Auxiliary frame of passenger car

A technology for subframes and passenger cars, which is applied to vehicle parts, substructures, transportation and packaging, etc., and can solve the problems that the role of subframes has not attracted enough attention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

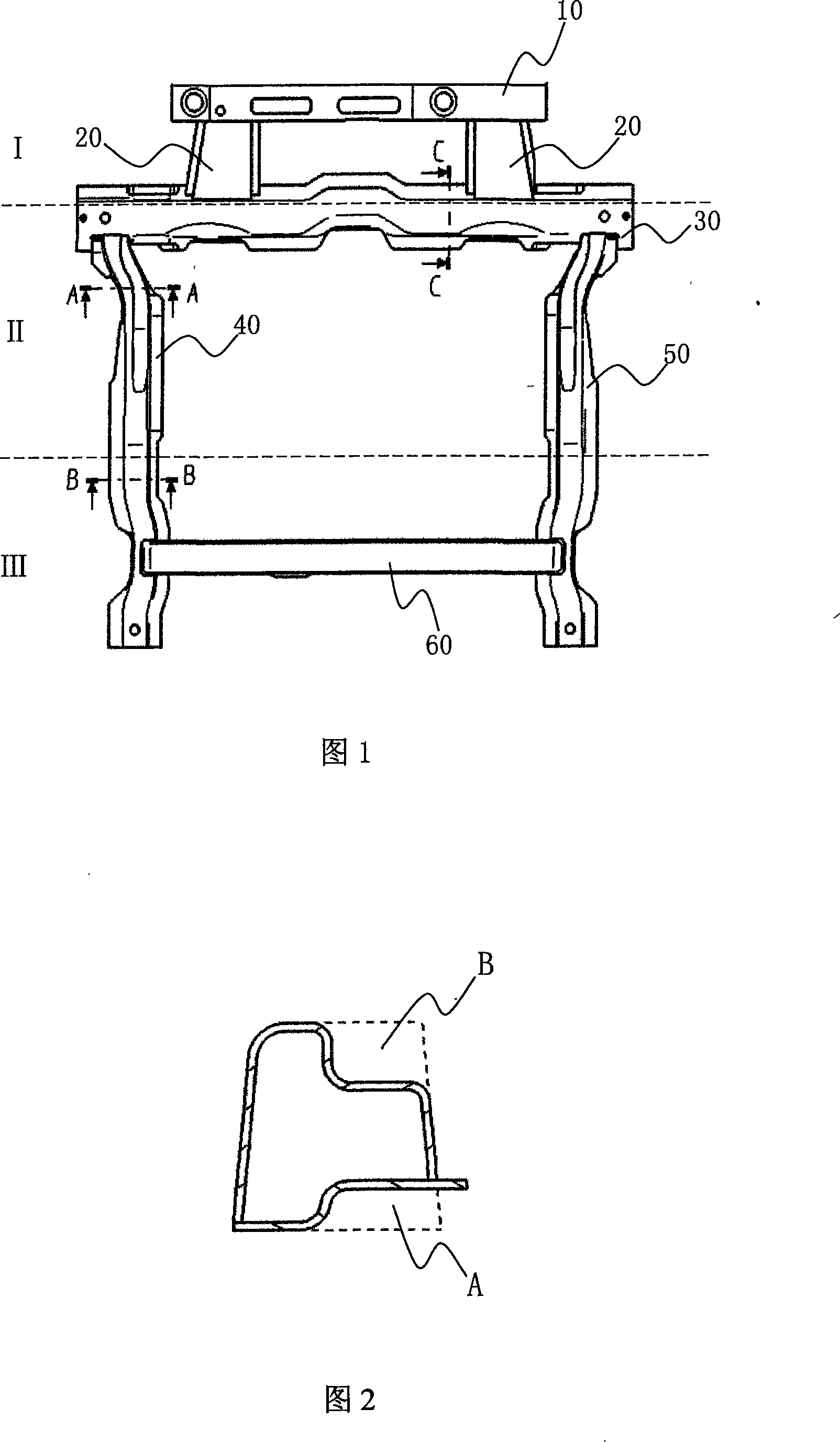

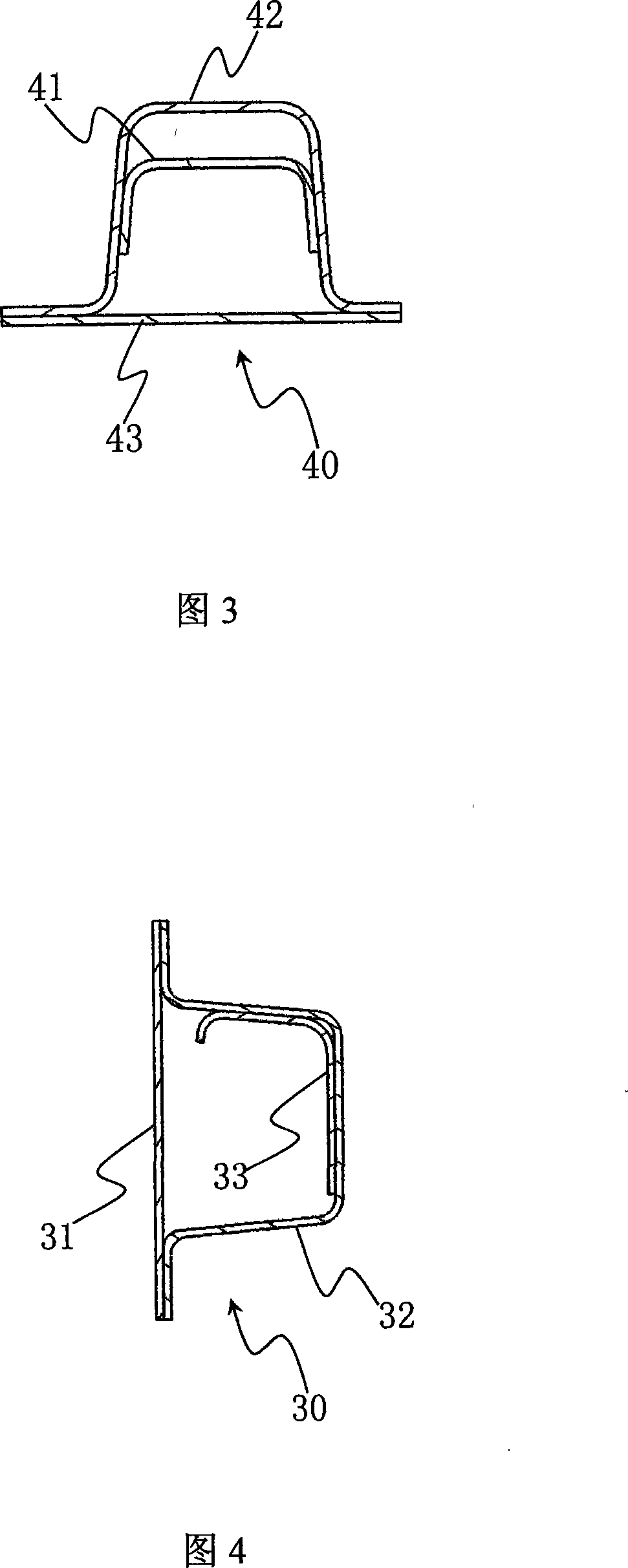

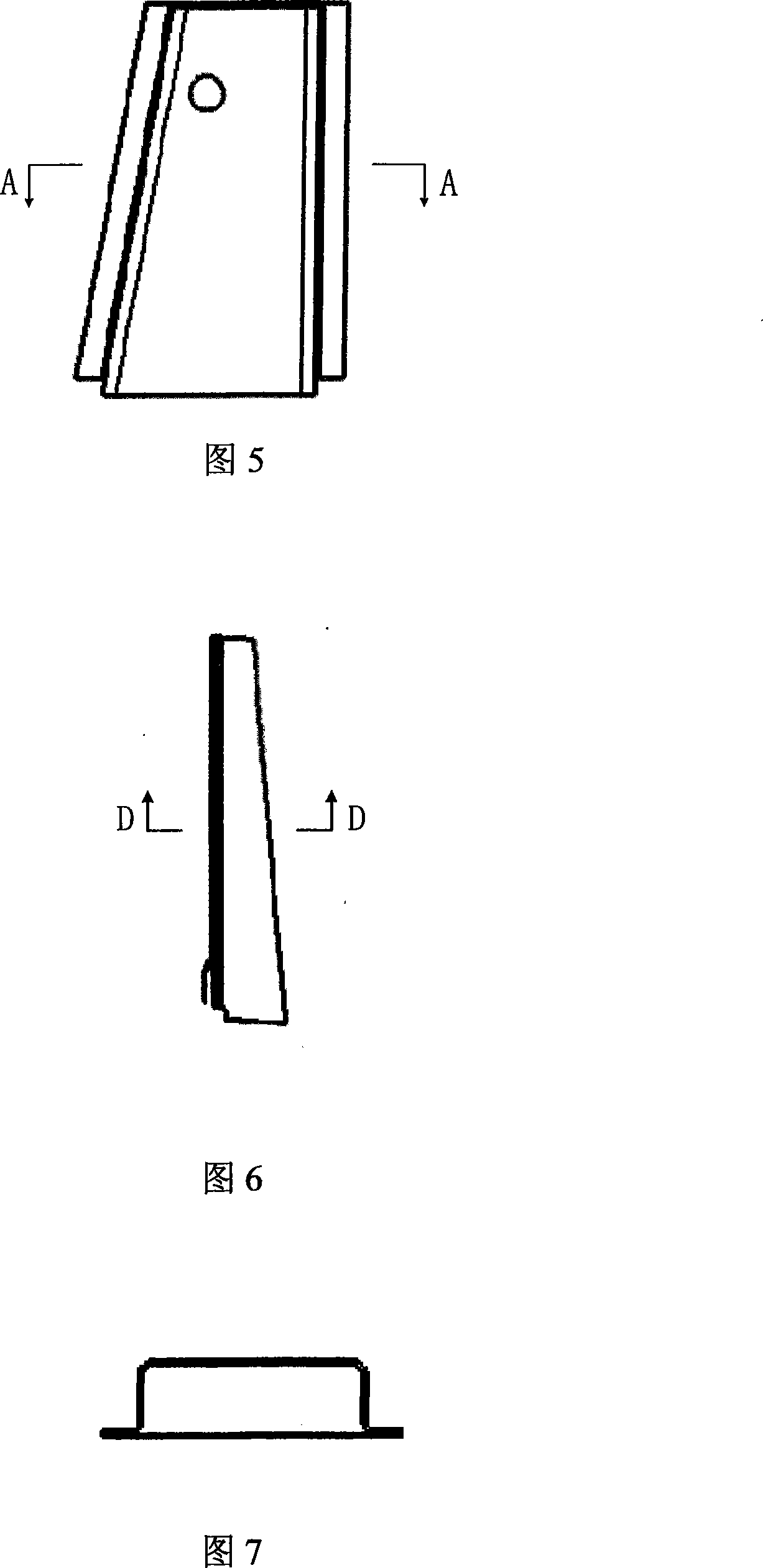

[0013] A sub-frame of a passenger car, which has a water tank support beam 10 placed horizontally from front to back along the front and rear direction of the vehicle. The front beam 30, left and right longitudinal beams 40, 50 and rear beam 60 are welded to form a roughly square frame. 10 and the front beam 30 are symmetrically arranged with left and right transition beams 20, including the front side area I where the left and right transition beams 20 are located, and the rear side of the left and right transition beams 20 to the rear beam 60. The area II between the front side and near the rear beam 60 is an energy-absorbing deformation area.

[0014] The compressive and / or flexural strengths of the left and right transition beams 20 in the area I are smaller than the compressive and / or flexural strengths of the left and right longitudinal beams 40, 50 in the area II.

[0015] In order to realize the design in which the compressive and / or flexural strength of the above-ment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com