Chiasma tendon rope three-joint under-driven robot finger device

A robot finger, underactuated technology, applied in the field of anthropomorphic robots, can solve the problems of unreliable grasping performance, decreased decoupling effect, and affect the appearance, and achieve the effects of reliable performance, simple structure, and easy installation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The content of the specific structure and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

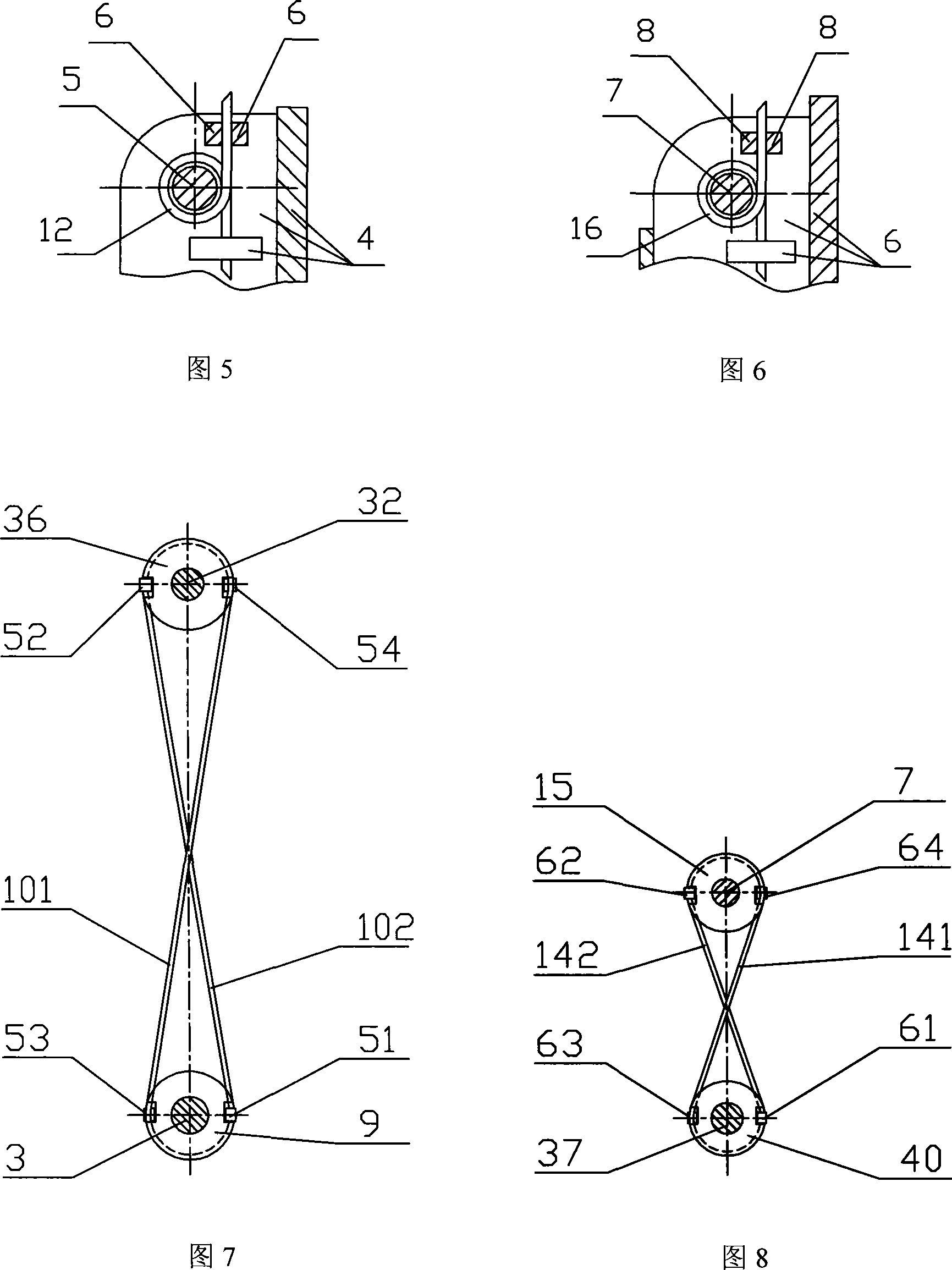

[0041]An embodiment of a cross tendon rope three-joint underactuated robot finger device designed by the present invention is shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5, Fig. 6, Fig. 7 and Fig. 8, including a base 1. Motor 2, reducer 17, first gear 18, second gear 19, proximal joint shaft 3, first middle finger segment 4, second middle finger segment 6, middle joint shaft 5, distal joint shaft 7, end finger Section 8; said motor 2 and speed reducer 17 are affixed to base 1, the output shaft of motor 2 is connected to the input shaft of speed reducer 17, and the output shaft of speed reducer 17 is affixed to said first gear 18, The first gear 18 meshes with the second gear 19, the second gear 19 is fixedly connected with the said proximal joint shaft 3, the proximal joint shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com