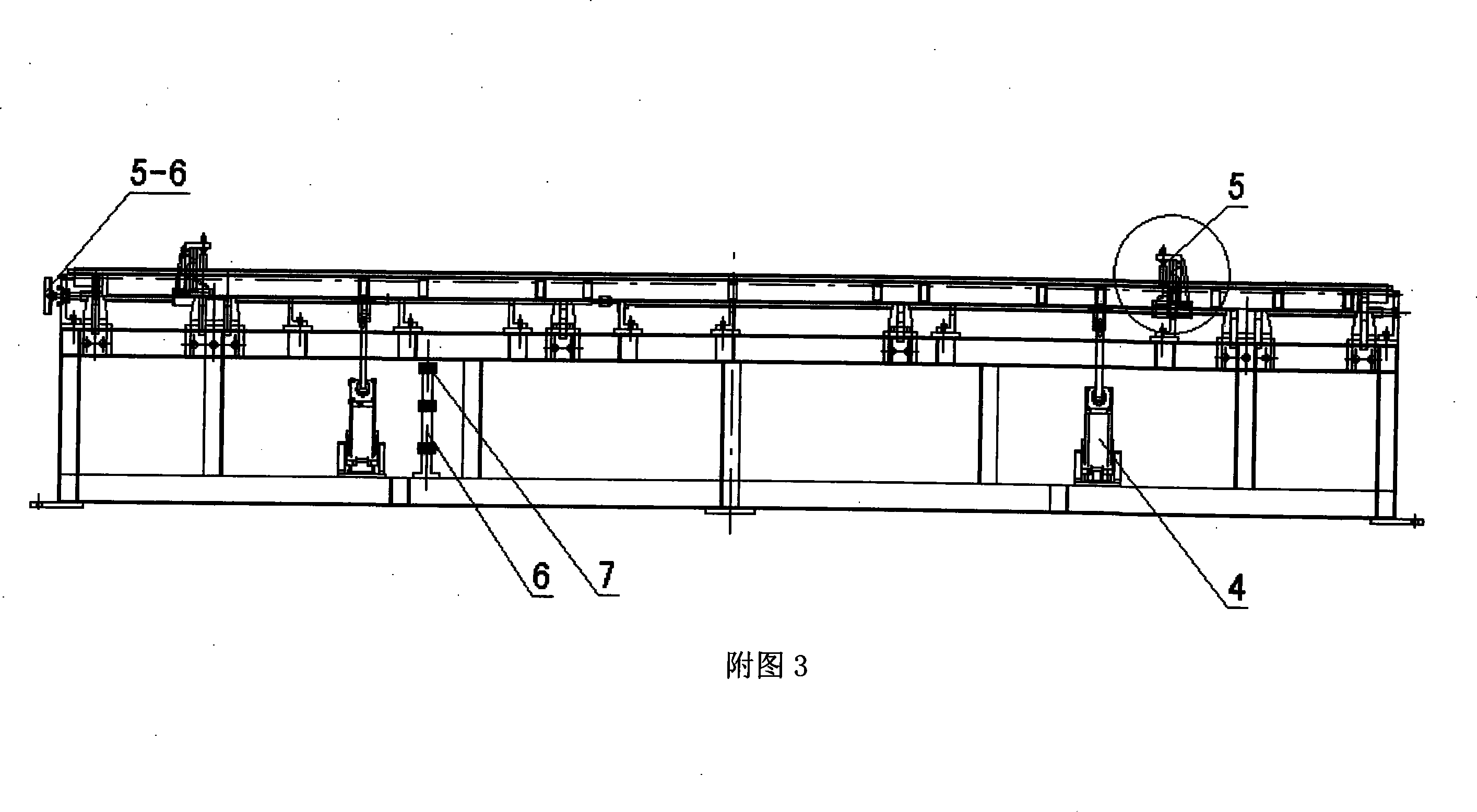

[0014] A giant engineering tire steel cord automatic receiving and centering device provided by the present invention is composed of a frame, a conveying roller group, a receiving and turning plate device, a double-acting cylinder group, a centering device, and a photoelectric sensor system; its characteristics Yes: the receiving turning device 3 is movably connected to the front end of the frame 1, its input end is connected to the output end of the preceding sequence, and the output end is connected to the conveying roller group 2 installed on the upper part of the frame 1; 3. The lower part is symmetrically equipped with support plates 3-6 and the support plates 3-6 are respectively movably connected with the output ends of the double-acting cylinder group 4; the centering device 5 is arranged on the upper part of the frame 1 plane and separately installed 1. The conveying roller group 2 on the upper part is positioned symmetrically on both sides; the overall frame 1 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com