Low flat plate semitrailer turnover board device

A semi-trailer and flat-bed technology, which is applied in the field of semi-trailer and low-bed semi-trailer flipping floor device for loading transport vehicles. It can solve the problems of small ground clearance, inconvenient assembly, inspection and repair of rear axles and accessories, and improve safety. , Improve maintenance efficiency, facilitate operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

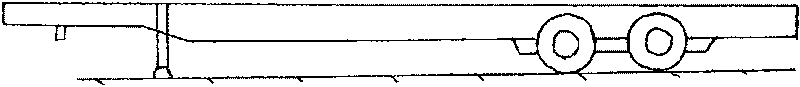

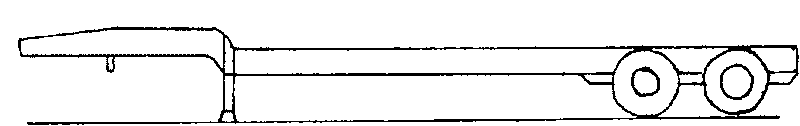

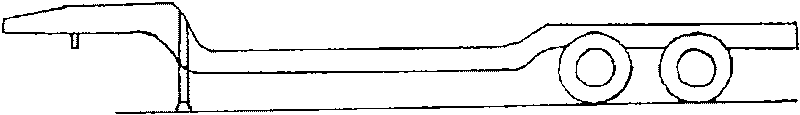

[0028] Such as Figure 2-3 As shown, the front beam 1, the middle beam 4 and the rear beam 5 are welded into one body with the left and right longitudinal beams of the semi-trailer respectively. The flap frame 2 is assembled and welded by two types of steel with different specifications, and the protective plate 3 is welded on the upper surface, and the flap bushing 7 is respectively welded on the front beam 1 and the flap frame 2, and then the flap frame 2. The flap shaft 6 is assembled with the front beam 1, and the two ends of the flap shaft 6 are respectively locked with cotter pins, so that the flap frame 2 can rotate around the flap shaft 6 on the front beam. According to the position of the shaft, The flap frame can be turned over 95° to 120°; fixed poles are installed on the flap frame 2 and the bottom frame to prevent the flap frame from falling down and hurting people. The flap frame 2 is a front and rear symmetrical device, and the nut 10 is tightened by the pressi...

Embodiment 2

[0031] Two beams are welded on the left and right longitudinal beams of the semi-trailer, that is, only one flap frame is arranged, and other structures are the same as in embodiment 1.

[0032] The present invention is also applicable to the use of car bodies of other models.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com